Sprag-type bidirectional overrun clutch based on elastic piece control

An overrunning clutch, elastic plate technology, applied in the direction of one-way clutch, clutch, mechanical equipment, etc., can solve the problems of short life, low reliability and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

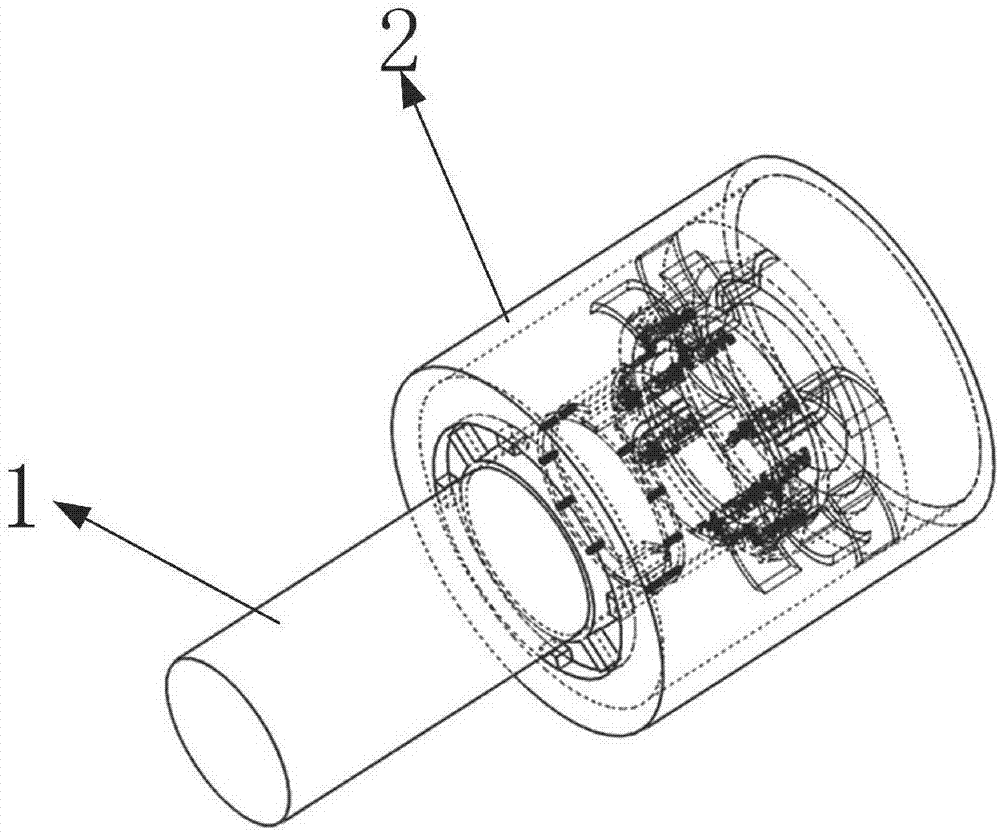

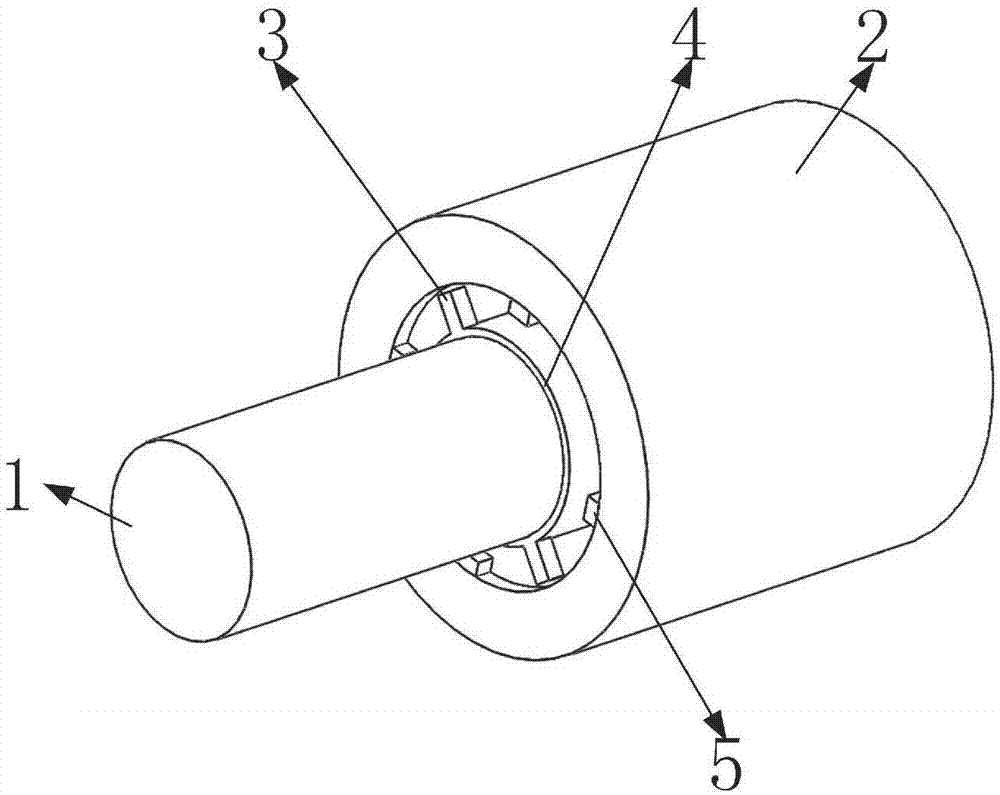

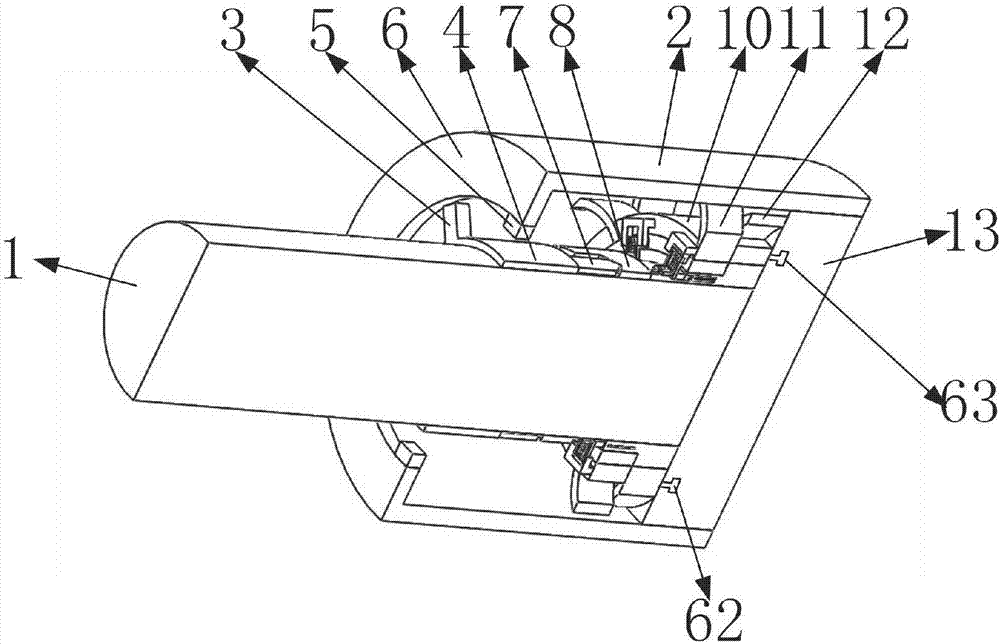

[0035] like figure 1 , 2, 3, it includes drive shaft 1, outer ring 2, first drive block 3, drive sleeve 4, second drive block 5, connecting ring 6, toggle block 7, connecting sleeve 8, inner ring 10, first Elastic sheet 11, T-shaped ring groove 63, T-shaped ring 62, first guide groove 49, first square groove 50, second elastic sheet 12, fixed wheel 13, toggle groove 14, first trigger mechanism 15, seventh Spring 55, second driving slope 54, first connecting block 16, first fixing ring 17, second trigger mechanism 18, second connecting block 19, second fixing ring 20, third fixing ring 21, second guide groove 22 , the second square groove 23, the second limit block 56, the first limit block 60, the first drive bar 42, the second drive bar 43, the first guide groove 47, the second guide groove 48, the first drive slope 51 ,like image 3 As shown, wherein the fixed wheel 13 end face has a T-shaped ring groove 63, and one end of the fixed wheel 13 that opens the T line ring gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com