Prefabricated assembly-type substation cabin foundation

A technology of prefabricated assembly and substation, applied in the field of cabin foundation, can solve the problems of long cycle, difficult support, easy to wrong mold deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

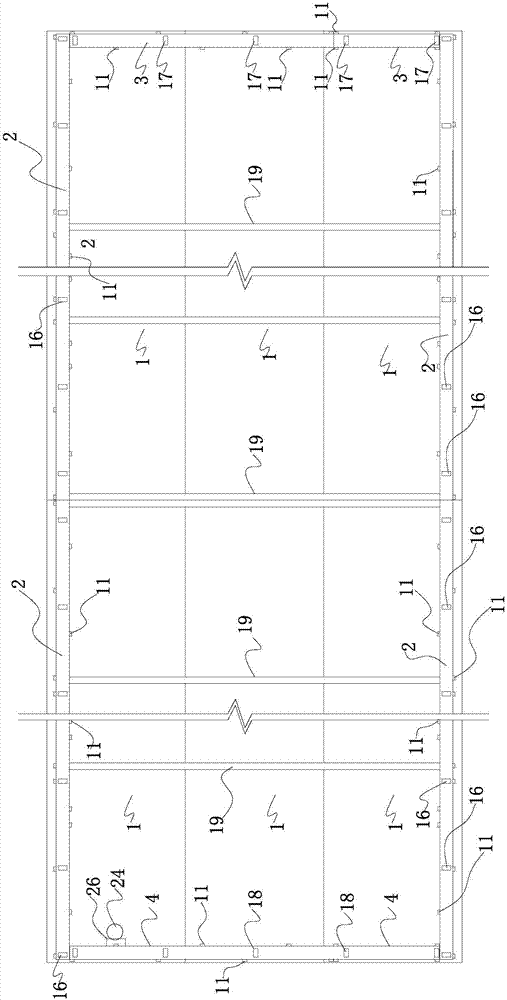

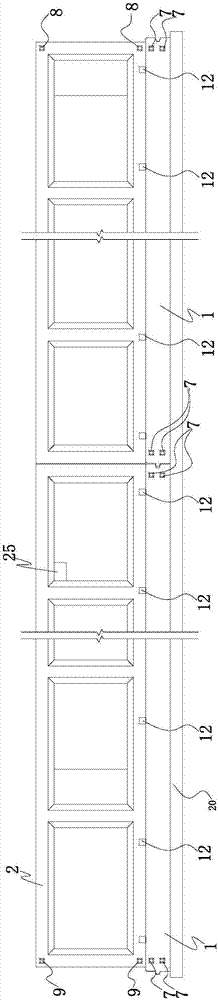

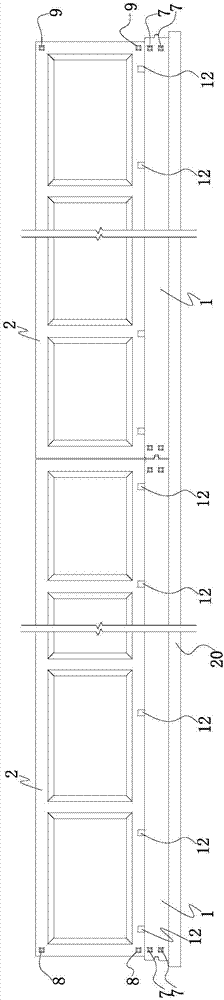

[0053] The following with attached Figure 1 to Figure 13 A prefabricated substation cabin foundation of the present invention will be further described in detail.

[0054] For a prefabricated substation cabin foundation of the present invention, please refer to Figure 1 to Figure 13 The relevant figures in the figure include a base plate assembly and a wall panel assembly fixed on the base plate assembly. The base plate assembly includes one less prefabricated base plate 1. The prefabricated base plate 1 is detachably assembled and fixed. The wall panel assembly includes Two rows of side wall assemblies arranged in parallel and front-end blocking wall panels 3 and rear-end blocking wall panels 4 arranged between the front ends and rear ends of the two rows of side wall assemblies, each row of side wall assemblies It includes at least one prefabricated side wall panel 2, the front end block wall panel 3 and the rear end block wall panel 4 are prefabricated panels, the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com