Nano barium hydroxide/graphene nano composite material and preparation method

A nano-composite material, barium hydroxide technology, applied in graphene, chemical instruments and methods, calcium/strontium/barium oxide/hydroxide, etc., can solve the problems of small barium carbonate crystals, improve the reinforcement strength, Simple preparation process and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

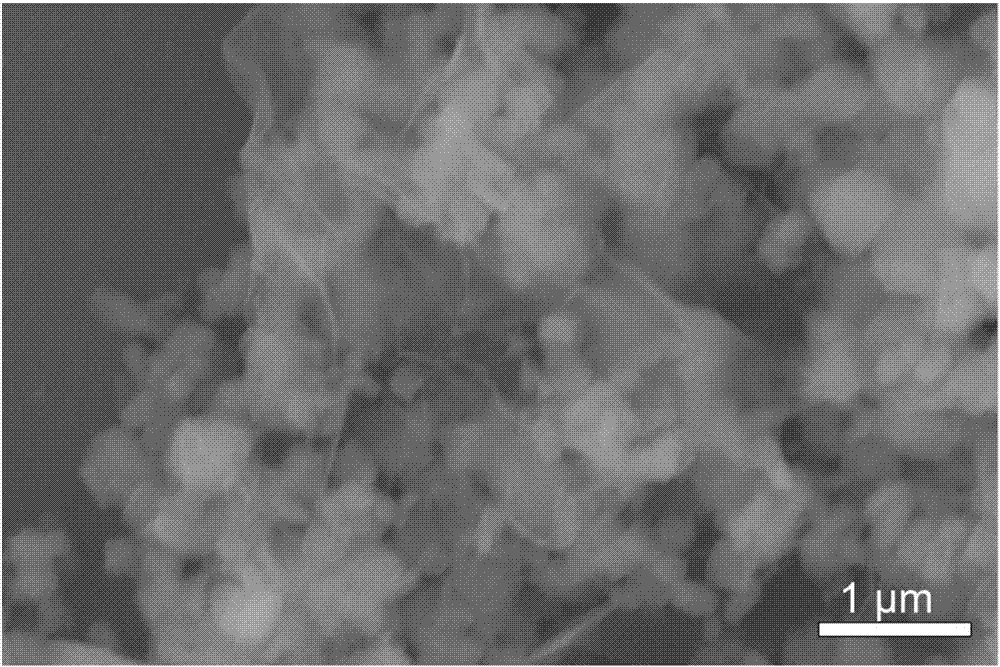

Image

Examples

preparation example Construction

[0019] The invention provides a preparation method of nano barium hydroxide / graphene nanocomposite material, wherein the mass percentage of graphene is 1%-3%, and the rest is barium hydroxide. It is mainly prepared by the following steps:

[0020] Step 1, preparation of graphene oxide: adding commercially available graphite powder into concentrated sulfuric acid. The above solution was stirred in an ice-water bath. Slowly add potassium permanganate to concentrated sulfuric acid. Quickly add sodium nitrate to concentrated sulfuric acid. The above mixture was further stirred for 30 min in an ice-water bath. Then raise the temperature to 30-50°C, and continue to stir until the solution is viscous. Add deionized water to the viscous material, and raise the temperature to 80-90°C and continue stirring for 2-5 hours. Hydrogen peroxide was then added dropwise to the solution. Wait for the temperature to cool to room temperature. 6000-8000 rpm, 5-20 minutes, washing with water,...

Embodiment 1

[0023] Barium hydroxide octahydrate (molecular formula is Ba(OH) 2 ·8H 2 O) mix with graphene oxide powder and add in dehydrated alcohol and be placed in the airtight container that is filled with nitrogen. Wherein the mass ratio of barium hydroxide octahydrate, graphene oxide and absolute ethanol is 1:62.5:100. The above mixture was heated and stirred vigorously to 180 degrees. After 2 hours of heat preservation, it was naturally cooled to room temperature. The cooled solution was poured into a beaker and dried in a vacuum oven at 30°C for 6 hours to obtain the nano-barium hydroxide / graphene nanocomposite material.

Embodiment 2

[0025] Barium hydroxide octahydrate (molecular formula is Ba(OH) 2 ·8H 2 O) mix with graphene oxide powder and add in dehydrated alcohol and be placed in the airtight container that is filled with nitrogen. Wherein the mass ratio of barium hydroxide octahydrate, graphene oxide and absolute ethanol is 1:100:100. The above mixture was heated and stirred vigorously to 190°C. After 4 hours of heat preservation, it was naturally cooled to room temperature. The cooled solution was poured into a beaker and dried in a vacuum oven at 40°C for 9 hours to obtain the nano-barium hydroxide / graphene nanocomposite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com