Modular assembly type automatic lifting tower crane wall-attached working platform

An automatic lifting and working platform technology, applied in the direction of lifting devices, cranes, etc., can solve the problems of falling from high altitude and falling objects, difficulty in setting up the operation platform, time-consuming and labor-intensive, etc., to save repeated labor, not easy to fall from high altitude and high-altitude falling Goods, high promotional value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] Traditional operating platforms are all built at high altitude or assembled at high altitudes. The new platform operating frame is assembled on the ground, using the principle of pylons, high altitude installation, one-time installation in place, and subsequent electric lifting. It is convenient and fast, and reduces the workload of a large amount of high-altitude assembly of traditional frames, thereby effectively reducing the safety risks of high-altitude operations.

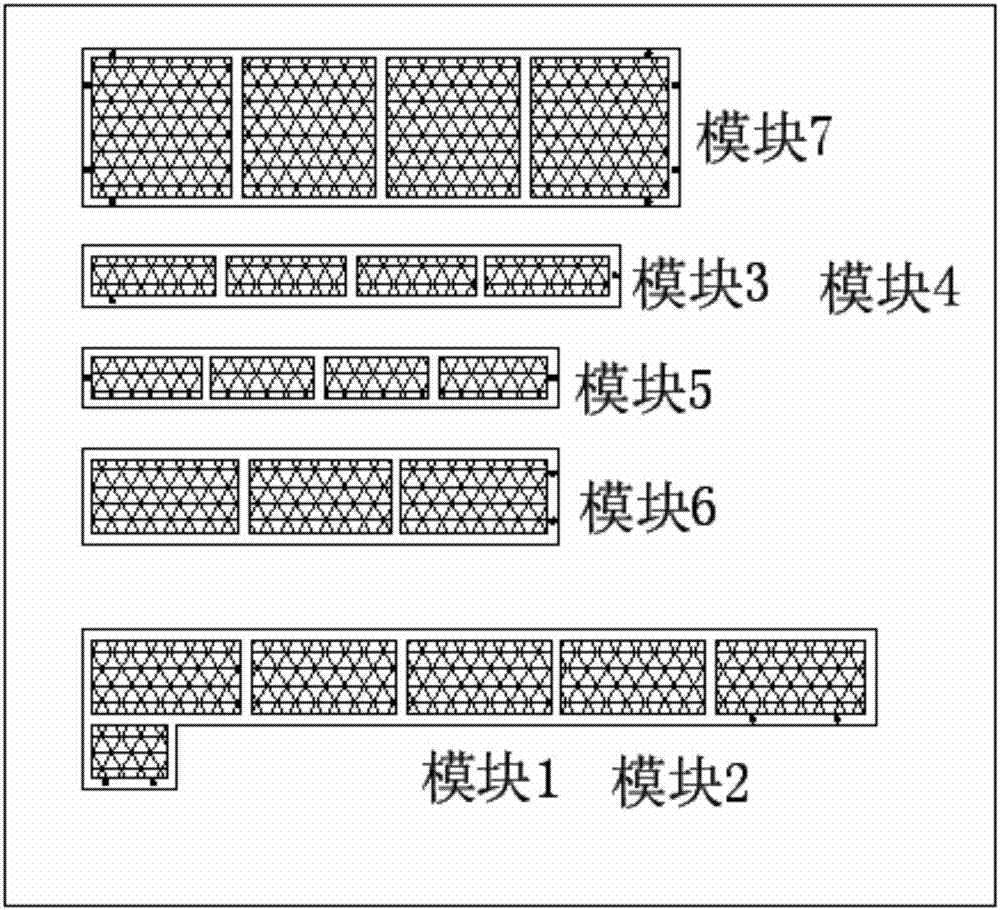

[0027] Use the tower body to carry out the general-purpose and tool-based design of the operating platform. The tower body is used as the support and fixed body; the overall processing and production of the component diagrams are carried out, and the pendants, the operating platform and the guardrail are installed.

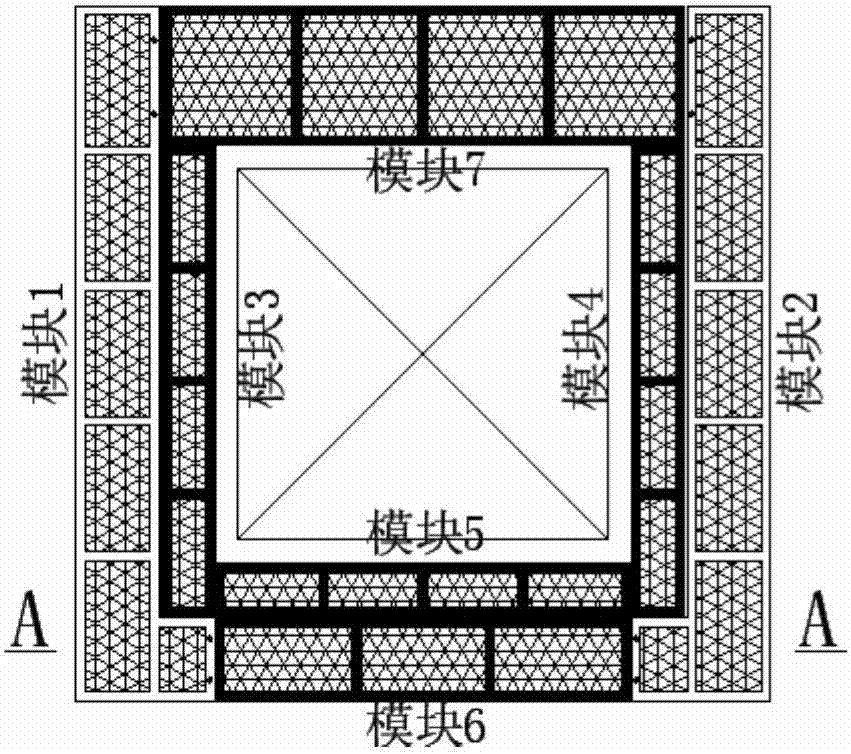

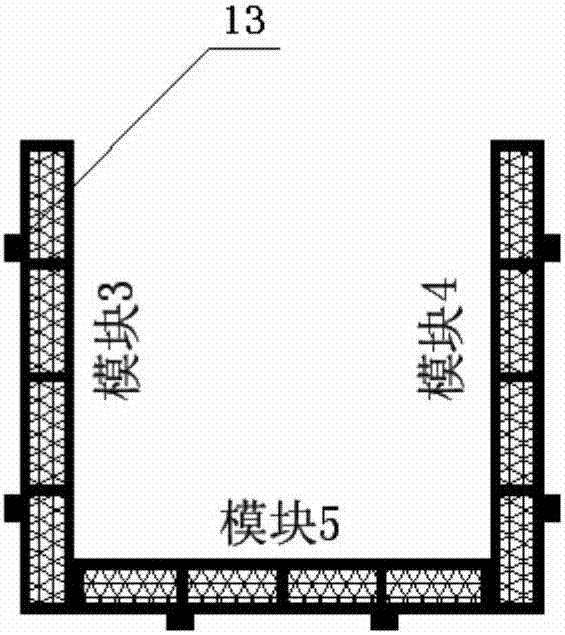

[0028] A modular assembly type automatic lifting tower crane attached wall working platform is composed of an operating platform and an automatic lifting system. The operating platform consists ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com