An anti-jamming z-axis balance device

A balancing device and anti-jamming technology, which is applied to metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as jamming, different frictional changes, jamming, etc., to reduce processing accuracy and reduce Requirements for parallelism and the effect of reducing coaxiality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

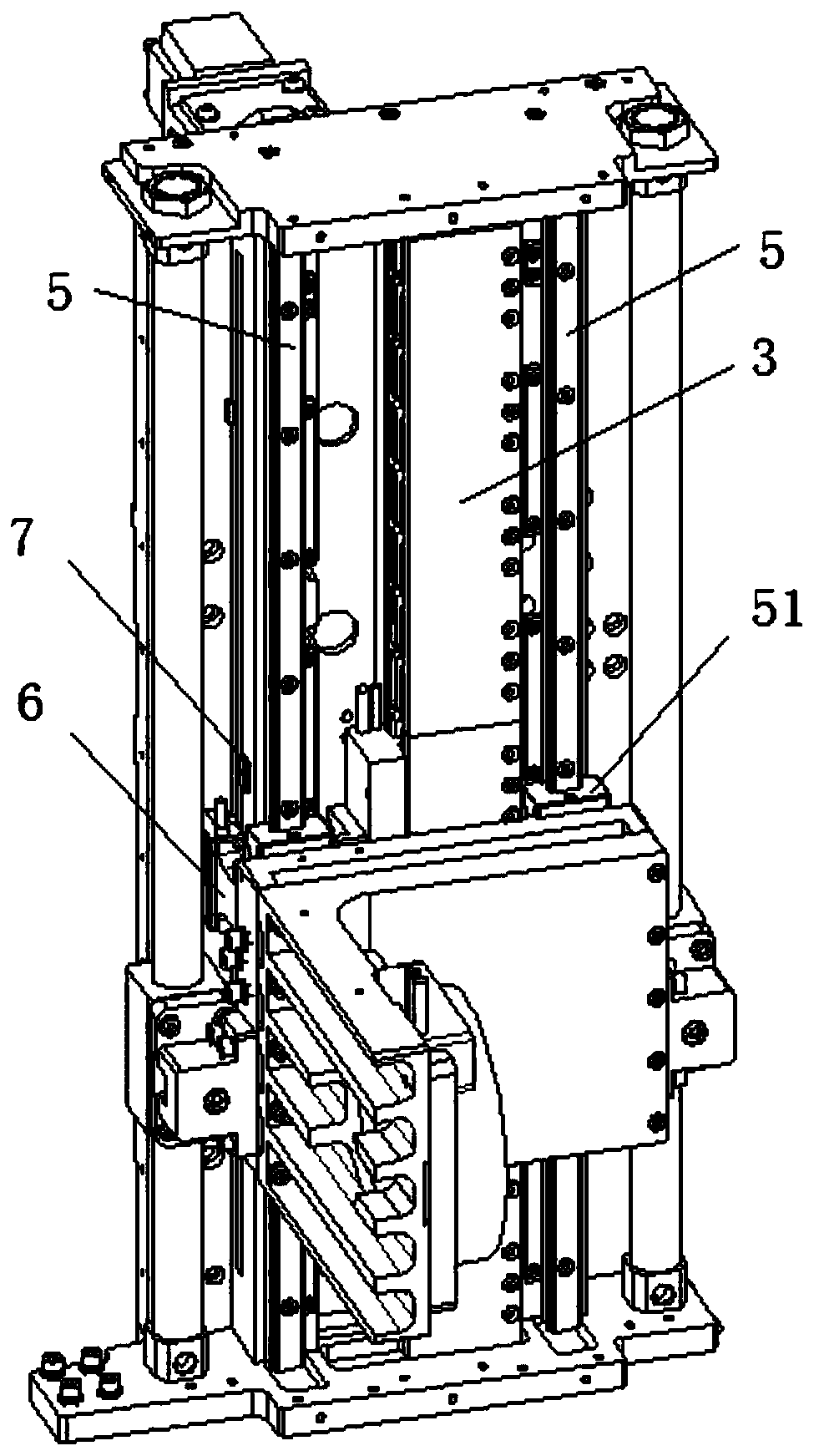

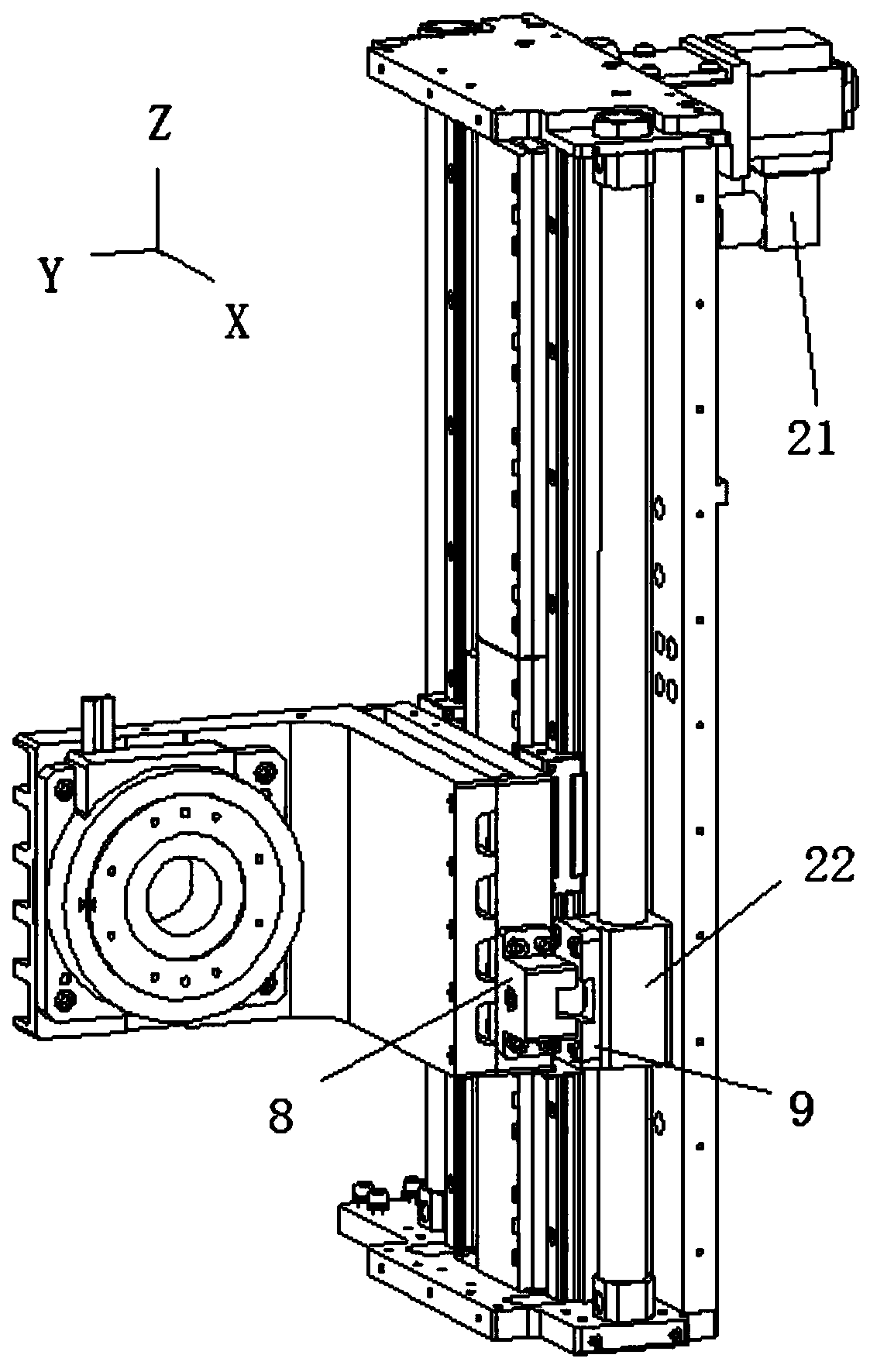

[0017] see Figure 1 to Figure 4 , an anti-jamming Z-axis balancing device, comprising a linear motor module 3, a Z-axis moving module 4 driven by the linear motor module 3, a slider 51 connected to the Z-axis moving module 4, and a sliding block engaged with the slider 51 Rail 5. There are two slide rails 5, and the two slide rails 5 are arranged in parallel and along the Z-axis direction, and the linear motor module 3 drives the Z-axis moving module 4 to move along the Z-axis.

[0018] The anti-jamming Z-axis balancing device also includes two rodless cylinder blocks 2 arranged in parallel, a rodless cylinder slider 22 installed on the rodless cylinder body 2, and a chute connected with the rodless cylinder slider 22 Part 9, the fixing part 8 connected with the Z-axis moving module 4, the fixing part 8 is connected with a sliding column 82, the fixing part 8 is provided with a fixing groove 81 for installing the sliding column 82, and the sliding column 82 is fixed with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com