Variable-cutter-gap two-degree-of-freedom hydraulically-driven sugarcane cutting device

A technology of cutting device and degree of freedom, applied in harvesters, agriculture, application, etc., can solve the problems of reducing the cutting efficiency of sugarcane devices, adjusting the distance between cutter heads, and being unable to lift the cutter, so as to reduce the broken head rate and cutting loss rate, Higher height and larger output torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

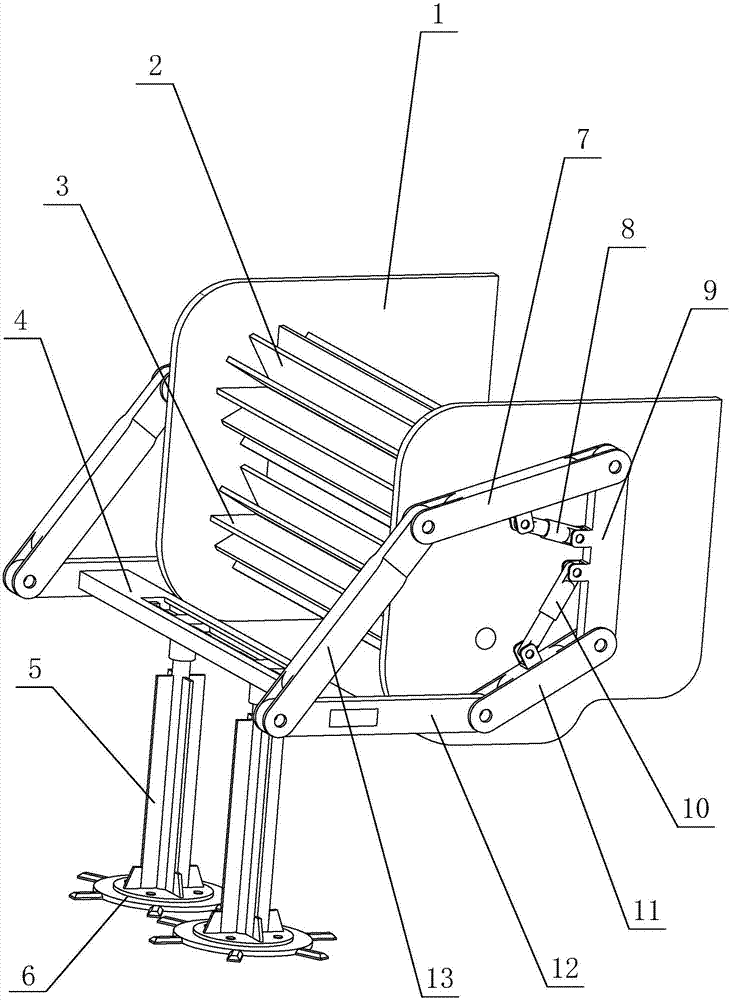

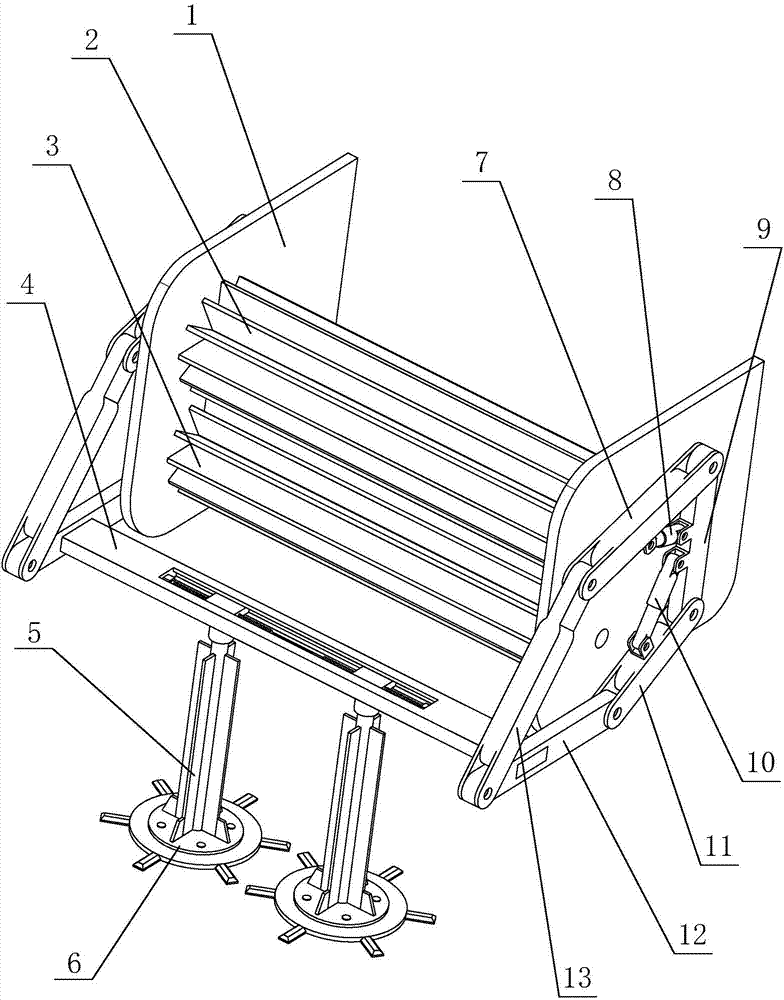

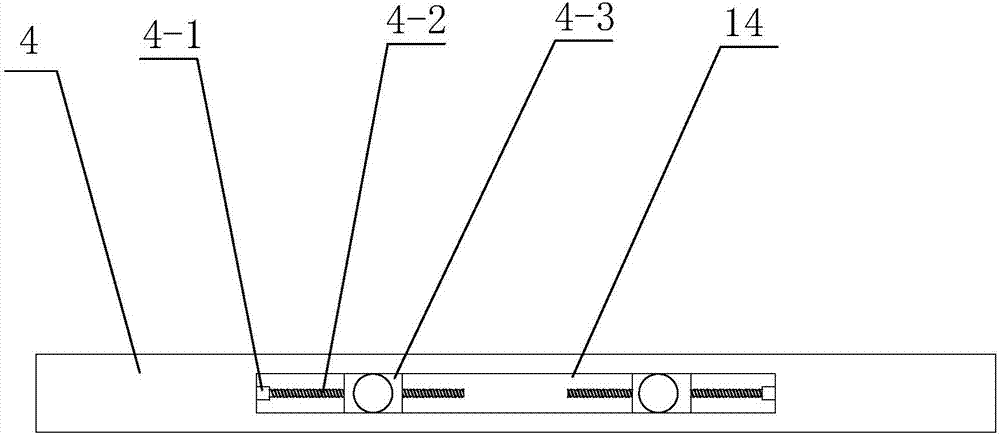

[0019] Such as figure 1 , figure 2 As shown, the two-degree-of-freedom hydraulically driven sugarcane cutting device with variable cutter head clearance includes feeding rollers, two sets of 6 disc cutters, two sets of outer sleeves 5 and two fixed plates 1 arranged in parallel. The feeding rollers include an upper feeding roller 2 and a lower feeding roller 3 arranged in sequence from top to bottom, and the upper feeding roller 2 and the lower feeding roller 3 are parallel to each other and are installed between two fixed plates 1 through a rotating shaft. between. The upper feeding roller 2 and the lower feeding roller 3 can rotate along the rotating shaft. A cutter head rotating shaft is installed on each disc cutter 6, and one end of the cutter disc rotating shaft is fixed on the described disc cutter 6, and its other end penetrates in the outer sleeve 5 and is connected with the disc cutter motor. The difference from the prior art is that it also includes a cutter hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com