Polyurethane composite acoustic material and preparation method thereof

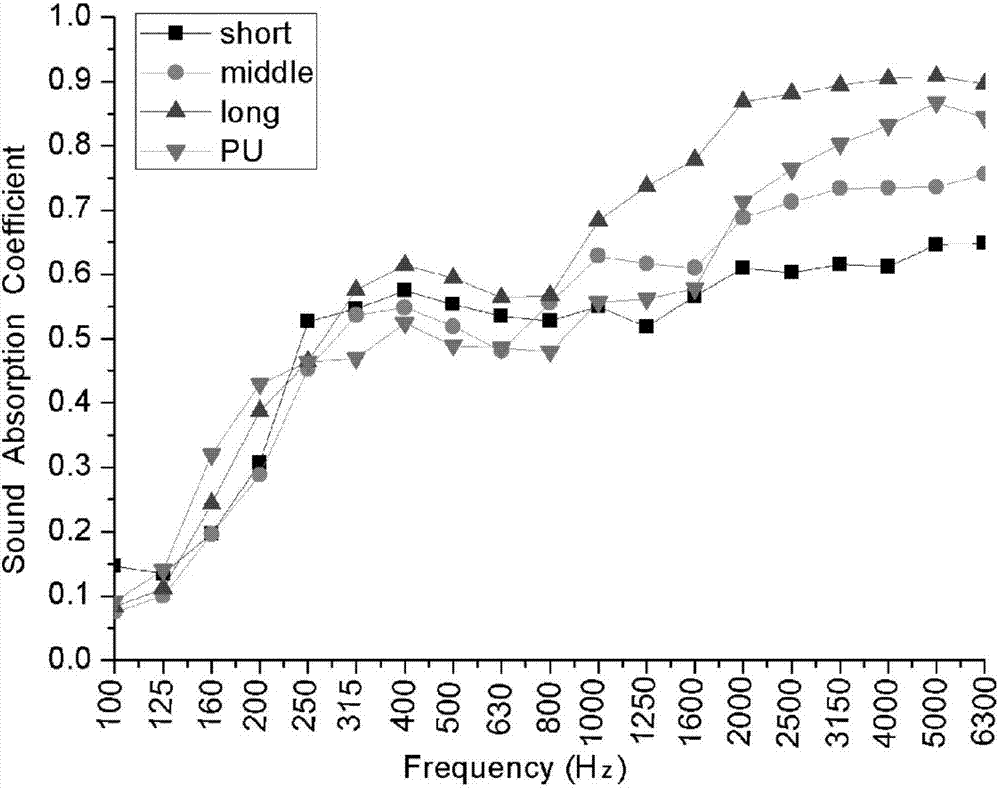

A polyurethane and acoustic technology, applied in the field of polyurethane composite acoustic material and its preparation, can solve problems such as poor low-frequency sound absorption performance, and achieve the effects of low cost, increased degradation ability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A preparation method of polyurethane composite acoustic packaging material, the preparation method may further comprise the steps:

[0028] refer to figure 1 , step 1, 60 parts of polyether polyol 330N, 40 parts of polyether polyol 3630, 3 parts of foaming agent deionized water, 3 parts of foaming agent triethanolamine, 5 parts of foaming agent monofluorodichloroethane HCFC-141b, 0.05 parts of catalyst A1, 1 part of catalyst A33 and 1.8 parts of foam stabilizer silicone oil were mixed in a plastic cup, stirred with an electric mixer at a speed of 1200 rpm at room temperature, and stirred for 5 to 8 minutes to obtain mixture A;

[0029] Step 2. Add 0.2 to 1.5 parts of 1mm to 2mm pine needle fragments, or 0.2 to 1.5 parts of 3mm to 4mm pine needle fragments or 0.2 to 1.5 parts of 5mm to 6mm pine needle fragments into mixture A, and then use an electric mixer to stir fully at a speed of 1200rmp Mixture B was obtained in 5 minutes to 8 minutes;

[0030] Step 3. Add 30 par...

Embodiment 1

[0034] A polyurethane composite acoustic packaging material, the acoustic packaging material is composed of the following components by weight ratio:

[0035]

[0036] The preparation method of the acoustic packaging material is as follows:

[0037] Step 1. Make 5 parts of the formula with exactly the same components and contents: 60 grams of polyether polyol 330N, 40 grams of polyether polyol 3630, 3 grams of deionized water, 3 grams of triethanolamine, 5 grams of HCFC-141b, 0.05 grams A1, 1 gram of A33, 1.8 grams of silicone oil were mixed and added to 5 identical plastic cups, and stirred at room temperature with an electric stirrer at a speed of 1200rmp for 5-8 minutes to obtain mixture A;

[0038] Step 2. Add 0.2g, 0.5g, 0.8g, 1.0g and 1.5g of 1-2mm pine needle fragments into the 5 plastic cups in step 1 respectively, and then use electric mixer to stir fully at 1200rmp for 5-8 minutes respectively get mixture B;

[0039] Step 3. Add 5 parts of 30g of 4,4-diphenylmet...

Embodiment 2

[0043] A polyurethane composite acoustic packaging material, the acoustic packaging material is composed of the following components by weight ratio:

[0044]

[0045] The preparation method of the acoustic packaging material is as follows:

[0046] Step 1. Make 5 parts of the formula with exactly the same components and contents: 60 grams of polyether polyol 330N, 40 grams of polyether polyol 3630, 3 grams of deionized water, 3 grams of triethanolamine, 5 grams of HCFC-141b, 0.05 grams A1, 1 gram of A33, 1.8 grams of silicone oil were mixed and added to 5 identical plastic cups, and stirred at room temperature with an electric stirrer at a speed of 1200rmp for 5-8 minutes to obtain mixture A;

[0047] Step 2. Add 0.2g, 0.5g, 0.8g, 1.0g and 1.5g of 3-4mm pine needle fragments into the 5 plastic cups in step 1, and then use an electric mixer at a speed of 1200rmp to fully stir for 5-8 minutes get mixture B;

[0048] Step 3. Add 5 parts of 30g of 4,4-diphenylmethane diisocy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com