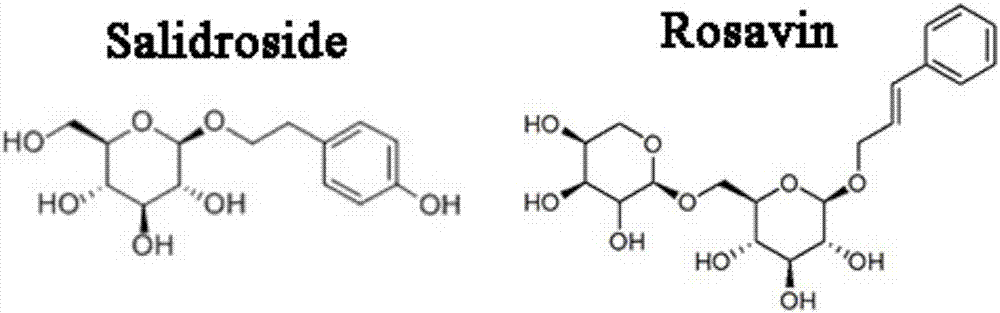

Method for synchronously separating and preparing salidroside and rosavin from rhodiola rosea

A technology for simultaneous separation of salidroside, applied in chemical instruments and methods, preparation of sugar derivatives, organic chemistry, etc. problem, to achieve the effect of easy to form industrialization, increase utilization value, and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] 1) Extraction: 1 kg of Rhodiola root is pulverized, sieved, and the particle size is greater than 60 orders to obtain Rhodiola powder; add 10% ethanol aqueous solution of 8 times the weight of Rhodiola in the obtained Rhodiola powder, which contains low Eutectic solvent (tetraethylammonium chloride: xylitol = 1:1) 9%, reflux extraction, extraction time is 8 hours, continuous extraction 2 times, combined extracts.

[0040] 2) Primary separation and purification: Concentrate the extract to 1 / 4 of the original volume, centrifuge, and pass the supernatant through an expanded bed filled with 0.8 kg of mixed macroporous resin (HPD400A:LSA10:DA201-CIII=1:1.6:3) , Adsorb from bottom to top with a flow rate of 1.5BV / h; after the adsorption is completed, wash from bottom to top with a flow rate of 2BV / h and a dosage of 2.2BV; first elute with 5% ethanol solution from top to bottom Salidroside is produced, the flow rate is 2BV / h, the dosage is 1.5BV, the eluate is collected, conce...

Embodiment 2

[0044] 1) Extraction: 5 kg of rhodiola roots are pulverized, sieved, and the particle size is greater than 60 orders to obtain rhodiola powder; add 50% ethanol aqueous solution of 12 times of rhodiola weight in the obtained rhodiola powder, which contains low Eutectic solvent (tetraethylammonium chloride:glucose=1:2) 5%, reflux extraction, extraction time is 6 hours, continuous extraction 2 times, combined extracts.

[0045] 2) Primary separation and purification: Concentrate the extract to 1 / 4 of the original volume, centrifuge, and pass the supernatant through an expanded bed filled with 5kg of mixed macroporous resin (HPD400A:DA201-CIII=1:5), from bottom to top For adsorption, the flow rate is 2BV / h; after the adsorption is completed, wash from bottom to top, the flow rate of water washing is 3BV / h, and the dosage is 3BV; first use 10% ethanol solution to elute salidroside from top to bottom, the flow rate It is 3BV / h, and the dosage is 2BV. Collect the eluate, concentrate ...

Embodiment 3

[0049] 1) Extraction: 10 kg of rhodiola roots are pulverized, sieved, and the particle size is greater than 60 mesh to obtain rhodiola powder; add 20 times of rhodiola weight 75% ethanol aqueous solution to the obtained rhodiola powder, which contains low Eutectic solvent (tetraethylammonium chloride: xylitol: glucose = 2:1:3) 2%, reflux extraction, extraction time is 4 hours, continuous extraction 2 times, combined extracts.

[0050] 2) primary separation and purification: concentrate the extract to 1 / 4 of the original volume, centrifuge, and pass the supernatant through an expanded bed filled with 8 kg of mixed macroporous resin (HPD400A:LSA10:DA201-CIII=1:1:3), Adsorb from bottom to top with a flow rate of 4BV / h; after the adsorption is completed, wash with water from bottom to top with a flow rate of 4BV / h and a dosage of 4BV; first use 25% ethanol solution to elute the rhododendron from top to bottom Tianside, the flow rate is 4BV / h, the amount of ethanol solution is 3BV,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com