Manual plastic packaging machine for plastic package film product

A technology for film products and plastic sealing machines, which is used in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of strong pungent nose, endanger the health of operators, and difficult to fix the free end, so as to improve the plastic sealing effect, The effect of improving the efficiency of plastic sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

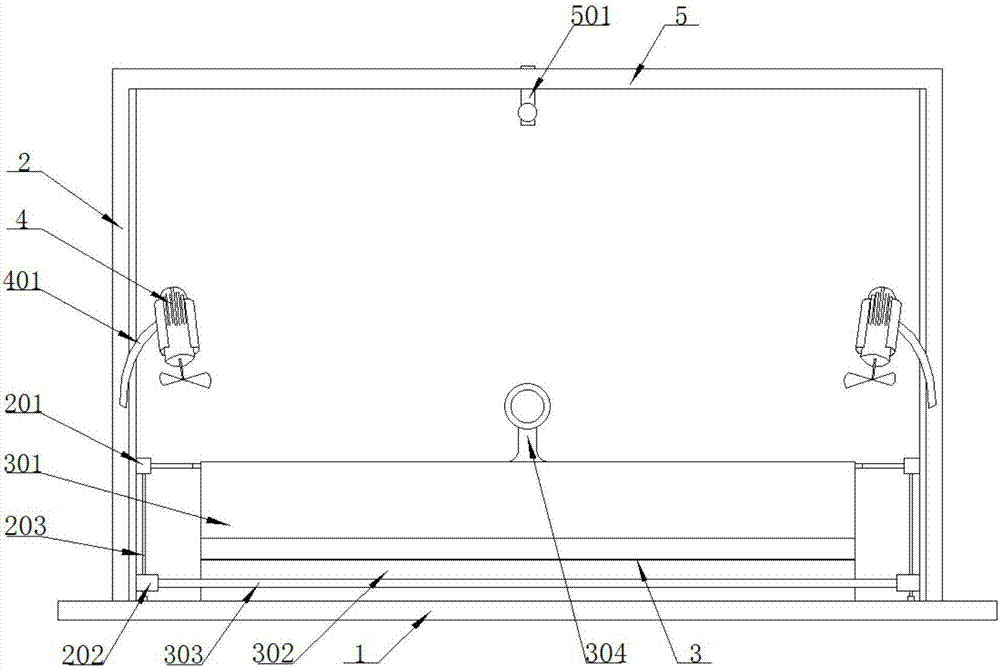

[0015] Such as figure 1 As shown, it is a manual plastic sealing machine for plastic film products, including a workbench 1, two support columns 2 are vertically arranged on the workbench 1, and each support column 2 is provided with a width along the length direction of the support column 2. Chutes, each wide chute is slidingly connected with a large slider 201, in order to ensure that the free end of the film product to be plastic-sealed is pressed on the sealing support bar 302, and at the same time it is convenient to seal the heating strip 301 to plastic-seal the film product, each wide chute Both are provided with a narrow chute along the length direction of the support column 2, a small slider 202 is slidably connected in the narrow chute, the sealing pressure plate 303 is connected with the corresponding small slider 202, and a sealing pressure part is arranged between the two support columns 2 3. The sealing and pressing part 3 includes a sealing heating strip 301 con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com