Individualized sternum prosthesis with computer-aided design and manufacturing method

A computer-aided and manufacturing method technology, applied in prosthetics, bone implants, medical science, etc., can solve problems such as limited range of motion of the upper limbs, achieve the effects of reducing radiation exposure time, reasonable design, and reduced surgical trauma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

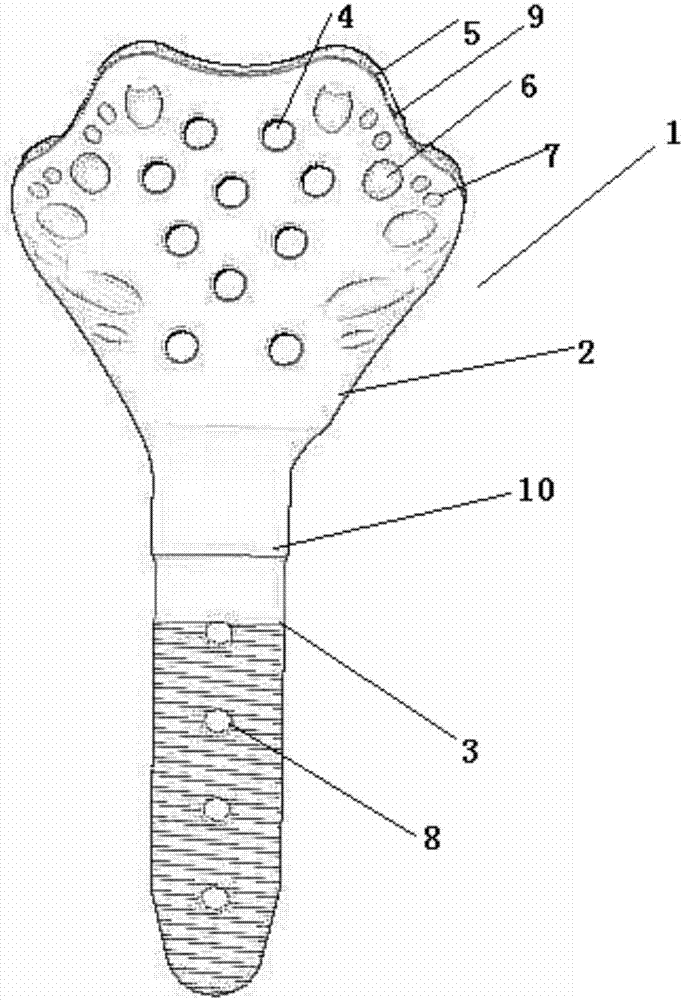

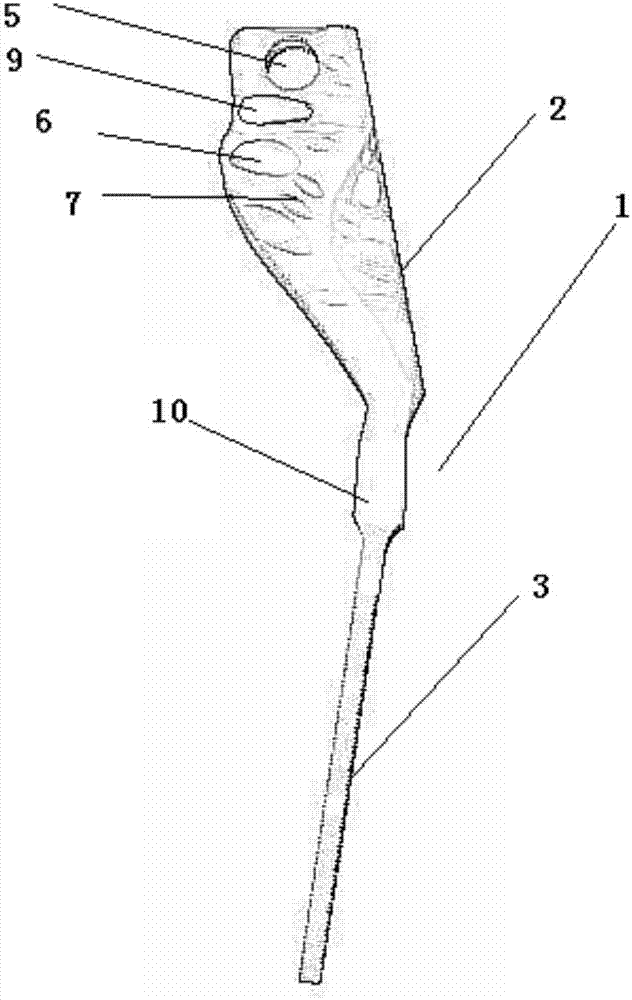

[0058] This embodiment is a computer-aided design method for making an individualized sternal prosthesis 1 applied to cases of sternal cartilage tumors.

[0059] 1. Using mimics software and CT data to reconstruct the three-dimensional model of the patient's chest, including the clavicle, the first rib to the fifth rib, the sternal manubrium and the sternal body model;

[0060] 2. Measure parameters such as cartilage tumor resection range, sternal length, clavicle distance, first inter-rib distance, second inter-rib distance, sternal cavity volume, etc. Measurement parameters can be increased according to actual needs.

[0061] 3. Use the modeling software to design the shape of the sternal prosthesis 1 with reference to the shape of the manubrium sternum; because the distance between the clavicles is 40.5 mm, the top length of the sternal prosthesis 1 is 36.0 mm, and the distance between the sternal prosthesis 1 and the clavicles on both sides is 36.0 mm. A gap of 2.25mm is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com