Handle type high torque external driving power unit

A power device and high-torque technology, applied in electromechanical devices, connected with control/drive circuits, electric components, etc., can solve problems such as large footprint, complicated maintenance, and power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

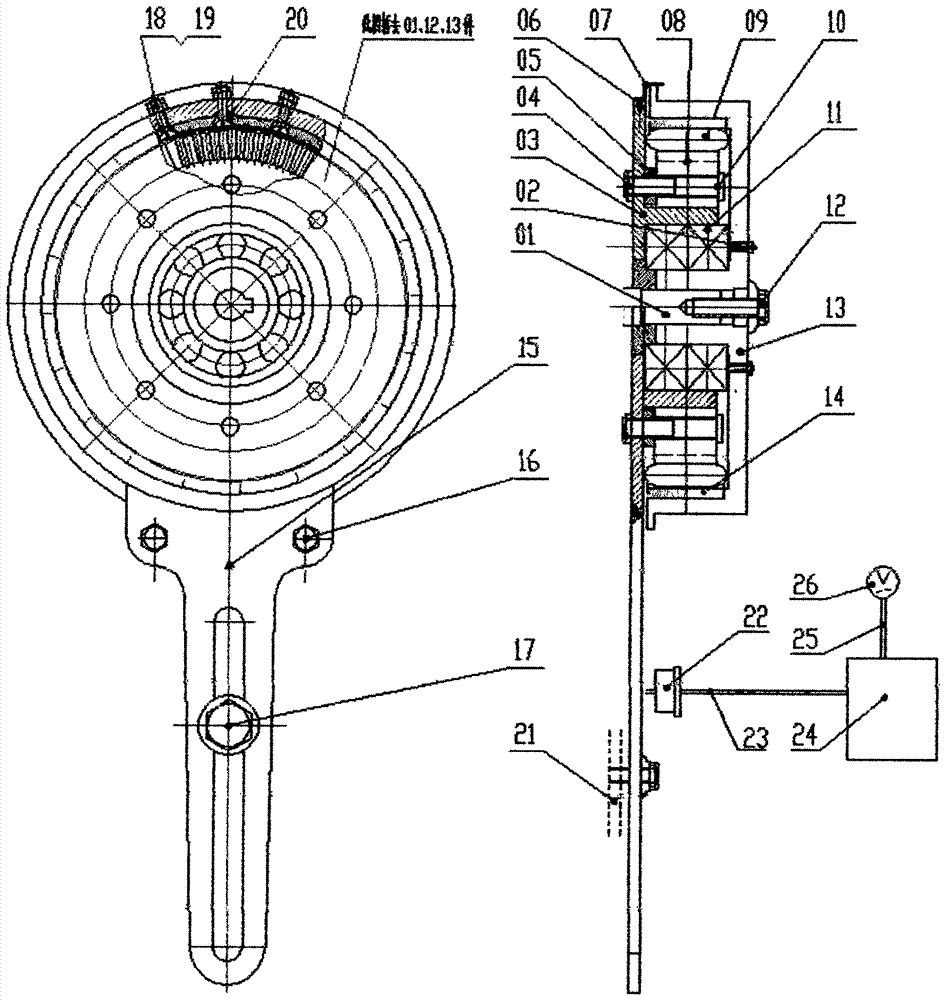

[0015] Firstly, the fixed winding (9) is embedded in the fixed stator slot (8), the notch of the fixed stator slot (8) faces outward, and the fixed flat washer nut (5) and fixed flat nut are added with the fixed shaft pin (10) (4) Connect it to the fixed front end cover (3), weld the fixed front end cover (3) to the torque adjustment handle (15) and fix it on the driven drive equipment housing (21) with the torque adjustment bolt (17) , the torque adjustment handle (15) and the fixed front end cover (3) are used to fix the connecting bolt (16) with a torque, and the inner surface of the rotating cylinder liner (13) is rotated with a magnetic steel bead (20) to rotate the magnetic steel (14) with a nut (18 ) and the countersunk screw (19), the outer surface of the shaft hole of the rotating cylinder sleeve (13) is equipped with a bearing (11), and the inner surface of the shaft hole of the rotating cylinder sleeve (13) is sleeved on the high-speed shaft (1) of the driving equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com