A kind of porous rock sample production mold and production method

A rock sample and pore technology, applied in the field of rock-like samples and their preparation, can solve the problems of the permeability research of rock samples that cannot reserve pores, the influence of the original mechanical characteristics of rock samples, and the single shape of pores and cracks, etc., to achieve The effect of short order cycle, low cost and great flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

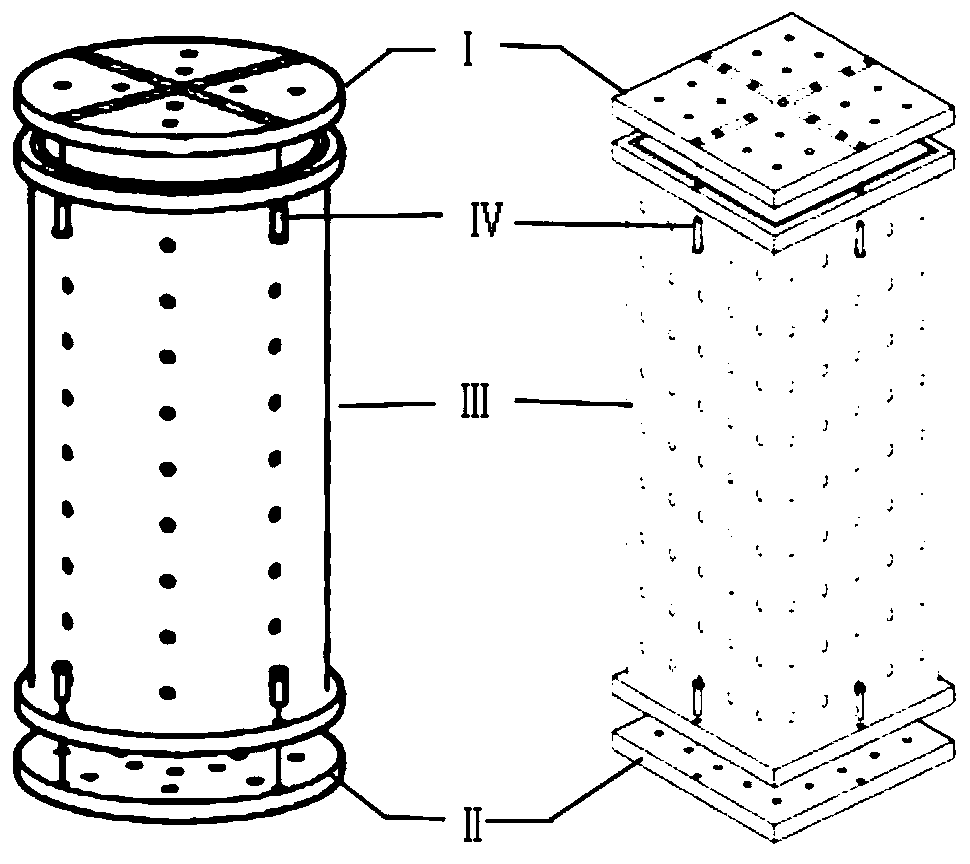

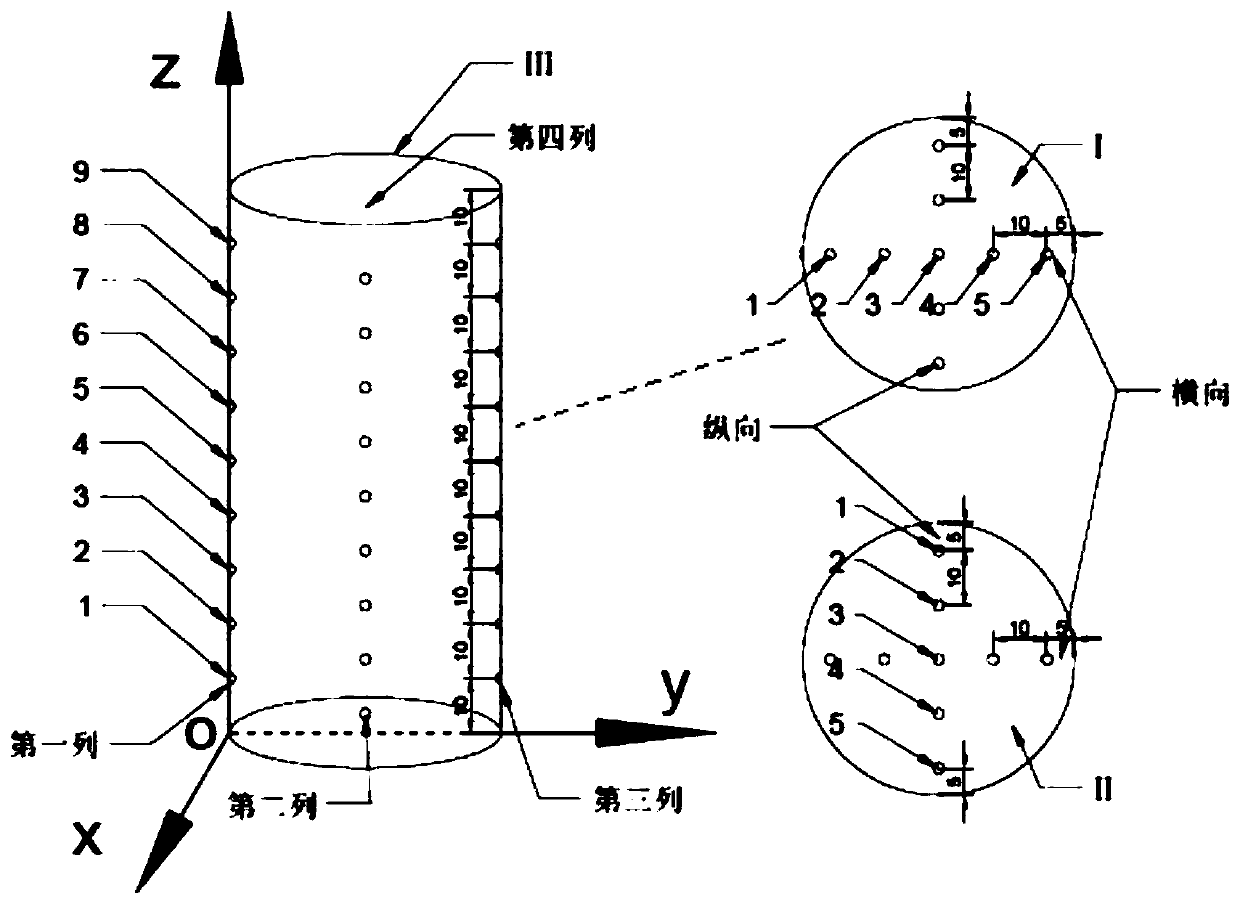

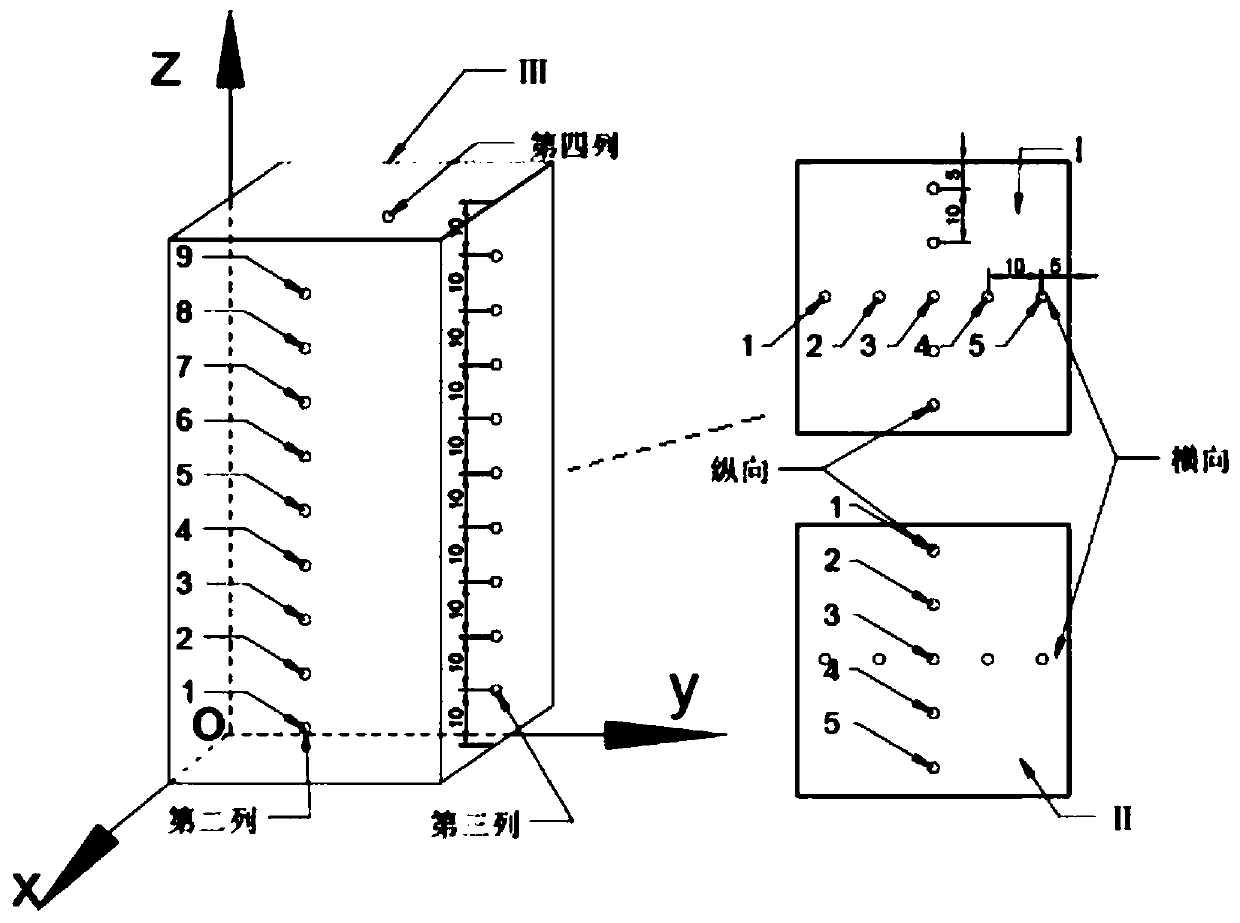

[0030] In this embodiment, taking the standard rock sample as an example, respectively design cuboid and cylinder molds, and take the hole coordinates of their special points for detailed description, such as figure 1 As shown, its main structure includes three parts: movable upper base plate I, lower base plate II and mold body III. Bolt holes are evenly distributed around the upper and lower ports of the movable upper base plate I, lower base plate II and mold body III along the circumferential direction. , the movable upper bottom plate Ⅰ, lower bottom plate Ⅱ and mold body Ⅲ are connected and fixed with each other through bolts Ⅳ anchored in cooperation with the bolt holes, which is convenient for demoulding of prefabricated samples; the size of the cuboid mold is 50mm× 50mm×100mm, the size of the cylindrical mold is Φ50mm×100mm; the upper bottom plate I, the lower bottom plate II and the mold body III are respectively provided with holes evenly arranged at equal intervals,...

Embodiment 2

[0049] In this embodiment, the square sample mold described in Example 1 is used to prepare a porous rock sample, and the specific preparation process includes the following steps:

[0050] (1) Hole positioning: select two points in Example 1, calculate the pore length to be 78.1mm, and the angle with the Z axis to be 50.1°;

[0051] (2) Tin foil patch fixation: After determining the coordinates of the hole, paste the tin foil patch on the upper and lower bottom plates and the inner wall of the mold to prevent the pouring slurry from overflowing from the hole;

[0052] (3) Iron wire placement: Select a 2mm diameter straight iron wire according to the required pore shape, apply paraffin evenly on the surface of the iron wire and check the uniformity, then extend the two ends of the iron wire through the tin foil patch to the outside of the positioning hole, and use the iron wire clamp to fix the iron wire to locate;

[0053] (4) Sample pouring: After the iron wire positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com