Foam concrete foaming agent and preparation method thereof

A foamed concrete and foaming agent technology, which is applied in the field of civil engineering, can solve the problem that the composite foaming agent does not significantly improve the foaming power and stability of the composite components, and the protein foaming agent has good stability and foaming. The problem of low foaming force and foam stability can achieve the effect of promoting economical transformation, less impact on environmental pollution, and high foaming power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

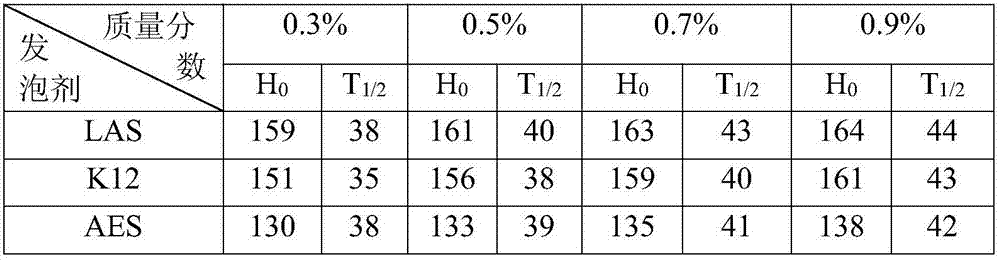

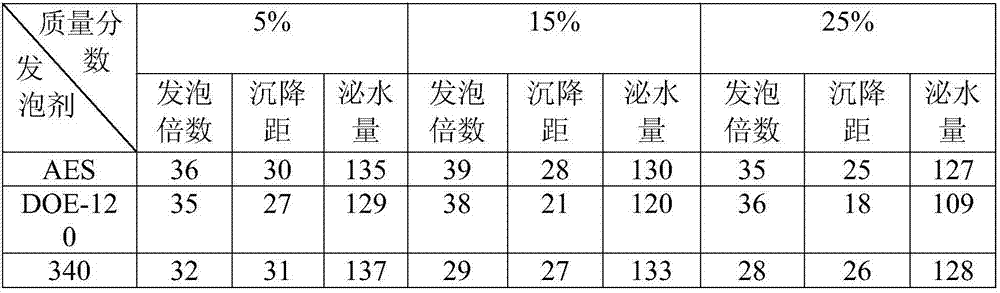

[0055] A foam concrete foaming agent, comprising 0.7% sodium dodecylbenzenesulfonate (LAS) and 0.18% methyl glucoside polyoxyethylene ether dioleate (DOE-120) in mass fraction , the mass fraction is 0.02% of hydroxyethyl cellulose (HEC) and the mass fraction of 0.03% of polypropylene cross-linked resin (Carbomer340), and the mass ratio of the four is 1:1:1:1.

[0056] The preparation method of the foamed concrete foaming agent comprises the steps of: respectively taking mass fraction of 0.7% sodium dodecylbenzene sulfonate (LAS), and mass fraction of 0.18% methyl glucoside polyoxyethylene ether dioleic acid Grease (DOE-120), hydroxyethyl cellulose (HEC) with a mass fraction of 0.02% and polypropylene cross-linked resin (Carbomer340) with a mass fraction of 0.03%, the four are mixed in a mass ratio of 1:1:1:1 , and stir evenly to prepare foam concrete foaming agent; the foam concrete foaming agent is tested, and the bubbles formed by the foaming agent are fine and rich and inde...

Embodiment 2

[0061] A foam concrete foaming agent, comprising 0.3% sodium lauryl sulfate (K12) and 0.13% methyl glucoside polyoxyethylene ether dioleate (DOE-120) in mass fraction, mass The mass ratio of 0.01% hydroxyethyl cellulose (HEC) and 0.02% polypropylene crosslinking resin (Carbomer340) is 1:1:1:1.

[0062] The preparation method of this foam concrete foaming agent comprises the following steps: taking mass fraction respectively is 0.3% sodium lauryl sulfate (K12), and mass fraction is 0.13% methyl glucoside polyoxyethylene ether dioleate ( DOE-120), the mass fraction is 0.01% hydroxyethyl cellulose (HEC) and the mass fraction is 0.02% polypropylene cross-linked resin (Carbomer340), the four are mixed in a mass ratio of 1:1:1:1, and Stir evenly to prepare a foamed concrete foaming agent; the foamed concrete foaming agent is tested and found that the bubbles formed by the foaming agent are fine and rich, independent and disconnected, the foaming multiple is 35, the settlement distan...

Embodiment 3

[0064] A kind of foam concrete blowing agent, comprising the fatty acid polyoxyethylene ether sodium sulfate that mass fraction is 0.9%, the methyl glucoside polyoxyethylene ether dioleate (DOE-120) that mass fraction is 0.21%, mass fraction is The mass ratio of 0.04% hydroxyethyl cellulose (HEC) and 0.05% polypropylene cross-linked resin (Carbomer340) is 1:1:1:1.

[0065] The preparation method of this foam concrete foaming agent comprises the following steps: taking mass fraction respectively as 0.9% fatty acid polyoxyethylene ether sodium sulfate, and mass fraction as 0.21% methyl glucoside polyoxyethylene ether dioleate (DOE- 120), the mass fraction is 0.04% hydroxyethyl cellulose (HEC) and the mass fraction is 0.05% polypropylene cross-linked resin (Carbomer340), the four are mixed in a mass ratio of 1:1:1:1, and stirred evenly , to prepare a foam concrete foaming agent; the foam concrete foaming agent is tested, and the bubbles formed by the foaming agent are fine and ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com