Rolling piece, light guide component, and method for manufacturing light guide component

A technology of light guide components and rolling pieces, which is applied in the directions of light guide, optics, optical components, etc., can solve the problems of high cost, complicated processing process, and inaccurate positioning of processing technology, and achieves low cost, high guided light output, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

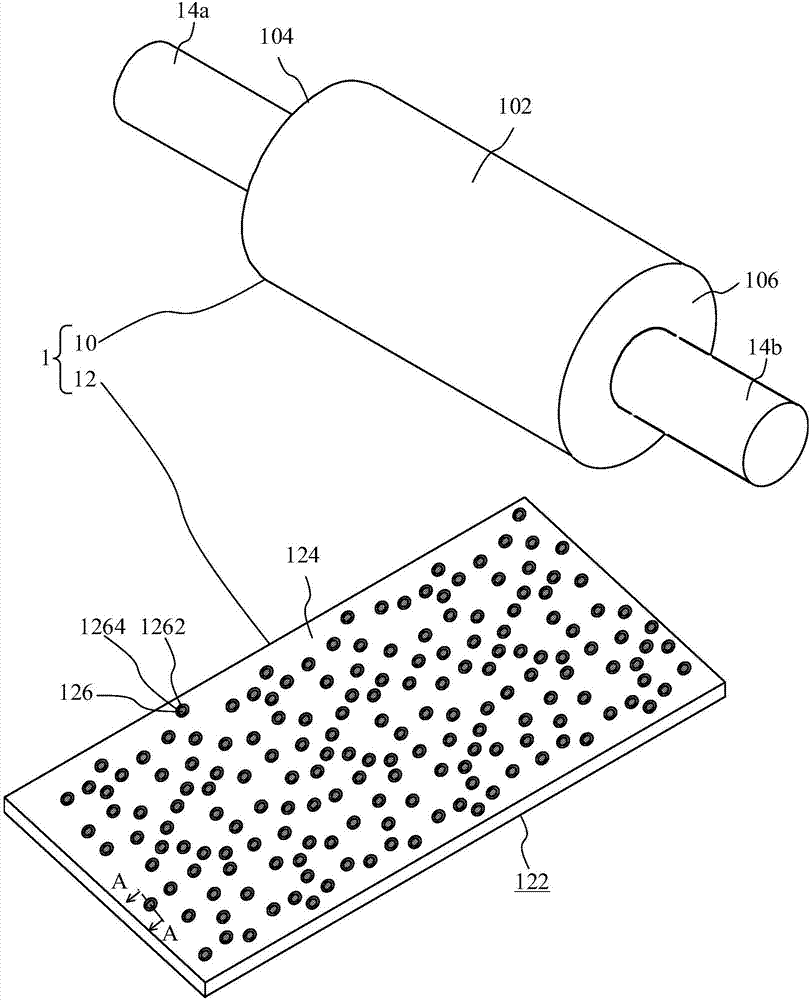

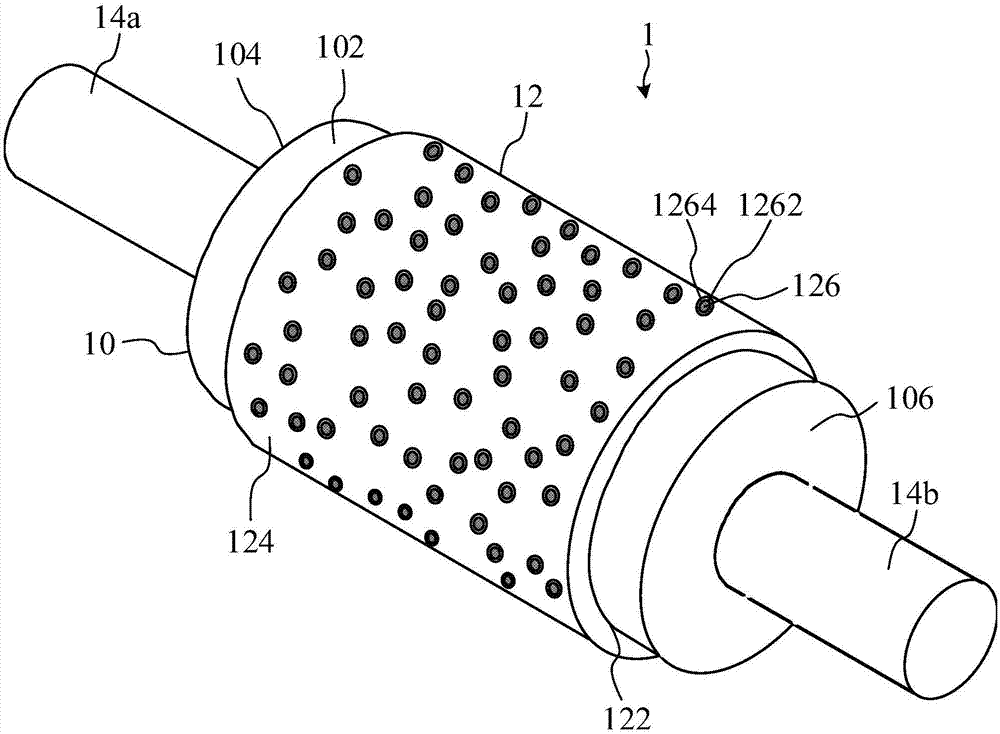

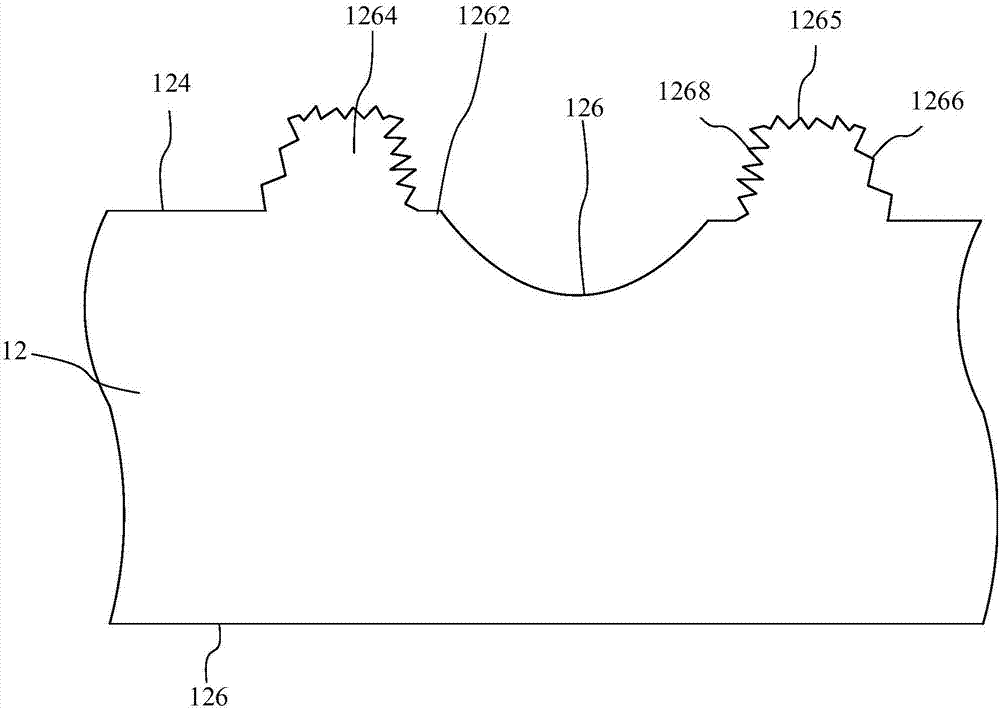

[0033] figure 1 It is an exploded appearance view of an assembly of an embodiment of the rolling part of the present invention, figure 2 for figure 1 Components of the medium rolled piece combined with the external view, image 3 for figure 1 A cross-sectional view along the line A-A of an embodiment of the metal sheet of the middle rolled piece, Figure 4 for figure 1 A cross-sectional view along the line A-A of another embodiment of the metal sheet of the intermediate rolling stock. Please also refer to Figure 1 to Figure 4 ,Such as figure 1 As shown, the rolled part 1 comprises a cylinder 10 and a metal sheet 12 . The cylinder 10 has an outer circumferential surface 102 .

[0034] The sheet metal 12 has a bonding surface 122 , a working surface 124 opposite the bonding surface 122 , and at least one hole 126 formed in the working surface 124 . Each aperture 126 has an annular raised platform 1264 proximate to the edge of its own opening 1262 . The cross section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com