Simple inclined core pulling device for injection mold

An injection mold and oblique core-pulling technology, which is applied in the field of injection mold oblique extraction and demolding devices, can solve the problems of many faulty nodes, complex structure and high manufacturing cost, and achieve the effects of reducing operating failures, wide adaptability and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

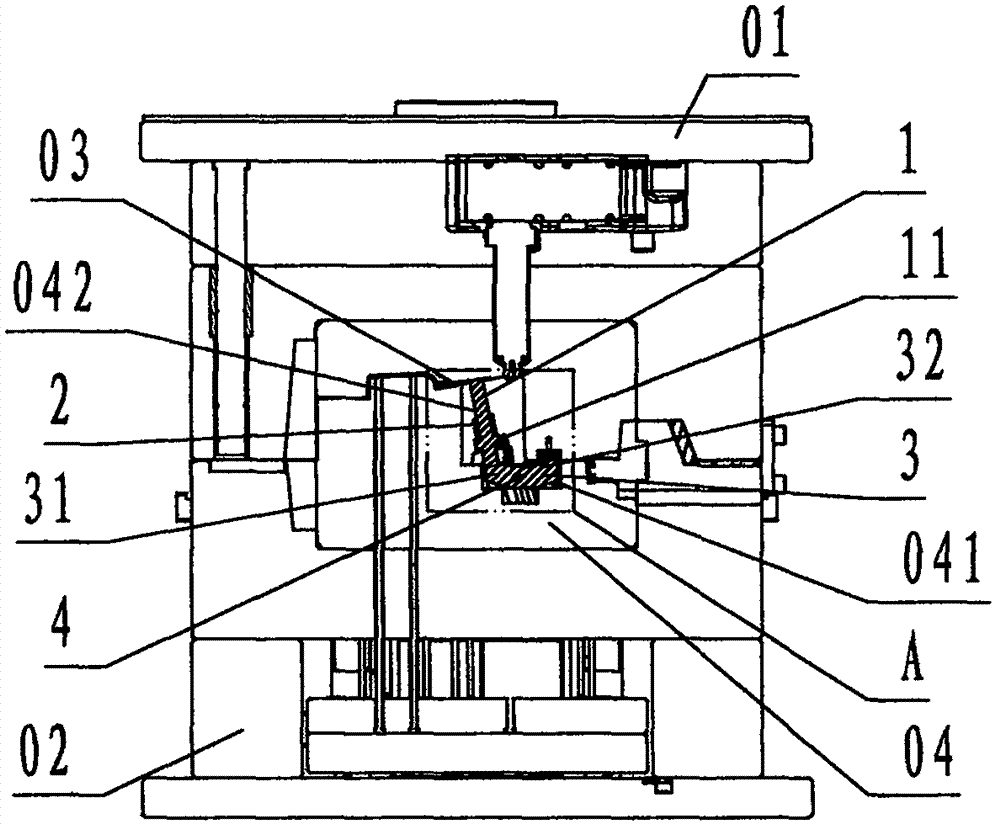

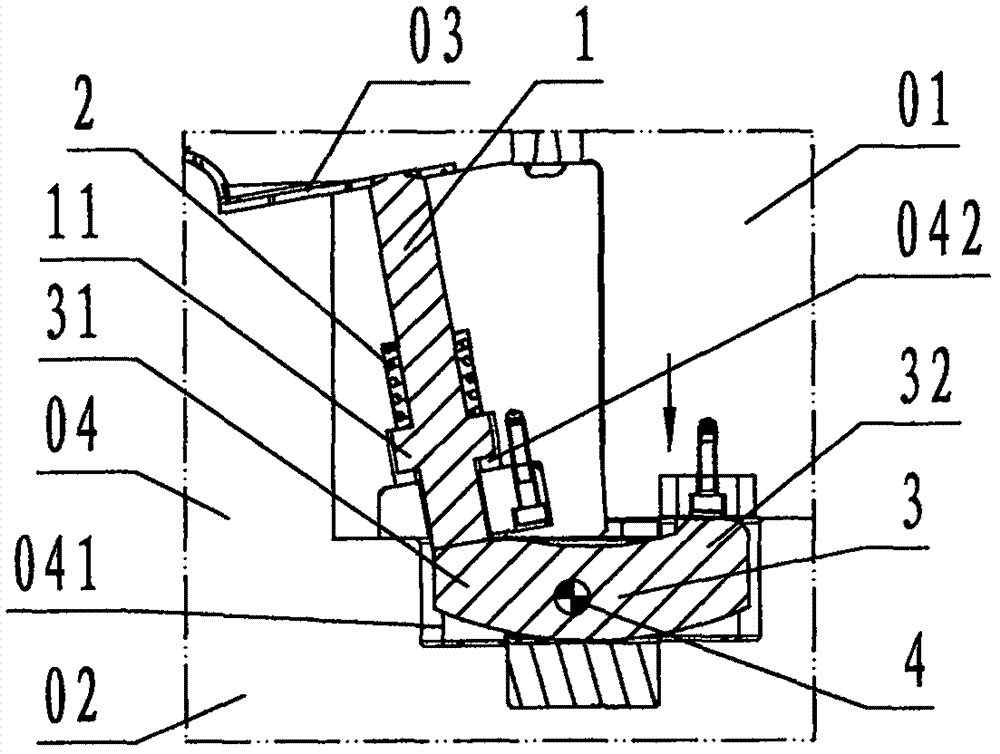

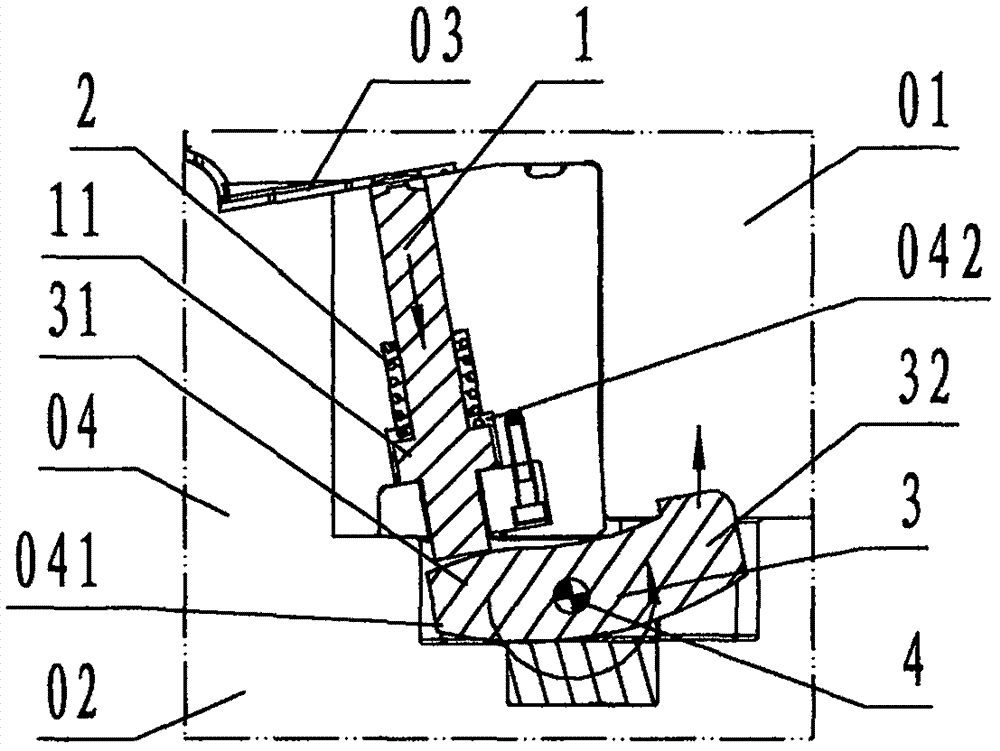

[0024] refer to Figure 1 ~ Figure 3 , a simple oblique core-pulling device for an injection mold of the present invention, comprising an oblique core-pulling 1, a spring 2, a skid 3, and a rotating shaft 4, wherein: the oblique core-pulling 1 is a cylindrical step-shaped steel member, and the oblique core-pulling The upper end of 1 is provided with the profile of the molded product 03, and the lower cylindrical surface of the oblique core-pulling 1 is provided with a flange called a stopper 11;

[0025] The spring 2 is a cylindrical helical compression spring;

[0026] The skid block 3 is a steel member with upturned left and right ends and an arc-shaped block. The middle part of the skid block 3 is provided with a circular through hole in the front and rear direction called the shaft hole, and the skid block 3 is located in the shaft hole. The left part of the shaft hole is called the resistance arm 31, and the right part of the skid block 3 located in the shaft hole is cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com