Wafer processing method

A processing method and wafer technology, applied in metal processing equipment, manufacturing tools, laser welding equipment, etc., can solve the problems of meandering cuts and inability to grow cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

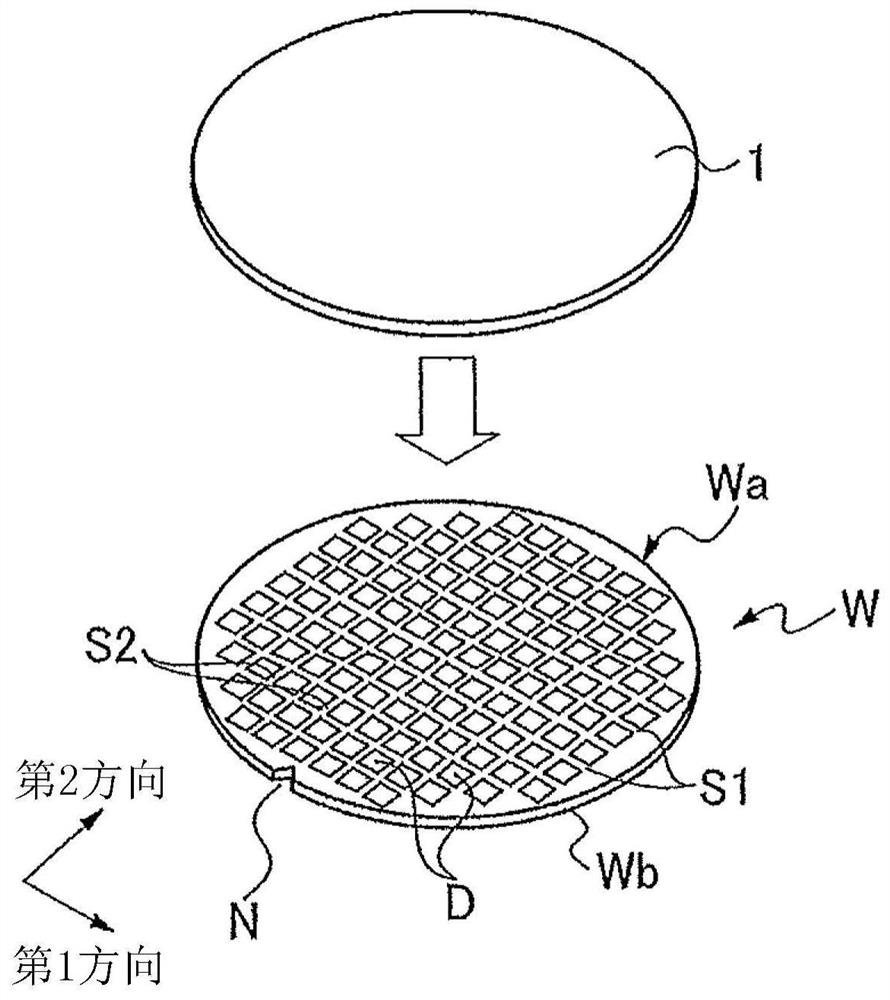

[0021] figure 1 The illustrated wafer W is an example of a workpiece having a circular plate-shaped substrate. On the front surface Wa of the wafer W, devices D are formed in a plurality of regions divided by a plurality of first planned dividing lines S1 and a plurality of second planned dividing lines S2, wherein the plurality of first planned dividing lines S1 The plurality of second planned division lines S2 extend in a second direction intersecting the plurality of first planned division lines S1 , for example, in a predetermined direction, such as a first direction. On the other hand, the surface of the wafer W opposite to the front surface Wa becomes the back surface Wb to be ground. The wafer W is, for example, a silicon wafer whose crystal orientation has an angle of 45° with respect to the extending direction of the first planned dividing line S1 and the second planned dividing line S2, and has a crystal orientation oriented at 45° with respect to the crystal orient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com