A self-cleaning evaporator

An evaporator and self-cleaning technology, which is applied in the direction of evaporator/condenser, heat transfer device cleaning, non-rotating equipment cleaning, etc., can solve the problems of affecting heat exchange effect, dust accumulation on the outer surface of pipes and cooling fins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below, the technical solution of the present invention will be described in detail through specific examples.

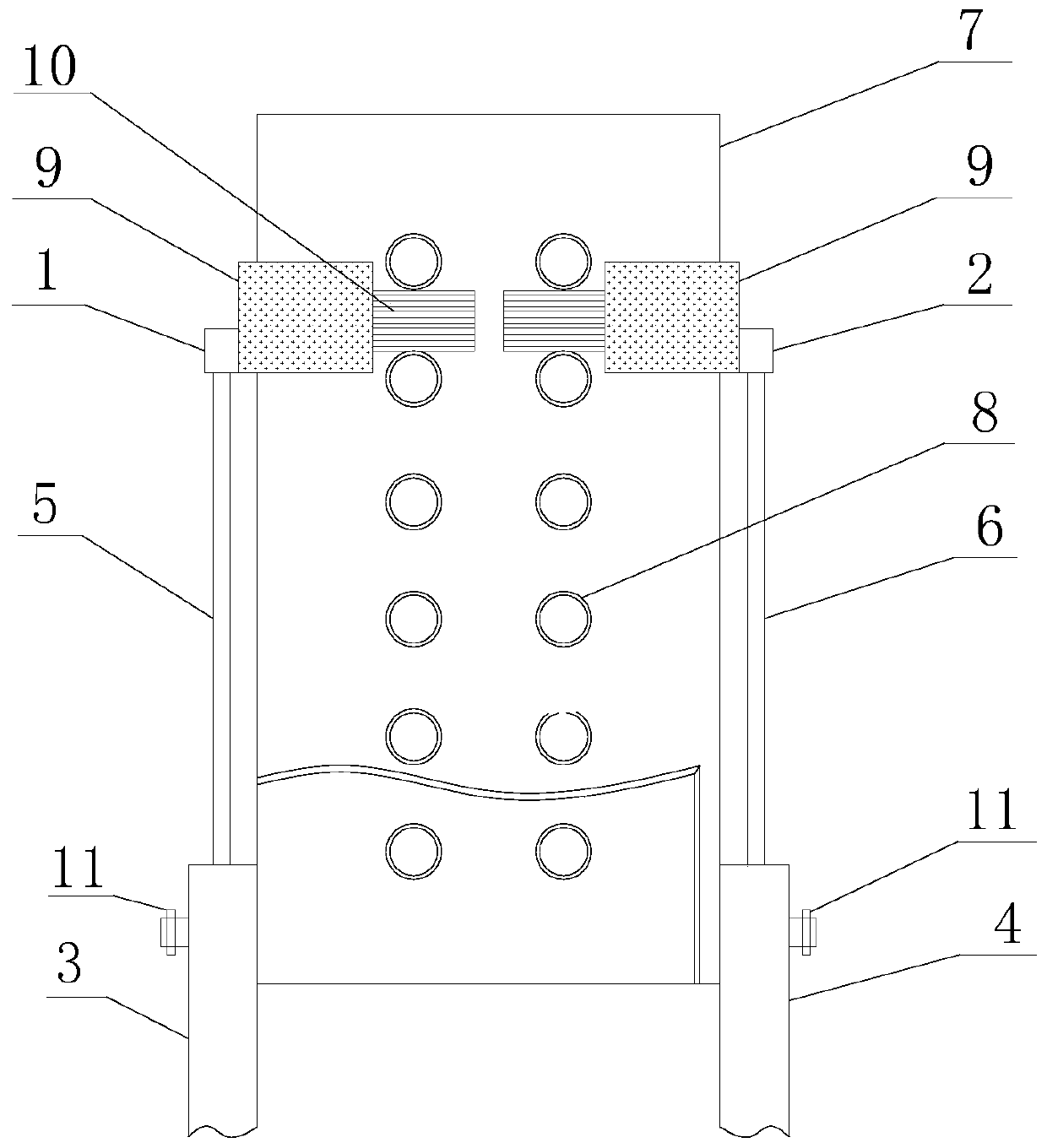

[0019] like figure 1 as shown, figure 1 It is a schematic structural diagram of a self-cleaning evaporator proposed by the present invention.

[0020] refer to figure 1 , a self-cleaning evaporator proposed by the embodiment of the present invention, including: an evaporator body, a first strip plate 1, a second strip plate 2, a first cylinder 3, a second cylinder 4, a first telescopic Rod 5, second telescopic rod 6 and proximity sensor, wherein:

[0021] The evaporator body includes radiating fins 7 arranged in layers and row pipes 8 passing through and fixed to each layer of radiating fins 7 . The row pipes 8 have inlets and outlets. The first strip plate 1 and the second strip plate 2 are relatively arranged on both sides of the evaporator body, and the extension direction of the first strip plate 1 and the second strip plate 2 is in line with the layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com