Self-adapting three-foot parallel type TBM support with three-foot parallel supporting legs

A technology of support legs and supporters, which is applied in mining equipment, earth-moving drilling, tunnels, etc., can solve the problems of failure to provide the reconstruction function of support legs, uneven contact force, unsuitable for hexapod thrusters, etc., and achieves improvement. Dynamic support force response characteristics, uniform distribution of contact loads, and effect of reducing the risk of support failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

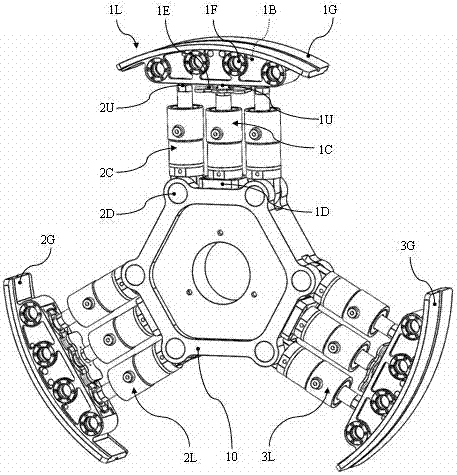

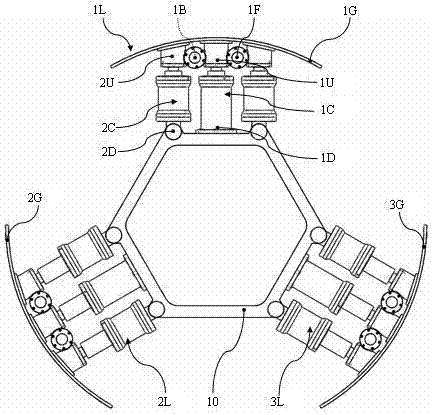

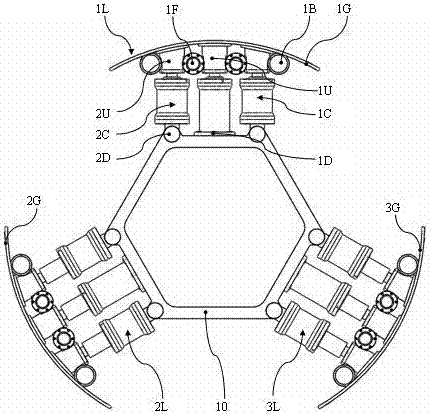

[0036] In this embodiment, an adaptive three-legged parallel TBM supporter with three-legged parallel support legs is as follows: Figure 1 ~ Figure 3 shown.

[0037] The supporter in this embodiment includes a central support 10, an upper support leg 1L, a left lower support leg 2L and a right lower support leg 3L.

[0038] The central support 10 in this embodiment is a hexagonal ring structure, and the upper support leg 1L, the lower left support leg 2L and the lower right support leg 3L are respectively vertically installed on the rings of the hexagonal ring structure forming 120° to each other. On the side, it is on the same plane as the hexagonal ring structure; the upper support leg 1L is composed of a central support cylinder 1C, two side support cylinders 2C connected in parallel and then connected in series with the upper support shoe 1G to drive the upper support The leg 1L can drive the upper support shoe 1G to move radially; the left lower support leg 2L and the r...

Embodiment 2

[0050] This embodiment is a tunneling device with a hexapod parallel thruster, and the device adopts figure 2 The structure of the support shown.

[0051] In this embodiment, a tunneling device with a hexapod parallel propeller is a hybrid tunneling device composed of a cutter head system 1, a support ring 2, a propeller 3, and a supporter 4 connected in series; the supporter 4 is as follows: figure 2 The support structure. The propulsion cylinder 3C is connected with the supporting ring 2 by the propeller front joint 3F, and the propulsion cylinder 3C and the supporter 4 are connected by the propulsion cylinder rear joint 3B, and its position is located at the supporter front joint connection seat 4F of the supporter 4 .

Embodiment 3

[0053] This embodiment is a tunneling device in which double hexapod parallel propellers are connected in series, such as Figure 5 shown.

[0054] In this embodiment, a double-hexapod parallel thruster excavation device is connected in series, which is composed of a cutter head system 1, a support ring 2, a thruster 3, a supporter 4, an auxiliary propeller 5, and an auxiliary supporter 6 in series, and the mixed connection is formed. excavation device.

[0055] The propulsion cylinder 3C of the device in this embodiment is connected with the supporter 4 by the rear joint 3B of the propulsion cylinder, and its position is located at the supporting front joint connection seat 4F of the supporter 4; the auxiliary propulsion cylinder 5C and the supporter 4 are connected by the front joint 5F of the auxiliary propulsion cylinder connection, its position is located at the rear joint connection seat 4B of the supporter 4; the auxiliary propulsion cylinder 5C and the auxiliary suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com