Washing control method of washing machine and washing machine

A control method and washing machine technology, applied in the control device of washing machine, other washing machines, washing devices, etc., can solve the problem of not fully improving the washing efficiency of inclined washing machines, and achieve the effects of optimized coordination, optimized energy saving, and improved energy efficiency level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

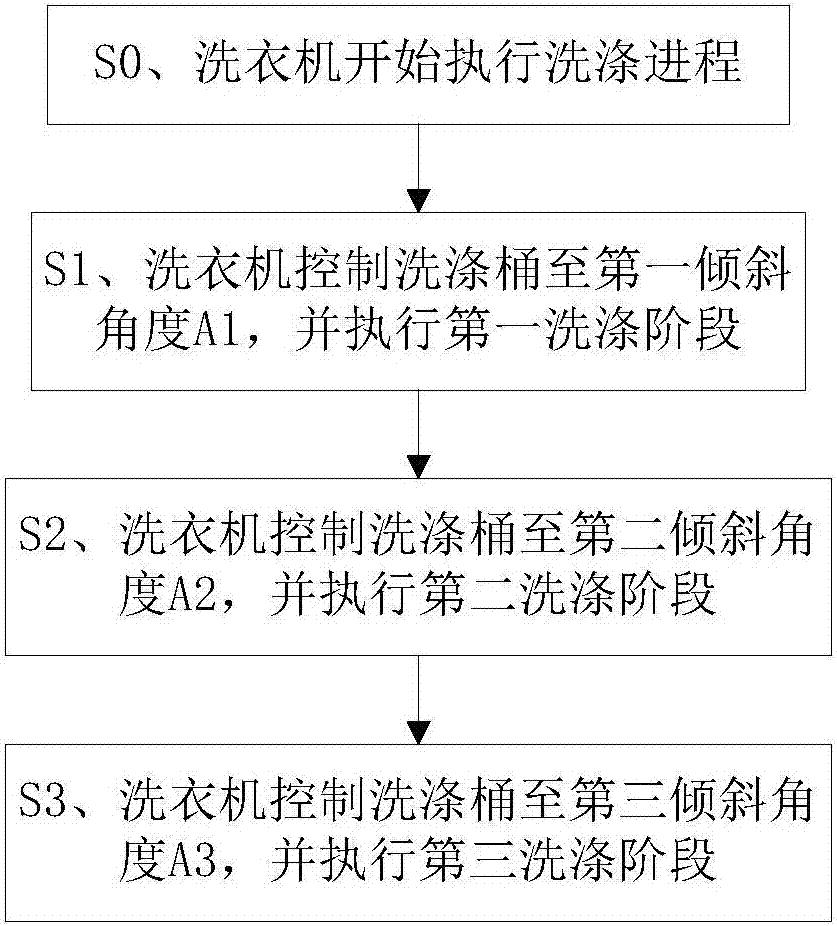

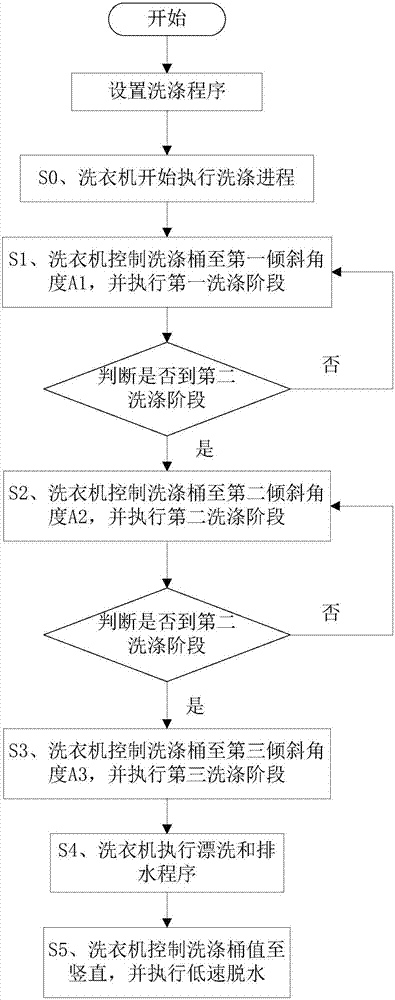

[0047] like figure 1 and figure 2As shown, a washing control method of a washing machine according to the present invention, the washing process of the washing machine is divided into at least two washing stages, and the washing buckets in each washing stage correspond to different inclination angles.

[0048] Specifically, during the washing process of the washing machine, the washing tub of the washing machine is arranged obliquely, and the inclined washing tub is used to generate complex water flows including up and down directions, thereby improving the washing effect of the washing machine. In addition, during the entire washing process of the washing machine, as the washing process advances, the clothes in the washing machine have different requirements for each washing parameter in the washing machine. In order to better improve the washing efficiency of the washing machine, at least one factor affecting the energy efficiency parameters is divided, and at the same time...

Embodiment 2

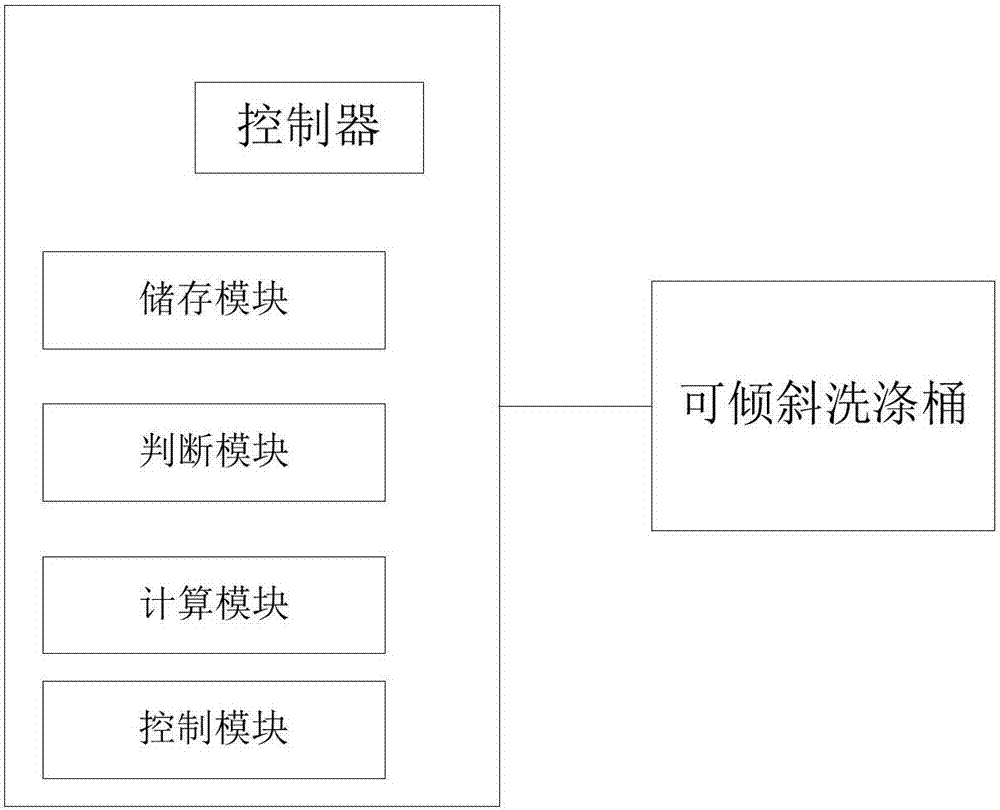

[0094] In this embodiment, the preset washing parameter factors in the washing stage are divided; and they are effectively combined with other washing parameter factors of the washing machine to form a washing stage that is more compatible with the inclination angle factor of the washing tub, and improve the washing stage. washing efficiency.

[0095] Preferably, in this embodiment, the rotation-stop timing factor in the washing stage is divided, and combined with the washing machine speed, the degree of coordination of each washing parameter in the washing stage is improved, the washing control method in the washing stage is optimized, and the washing control method is further improved. washing effect of the washing machine.

[0096] Further, the first washing stage T1 performs washing according to the set rotation speed X1 and the time sequence M1 of turning on and off;

[0097] The second washing stage T2 performs washing according to the set rotation speed X2 and the time...

Embodiment 3

[0115] like figure 2 As shown, in this embodiment, the washing control method can also be combined with the washing program, and then the control method can be divided into T washing stages according to the set washing program; Washing and slow washing and other modes to obtain the washing stage value; wherein, the washing stage value obtained when the washing program is fast washing is smaller than the washing stage value obtained when the washing program is slow washing.

[0116] Preferably, the control method is divided into T washing stages according to the washing time parameters set in the washing program, and T≥2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com