Coordination polymerization preparation method of 1, 4-poly 3-methylene cyclopentene

A technology of methylenecyclopentene and coordination polymerization is applied in the field of coordination polymerization preparation of 1,4-poly3-methylenecyclopentene, and can solve the problem of no 3-methylenecyclopentene and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

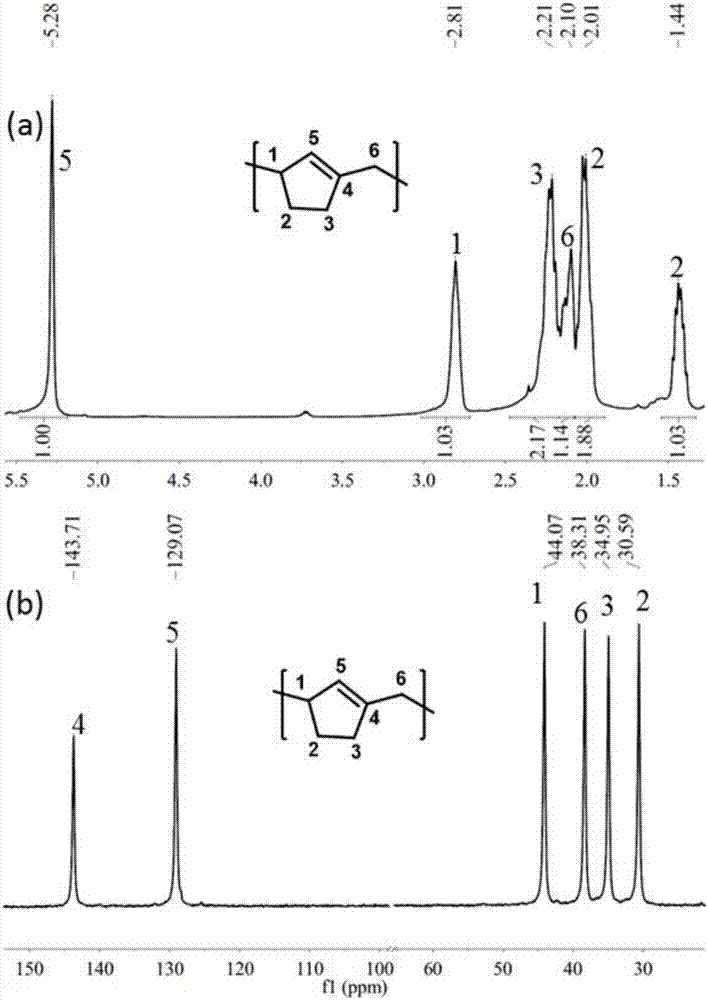

[0072] Under anhydrous and oxygen-free conditions, the rare earth compound 1 (8.8mg, 10μmol), [Ph 3 C][B(C 6 f 5 ) 4 ] (9.2mg, 10μmol) and Ai i Bu 3 (0.2mL×0.25M) in toluene solution 2mL was added to 25mL toluene solution (3mL) containing 3-methylenecyclopentene (0.16g, 2mmol) monomer at 25°C. After stirring at high speed for 1 minute, a small amount of ethanol solution was added to terminate the polymerization reaction. Then the reaction solution was poured into a small amount of 100ml methanol containing hydrochloric acid and stabilizer (BHT) for sedimentation. The obtained polymer was dried in a vacuum oven at 40° C. for 48 hours to obtain a polymer with a net weight of 0.16 g (yield 100%). The H NMR spectrum of the obtained polymer ( 1 H NMR) and carbon nuclear magnetic spectrum ( 13 C NMR) such as figure 1 As shown, it can be known that 1,4-poly-3-methylenecyclopentene was successfully prepared.

Embodiment 2~47

[0073] Examples 2-47: The experimental procedure of this series of examples is the same as that of Example 1, and the polymerization reaction conditions and the change conditions of the catalytic system are described in Table 1 in detail.

[0074] Table 1. Preparation of 1,4-poly-3-methylenecyclopentene by coordination polymerization

[0075]

[0076]

[0077] D in Table 1 represents organoboron salt [Ph 3 C][B(C 6 f 5 ) 4 ], E represents organoboron salt [NEt 3 H][B(C 6 f 5 ) 4 ], F stands for organoboron salt [PhNMe 2 H][B(C 6 f 5 ) 4 ].

[0078] The types and proportions of the rare earth compounds, organoboron salts and alkylaluminum compounds, and the solvents used in the above examples can be any combination defined in the above technical solutions, and will not be listed here.

[0079] From the polymerization data of Examples 1-47, it can be concluded that when the catalyst solution provided by the present invention catalyzes the polymerization reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com