A self-reinforced ring-shaped anti-collision vehicle winch based on motor control

A motor-controlled, reinforced technology, applied in vehicle parts, clockwork mechanisms, traction connectors, etc., to solve the problems that the wire rope cannot be kept vertical and released from the car, the force is unbalanced, and there is no anti-collision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

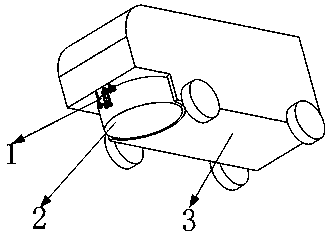

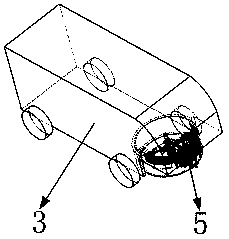

[0036] Such as figure 1 , 2 As shown, it includes an adjustment mechanism 1 and a winch mechanism 2, such as figure 1 , 2 As shown, wherein the winch mechanism 2 is installed on the lower side of the front end of the automobile 3; as figure 1 , 2 As shown, the adjustment mechanism 1 is installed on the lower side of the front end of the automobile 3, and the adjustment mechanism 1 is located on the front side of the winch mechanism 2.

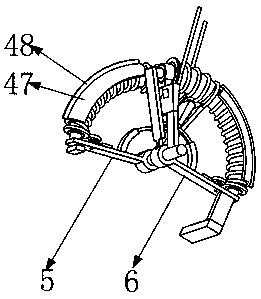

[0037] Such as image 3 As shown, the above-mentioned winch mechanism 2 includes a first winding mechanism 5, a second winding mechanism 6, a rotating shaft 16, a first limiting plate 27, a second limiting plate 28, a ring shell 26, and a second fixed shaft 30, such as image 3 As shown, wherein the ring shell 26 is installed on the lower side of the front end of the car 3; the rotating shaft 16 is located in the ring shell 26, and one end of the rotating shaft 16 is installed on the lower end face of the car 3; as image 3 As shown, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com