Planetary grinding head with oil leakage prevention mechanism

A planetary, oil-leakage-proof technology, applied in the direction of grinding heads, manufacturing tools, grinding/polishing equipment, etc., can solve the problems of oil leakage, easy damage, thinning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations.

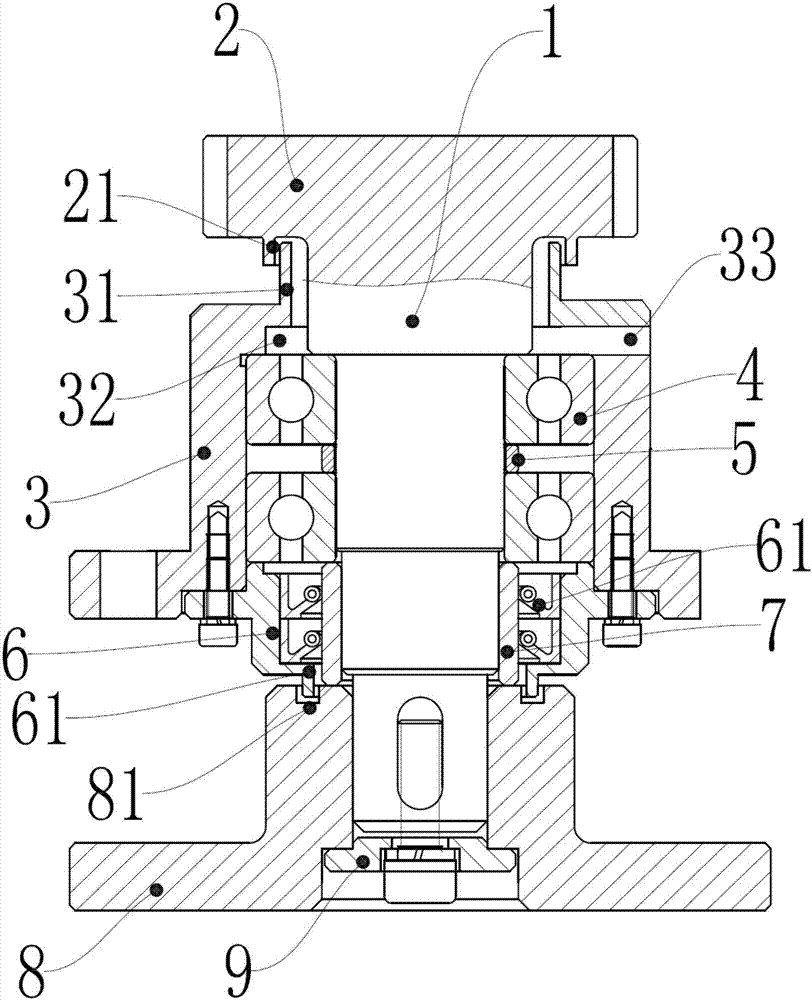

[0028] The planetary grinding head with oil leakage prevention mechanism of this embodiment, such as figure 1 As shown, it includes a planetary gear shaft 1 and a bearing seat 3, the bearing seat 3 is sleeved with the planetary gear shaft 1, and a planetary gear 2 is provided on the top of the planetary gear shaft 1;

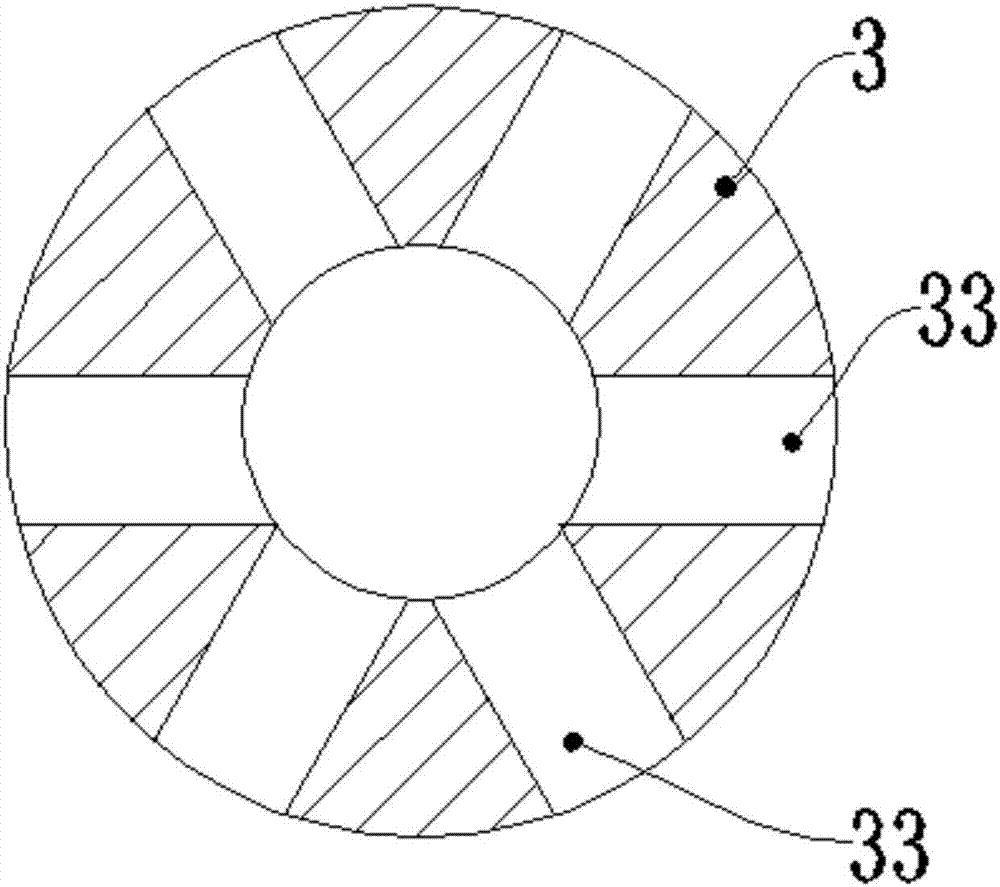

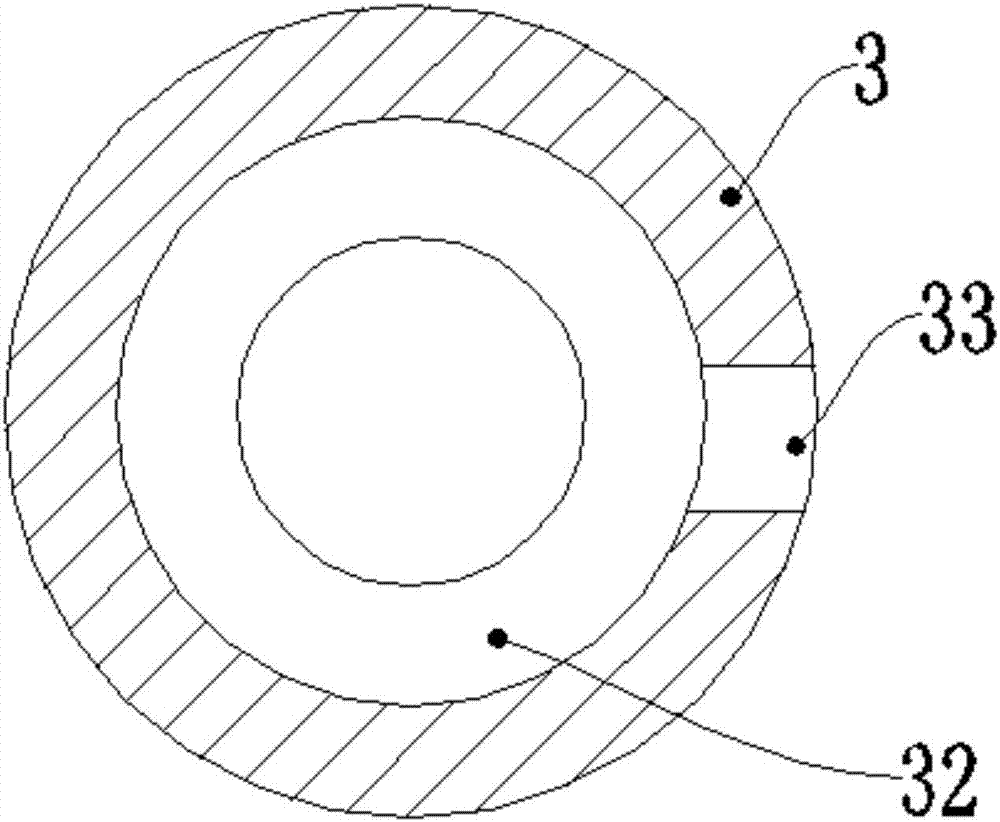

[0029] The lower end surface of the base of the planetary gear 2 is provided with a first annular groove 21, and the upper end surface of the base of the bearing seat 3 is provided with a first annular convex groove 31 that is in clearance fit with the first annular groove 21;

[0030] The bearing housing 3 is further provided with a pressure relief channel, the pressure relief channel is arranged at the bottom of the first annular convex groove 31, and the pressure relief channel communicates with the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com