Turbo fan sand washing machine

A technology of sand washing machine and turbofan, which is applied in the field of sand washing machines, can solve the problems of inability to release the carbon source of sand grains, obvious odor of sand discharge, etc., and achieve the effect of eliminating energy impact and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

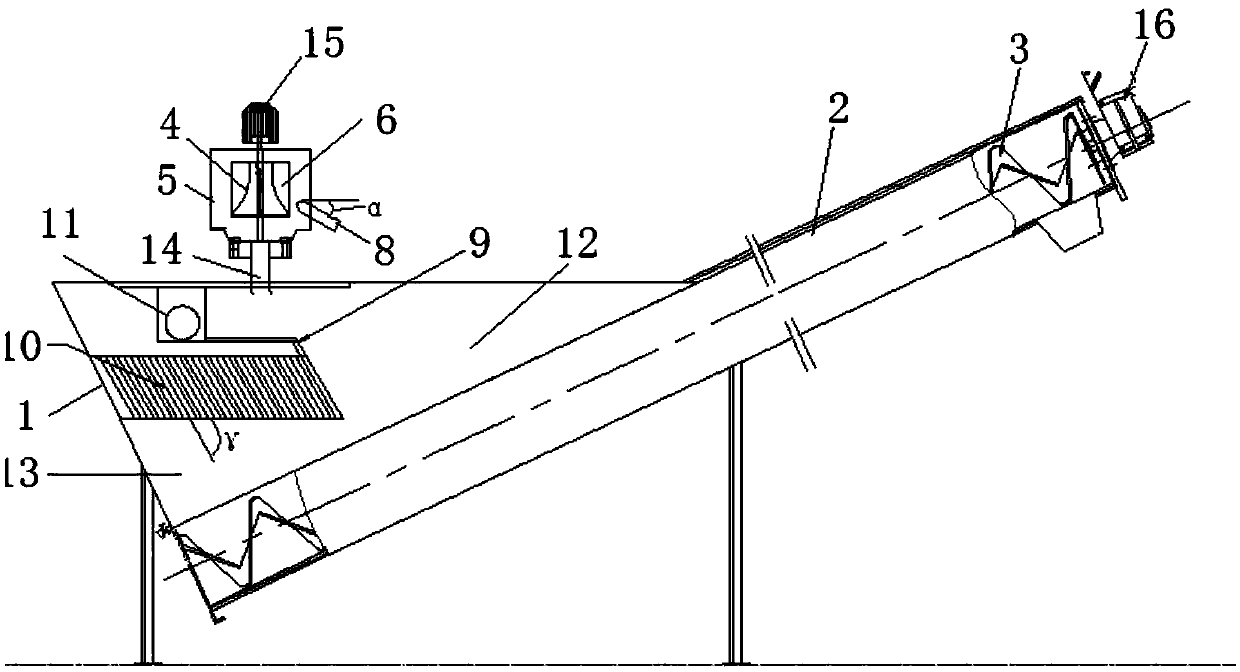

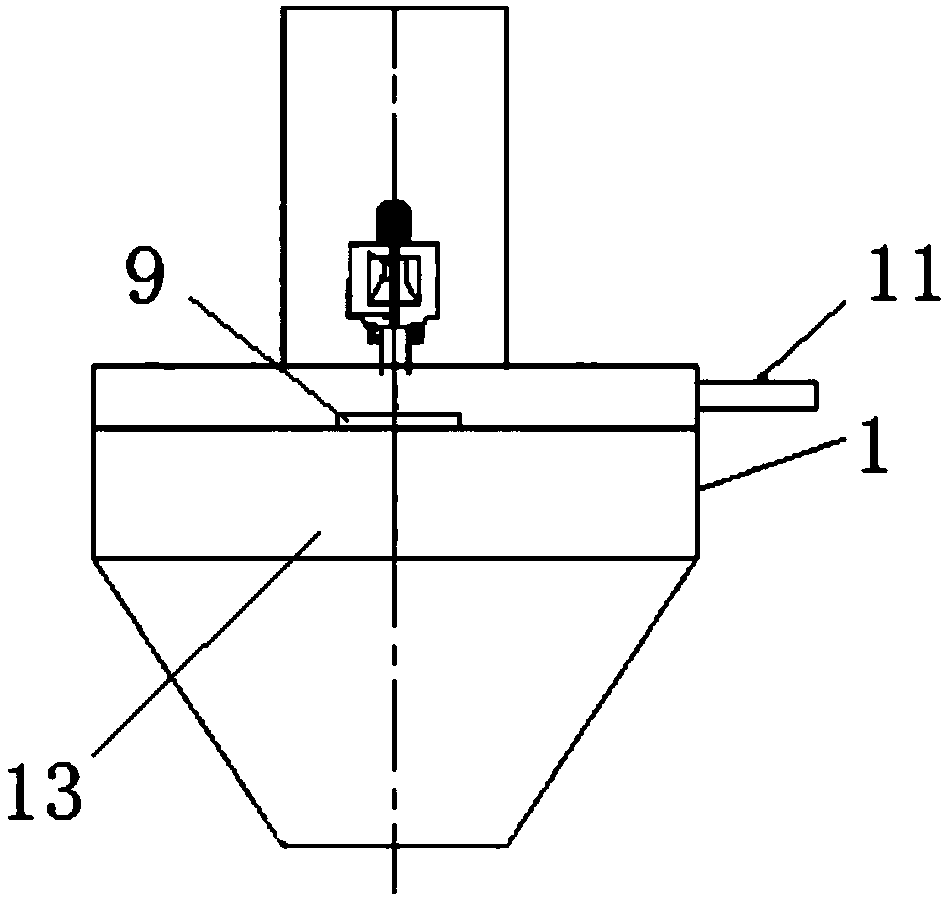

[0015] The present invention will be further described below through the embodiments and in conjunction with the accompanying drawings.

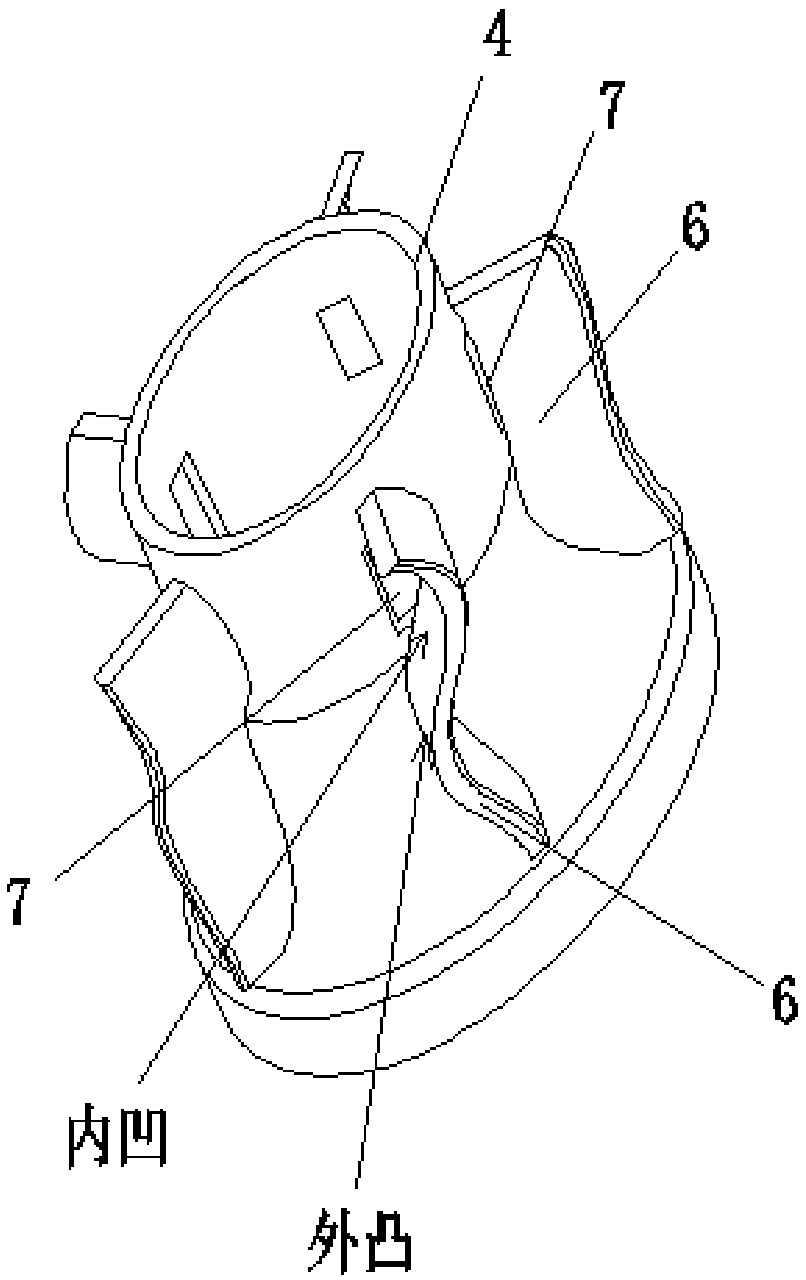

[0016] combine figure 1 — Figure 4 As shown, a turbofan sand washing machine is mainly composed of a rotating inner cylinder 4, a closed and fixed outer casing 5, and wavy paddles 6. The rotating inner cylinder 4 is located in the closed and fixed casing 5 , and bearings are installed in the closed and fixed casing 5 for realizing the relative rotation of the rotating inner cylinder 4 . The space inside the rotating inner cylinder 4 is the inner chamber, and the space between the rotating inner cylinder 4 and the closed and fixed shell 5 is the outer chamber.

[0017] The rotating inner cylinder 4 has a trumpet-shaped base. On the outer wall of the rotating inner cylinder 4, there are fixed a number of wavy paddles 6 distributed in a divergent shape. distributed.

[0018] There is a distance between the wave-shaped paddle 6 and the clo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com