A granary uniform temperature control temperature cooling system

A heat dissipation system and granary technology, applied to agricultural machinery and tools, gardening, botany equipment and methods, etc., can solve the problems of heat dissipation efficiency and cooling effect, etc. good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

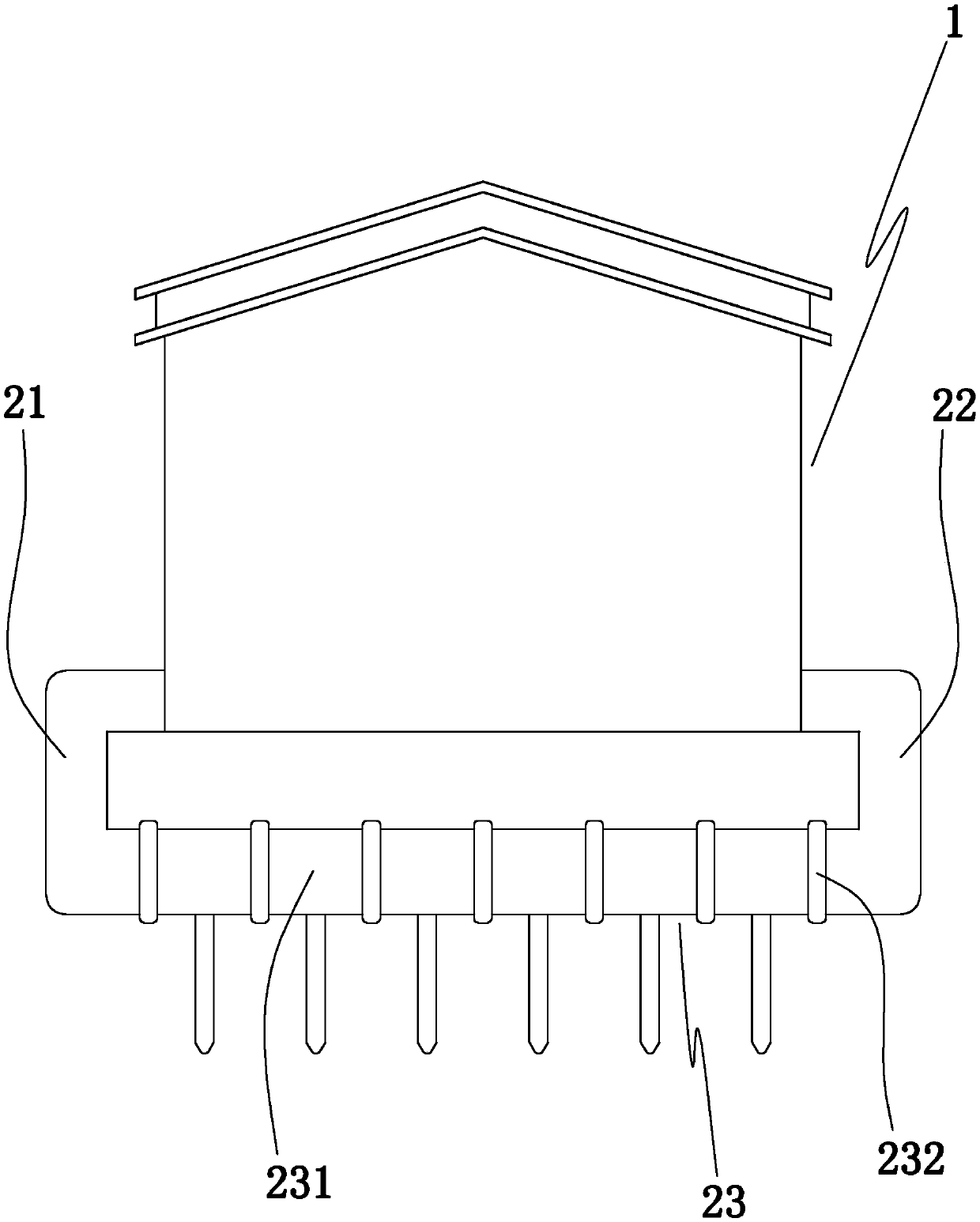

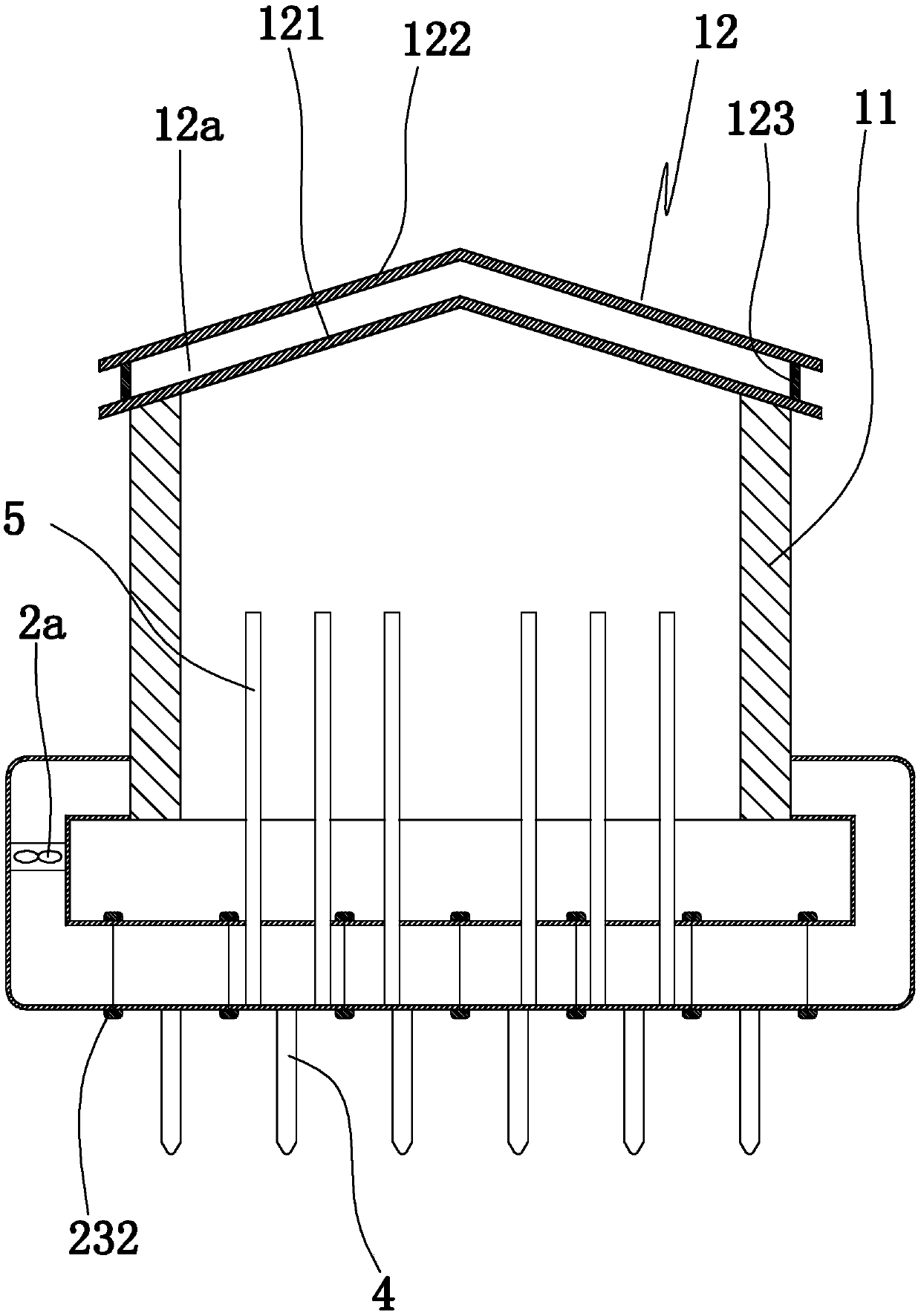

[0033] Embodiment 1: as Figure 1 to Figure 6 As shown in , a granary uniform temperature control temperature cooling system includes a granary storage bin body 1, the granary storage bin body includes two long side walls 11 arranged in parallel, two short side walls arranged in parallel and a warehouse roof 12, and two gas storage bins. Air conditioning duct structure and an external air duct;

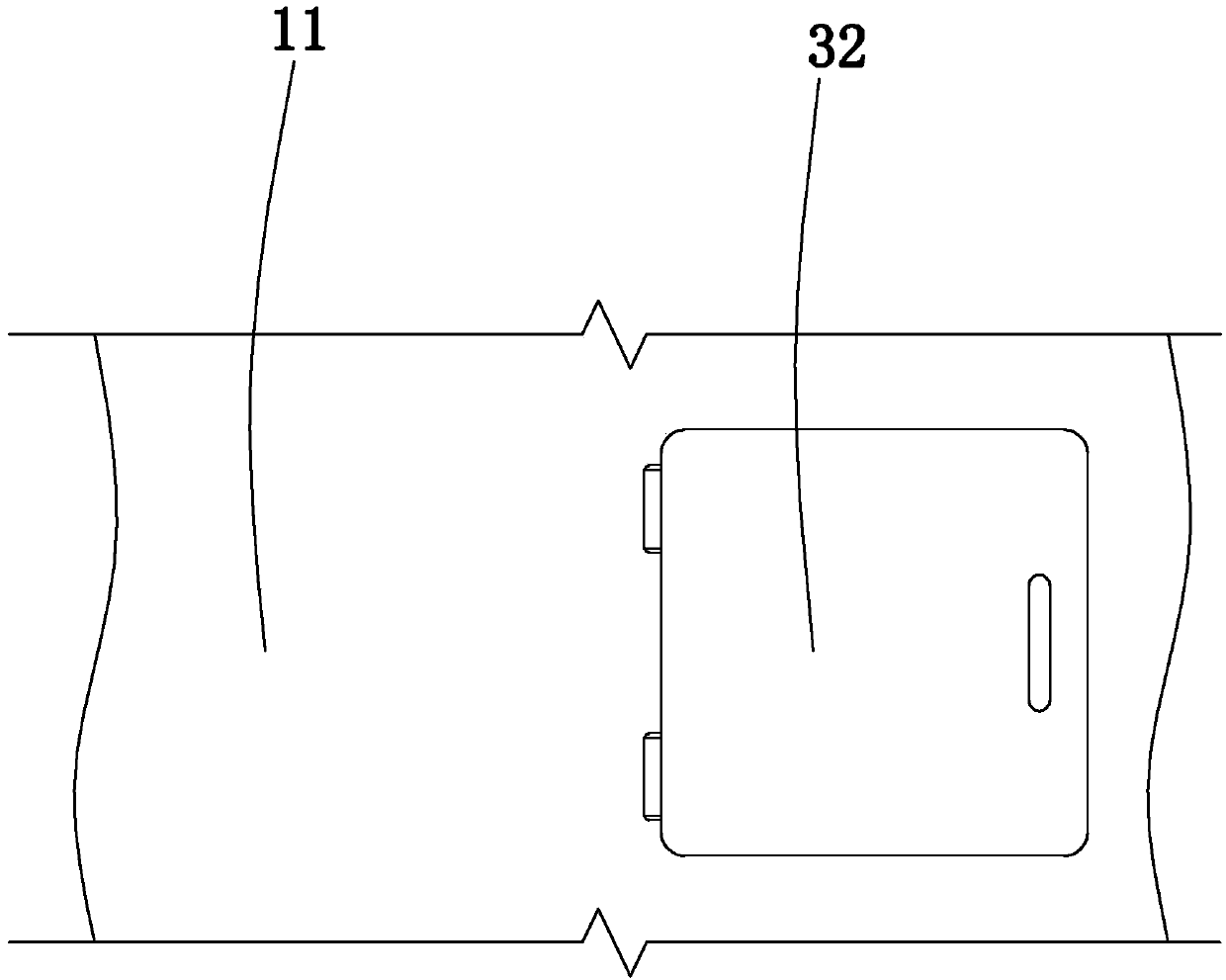

[0034] The air-conditioning duct structure corresponds to the long side wall one by one. In the corresponding air-conditioning duct structure and the long side wall: the air-conditioning duct structure includes a wall air duct 31 arranged on the long side wall and can be used to close The opening and closing door 32 at the inner end of the wall air passage, the opening and closing door is in the grain storage bin body;

[0035] An air guide fan 2a is arranged in the outer air duct, which includes a front curved pipe section 21, a rear curved pipe section 22 and a buried horizontal pi...

Embodiment 2

[0042] Embodiment 2: the basic structure and implementation mode of this embodiment are the same as embodiment 1, and its difference is, as Figure 7 to Figure 12 As shown in , in the corresponding air-conditioning air duct structure and long side wall: the air-conditioning air duct structure also includes a rear glue leveling cylinder 36 arranged on the long side wall, and the long side wall is provided with several The first rubber storage tube 61 in the side wall, the second rubber storage tube 62 embedded in the long side wall and the third rubber storage tube 63 embedded in the long side wall, the wall air channel is cylindrical, and the wall air channel diameter Upward, the first rubber storage tube is between the inner sealing ring and the wall air passage, the second rubber storage tube is between the inner sealing ring and the outer sealing ring, and the third rubber storage tube is between the outer sealing ring and the outer edge of the bottom film;

[0043] One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com