Ventilation and cooling performance configuration method, device and tower for high tower tower

A technology of ventilation cooling and configuration method, which is applied to wind power generation, wind turbines, machines/engines, etc., can solve the problems of different heat dissipation, timely discharge of heat from towers, and high towers, and achieves a simple configuration method, improves ventilation performance, Efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

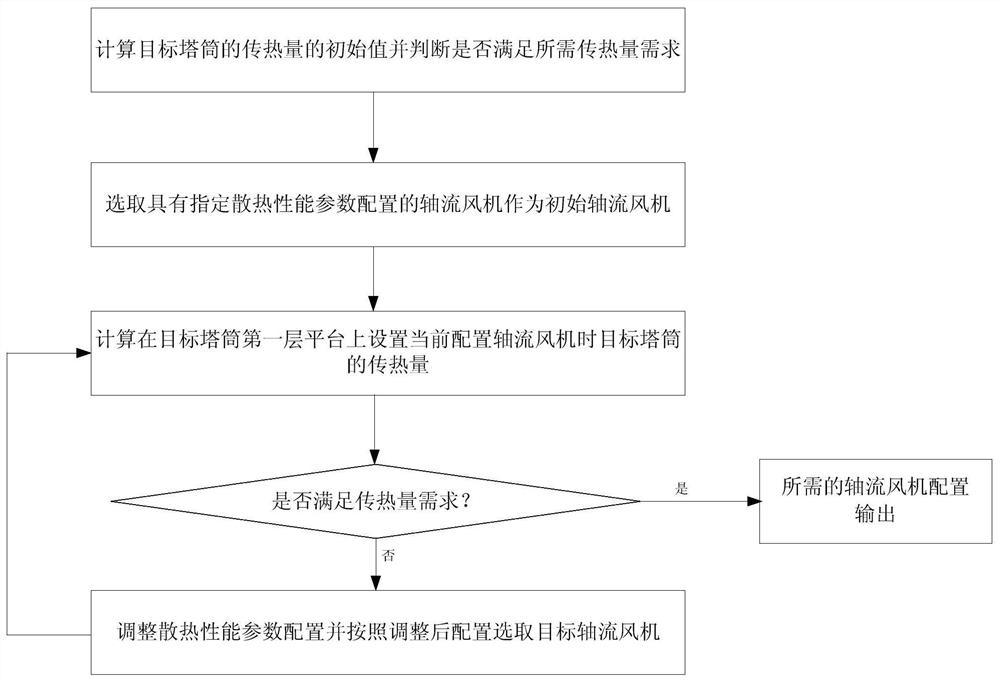

[0064] Such as figure 1 As shown, this embodiment is used for the ventilation and cooling performance configuration method of a high tower tower, and the steps include:

[0065] S1. Calculate the initial value of the heat transfer value of the target tower and judge whether the required heat transfer requirement is met, if not, proceed to step S2;

[0066] S2. Select an axial flow fan with a specified heat dissipation performance parameter configuration as the initial axial flow fan;

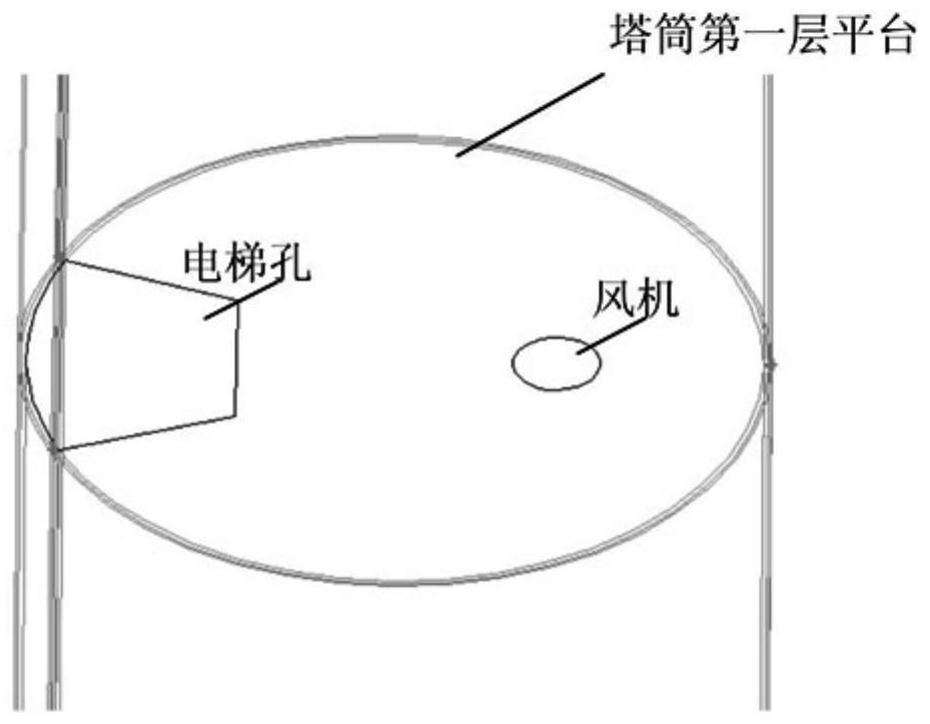

[0067] S3. Calculate the heat transfer of the target tower when the axial flow fan is currently configured on the first platform of the target tower, and judge whether the required heat transfer is met. If not, adjust the heat dissipation performance parameter configuration and follow the adjusted configuration Select the target axial flow fan, return to step S3, and output the required heat dissipation performance parameter configuration of the axial flow fan if it is satisfied.

[0068] In t...

Embodiment 2

[0126] Hereinafter, the present invention will be further described by taking the ventilation and cooling performance configuration of a 2MW double-fed high-tower wind power generating set as an example.

[0127] Step 1: Determine the calculation conditions according to the structure and materials of the tower, the configuration and requirements of the ventilation and cooling system of the converter, and the design ambient temperature. The specific calculation parameters for the heat transfer capacity of the tower wall are shown in Table 1.

[0128] Table 1: Parameter setting table for calculating the heat transfer capacity of the tower wall.

[0129]

[0130]

[0131] Step 2: Calculate the heat transfer coefficient of the tower according to the structure of the tower.

[0132]According to the configuration in Table 1, the air convection heat dissipation method in the tower is regarded as forced convection in the tube, and the convective heat transfer coefficient Kin is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com