Heat dissipation type power cabinet with targeted directional cooling function

A directional cooling and heat dissipation technology, applied in the cooling/ventilation of substation/switchgear, electrical components, substation/switch layout details, etc., can solve the problems of damage to electrical components of power cabinets, easy heat accumulation, low heat dissipation efficiency, etc. , to avoid shortening the service life, better heat dissipation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

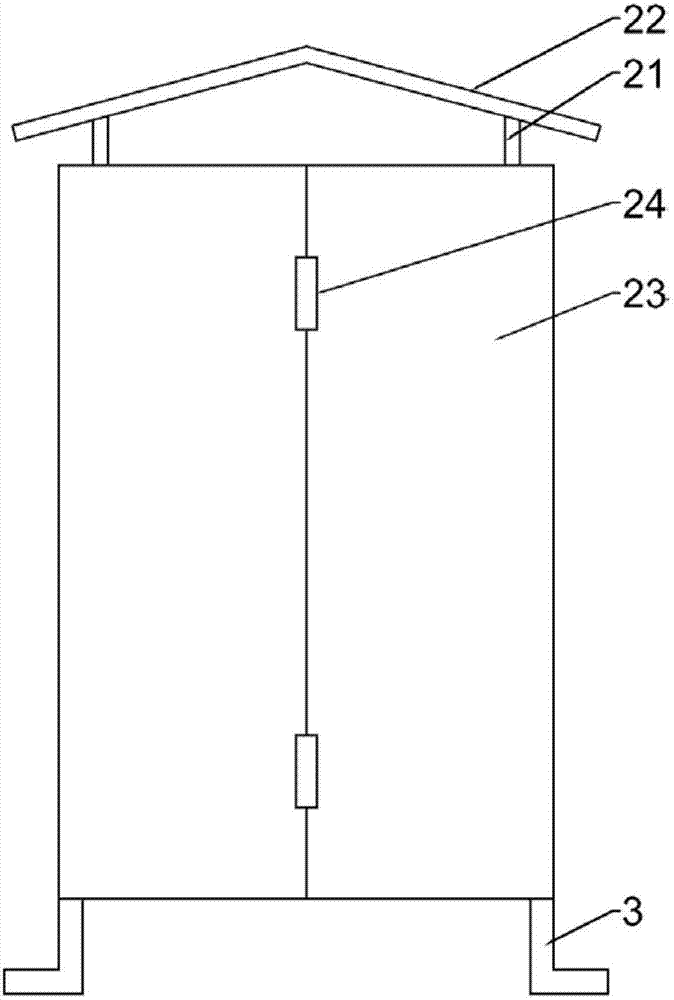

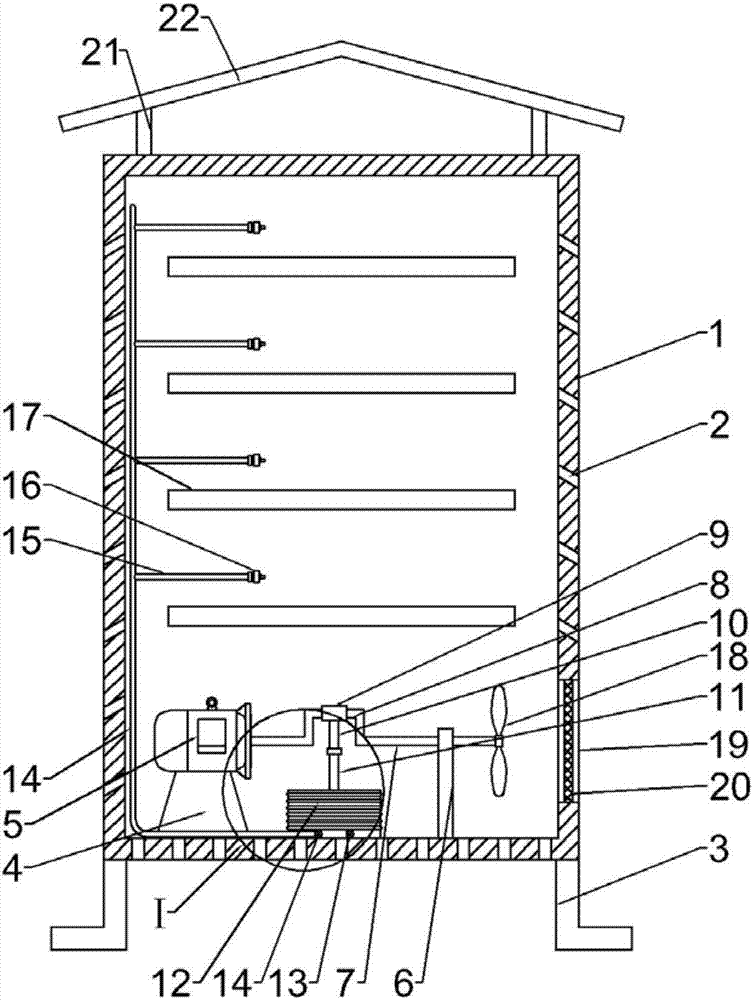

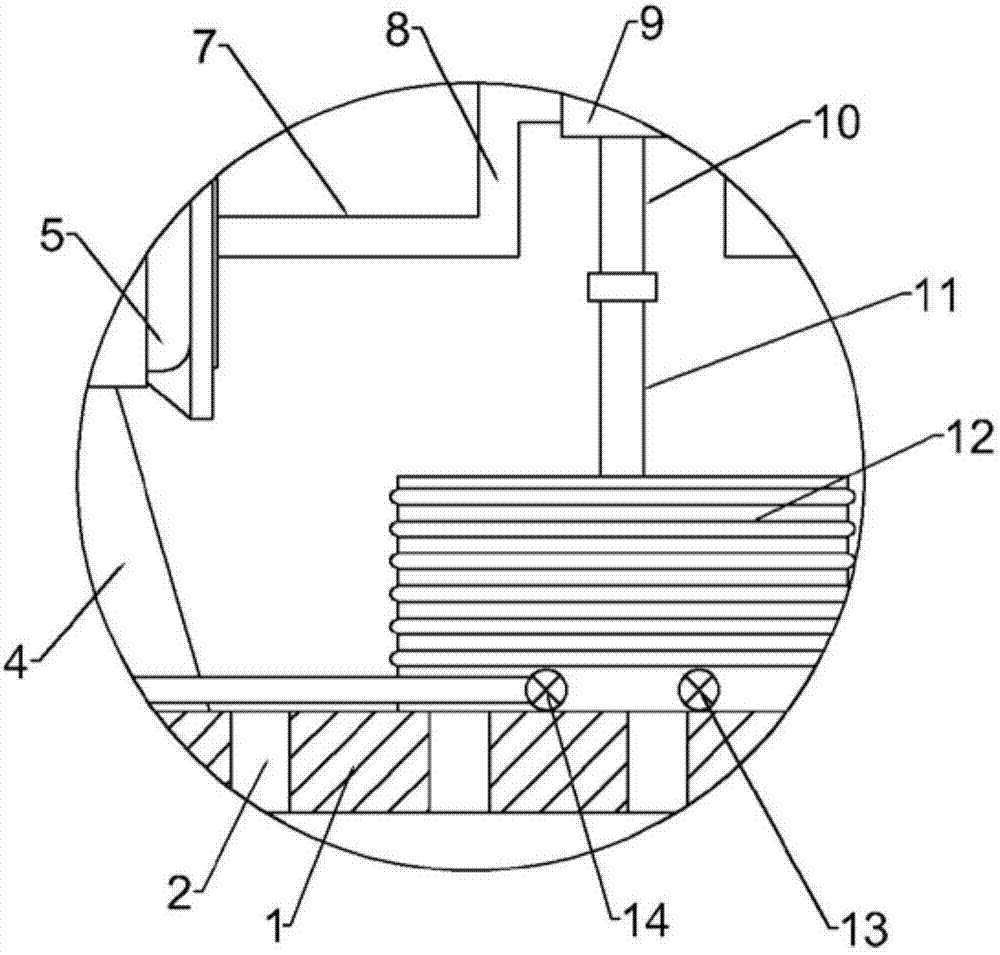

[0019] see Figure 1-3 , a heat-dissipating power cabinet with a targeted directional cooling function, comprising a cabinet body 1, a plurality of cooling holes 2 are opened on the outside of the cabinet body 1, and a motor base 4 is fixedly connected to the left side of the inside of the cabinet body 1, and the motor base 4 is fixedly connected with a motor 5 above, the inner bottom of the cabinet 1 is fixedly connected with a bearing seat 6, the upper part of the bearing seat 6 is rotatably connected with a rotating shaft 7, the rotating shaft 7 is connected with the motor 5, and the middle part of the rotating shaft 7 is fixedly connected There is a bell crank 8, and a transmission ring 9 is provided on the outer side of the bell crank 8. The lower side of the transmission ring 9 is fixedly connected with a first connecting rod 10, and the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com