Embedded touch OLED display device and manufacture method thereof

A technology of a display device and a manufacturing method, which are applied in the directions of instruments, electrical digital data processing, input/output process of data processing, etc., can solve the problems of increasing the thickness of an OLED touch display screen, which is disadvantageous to the thinning of the OLED touch display screen, and the like. Achieve the effect of improving lightness, saving production costs and simplifying production processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

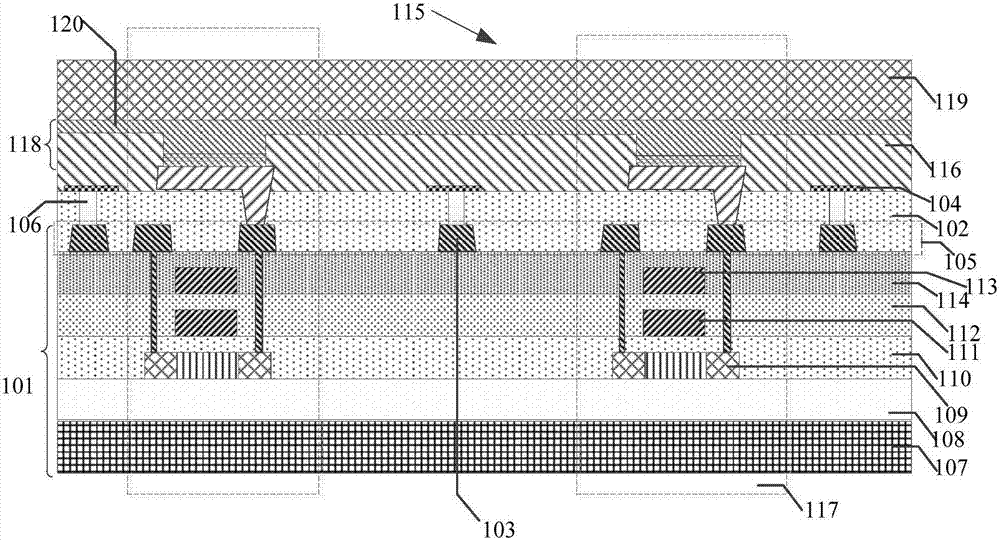

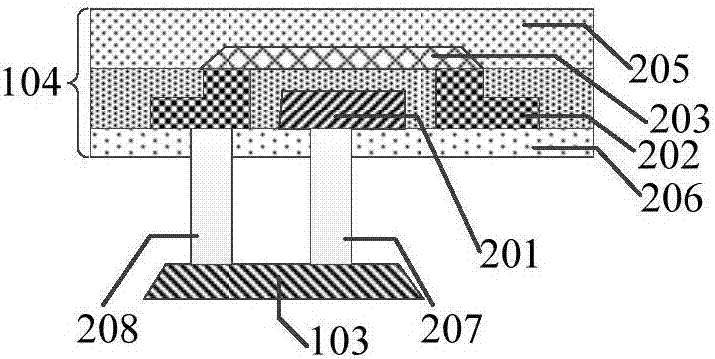

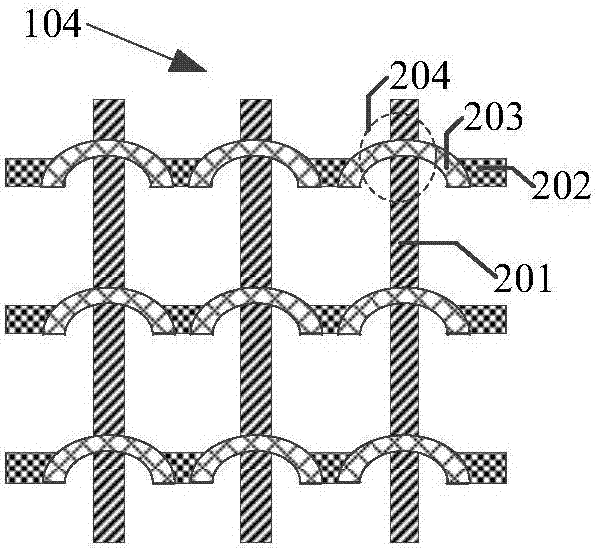

[0021] Please also refer to figure 1 , Figure 2A and Figure 2B , figure 1 It is a structural schematic diagram of the first embodiment of the embedded touch OLED display device of the present application; Figure 2A yes figure 1 A structural schematic diagram of a part of the structure of the touch electrode layer of the embodiment; Figure 2B yes figure 1 A schematic structural diagram of the overall structure of the touch electrode of the embodiment. This embodiment includes: an array substrate 101, an organic planar layer 102, a plurality of leads 103, and a touch electrode layer 104; wherein, the array substrate 101 is provided with a source-drain layer 105, and the plurality of leads 103 are in the same layer as the source-drain layer 105 setting; a plurality of through holes 106 are arranged on the organic planarization layer 102; the touch electrode layer 104 is arranged on the side of the organic planarization layer 102 away from the array substrate 101; A plu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com