Peripheral reinforcing stiffened plate axial pressure test mechanism

A technology of axial compression test and stiffened plate, which is applied in the direction of measuring devices, instruments, scientific instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with examples in conjunction with the accompanying drawings.

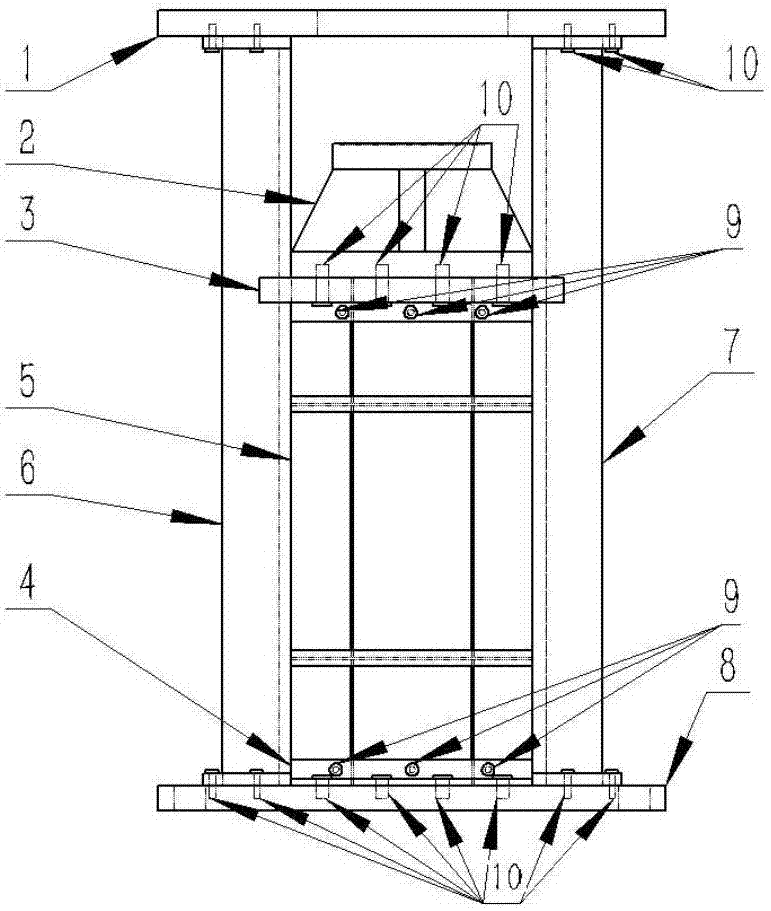

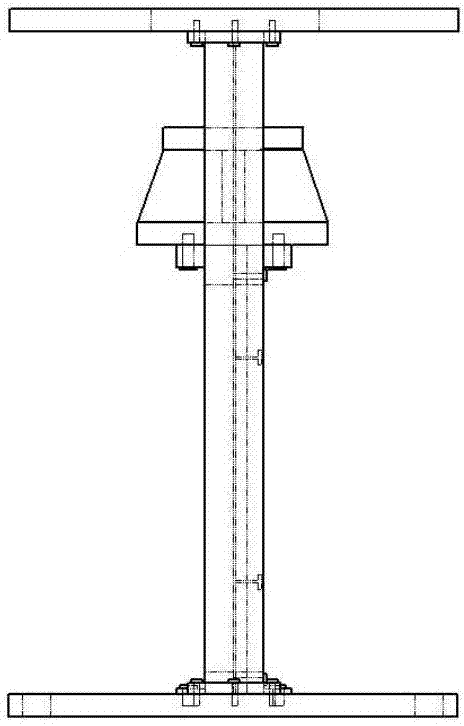

[0021] The present invention is composed of 1. loading structure 2, upper clamp 3, lower clamp 4, stiffened plate test piece 5, bottom base 8, fastening bolt 9 and connecting bolt 10.

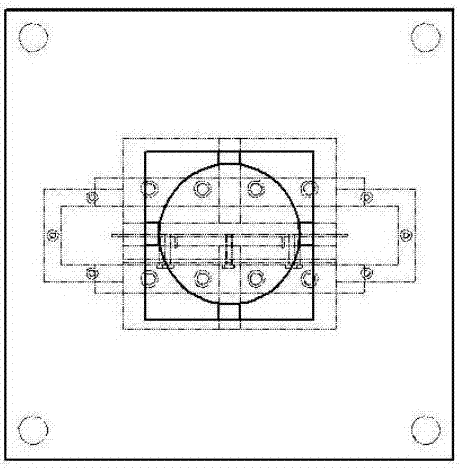

[0022] The stiffened plate specimen 5 is clamped between the left vertical rail 6 and the right vertical rail 7 , the upper part is connected with the upper clamp 3 through fastening bolts 9 , and the lower part is connected with the lower clamp 4 through fastening bolts 9 . The lower end fixture 4, the bottom of the left vertical rail 6, and the bottom of the right vertical rail 7 are fixed to the bottom base 8 through connecting bolts 10, and the bottom base 8 can be connected to any test site base through holes. The upper part of the upper end clamp 3 is connected with the loading structure 2 through connecting bolts 10 . The upper cover plate 1 is connected to the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com