Solid sample division device

A shrinking device and sample technology, applied in the field of solid sample shrinking device, can solve the problems of dirty air in the laboratory, unfavorable respiratory health of experimenters, and reduction of sample volume, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

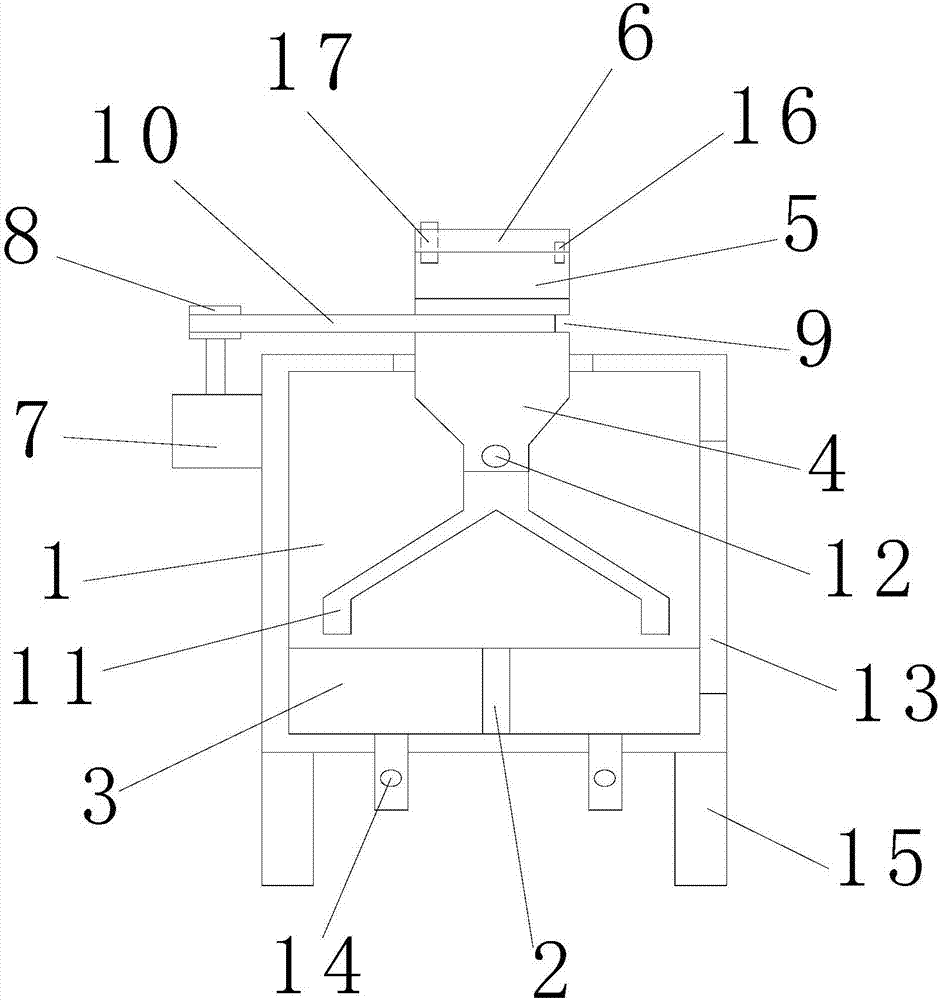

[0017] refer to figure 1 , a kind of solid sample shrinkage device of the present invention, comprises outer cylinder 1, dividing plate 2, receiving chute 3, lower hopper 4, standard sieve 5, cover plate 6, motor 7, belt pulley 8, belt groove 9, belt 10 , a material distribution inclined pipe 11, a feeding valve 12, an inspection door 13, a discharge valve 14 and a support leg 15, and the inner bottom of the outer cylinder 1 is fixed with a plurality of partition plates 2 along the radial direction to separate the outer cylinder 1 The bottom of the inside is divided into a plurality of receiving troughs 3 with equal areas. The center position of the upper part of the outer cylinder 1 can be rotated to be provided with a vertically arranged lower hopper 4, and the upper part of the lower hopper 4 is fixedly equipped with a standard screen. 5. The upper part of the standard sieve 5 is rotatably provided with a horizontally arranged cover plate 6 through the rotating shaft 16, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com