Range hood structure

The technology of a range hood and a wind wheel is applied in the directions of removing oil fume, household heating, heating methods, etc., which can solve the problem of inability to clean viscous and large oil stains, and achieves good cleaning effect and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

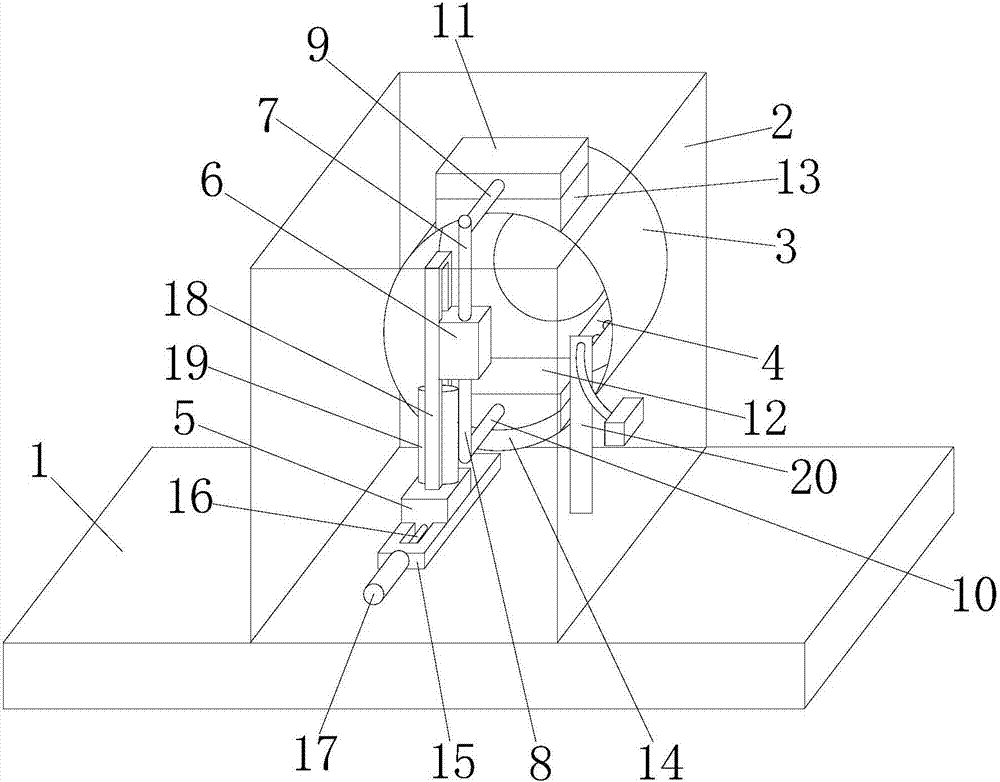

[0014] Such as figure 1 As shown, a range hood structure includes a range hood panel 1 and an air chamber 2 connected to the top of the range hood panel 1. The rear side of the air chamber 2 is rotated and installed with a wind wheel 3, and the air chamber 2 is also installed with a The atomizing nozzle 4, the atomizing nozzle 4 is close to the side of the wind wheel 3 and the air outlet of the atomizing nozzle 4 is aligned with the inside of the wind wheel 3, and the bottom of the air chamber 2 slides along the front and rear horizontal direction and is equipped with a sliding block 5, which slides down An upper slider 6 is vertically slidably mounted on the top of the block 5, and the top and bottom surfaces of the upper slider 6 are vertically connected with connecting rods 7 and 8 respectively, and the rod ends of the two connecting rods 7 and 8 are respectively vertically connected with a support arm 9 , 10, wherein the upper support arm 9 hangs above the top of the wind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com