Lifting-type maintenance platform system for tower frame of wind generation set

A technology of wind turbines and lifting platforms, which is applied in the direction of wind power generation, wind engines, installation/support of wind engines, etc., to achieve the effects of increased load, simple structure, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

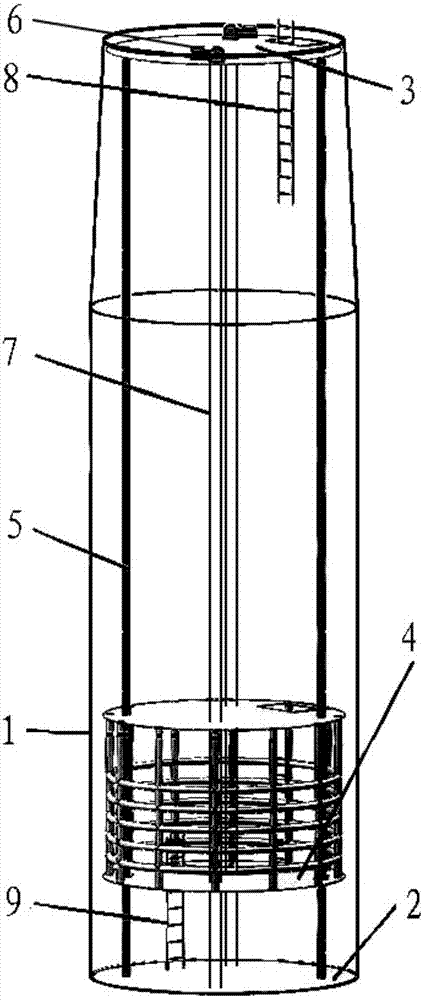

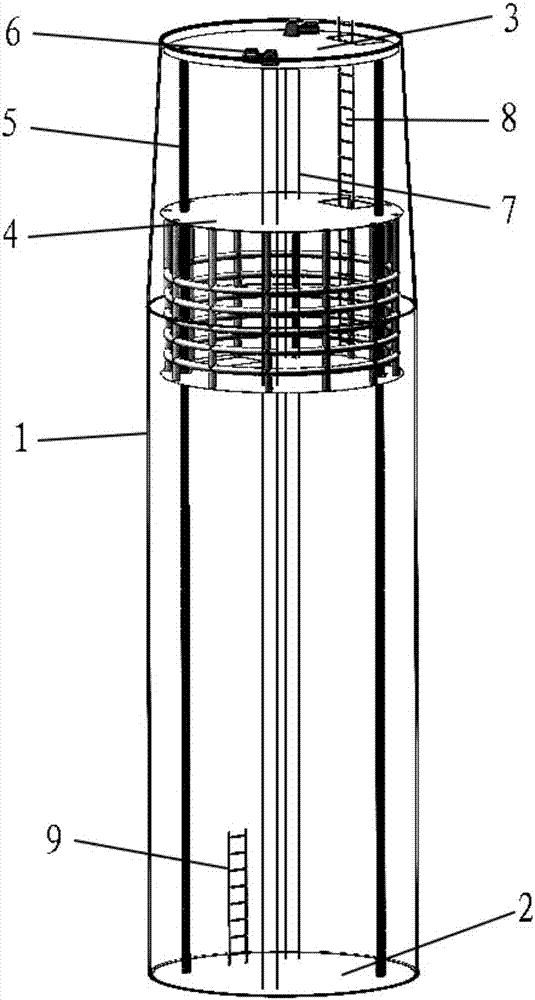

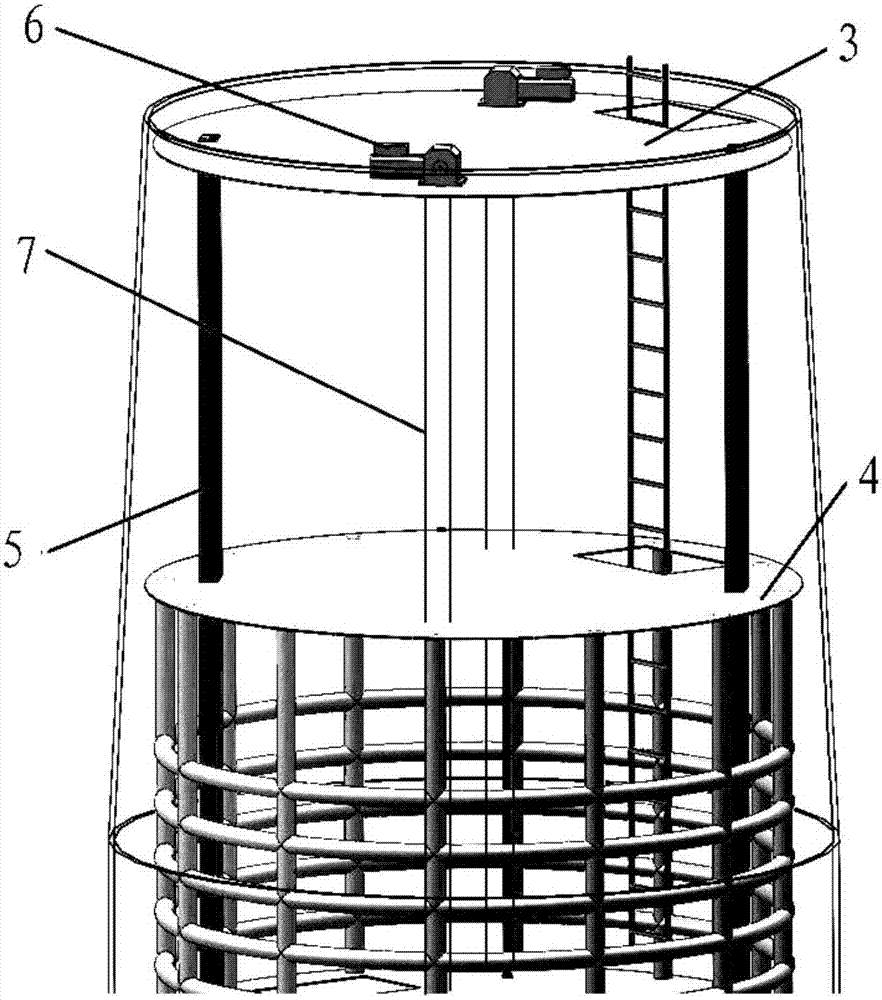

[0029] see Figure 1 to Figure 3 As shown, the wind turbine tower lifting maintenance platform system of the present invention includes a driving device, an actuator, a monitoring device and a control unit. It can be started and stopped at any position according to the operation and maintenance requirements, and can be automatically lifted. It has a simple structure and is easy to use. .

[0030] Specifically, the top and bottom of the tower 1 are provided with a top platform and a bottom platform 2 respectively. The top platform is usually a torsion platform. This embodiment uses the torsion platform as an example to illustrate the technical solution of the present invention.

[0031] The driving device includes a platform hanging beam, a driving motor 6, a traction wheel, a driving wire rope 7, a steering wheel and a tensioning device; What is more is a right-angle geared motor, which can rotate forward and reverse. The output shaft of the right-angled geared motor is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com