Sprue cap

A nozzle and liquid injection technology, applied in the field of filler caps, can solve the problems of fuel leaking out of the vehicle and foreign matter mixed into the tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

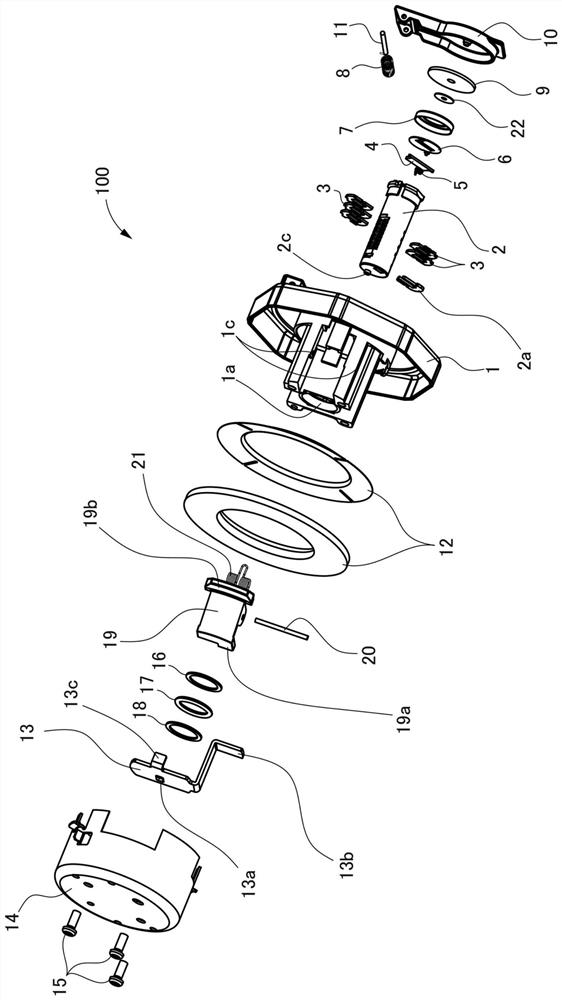

[0071] figure 1 It is an exploded perspective view of the sprue cap according to this embodiment.

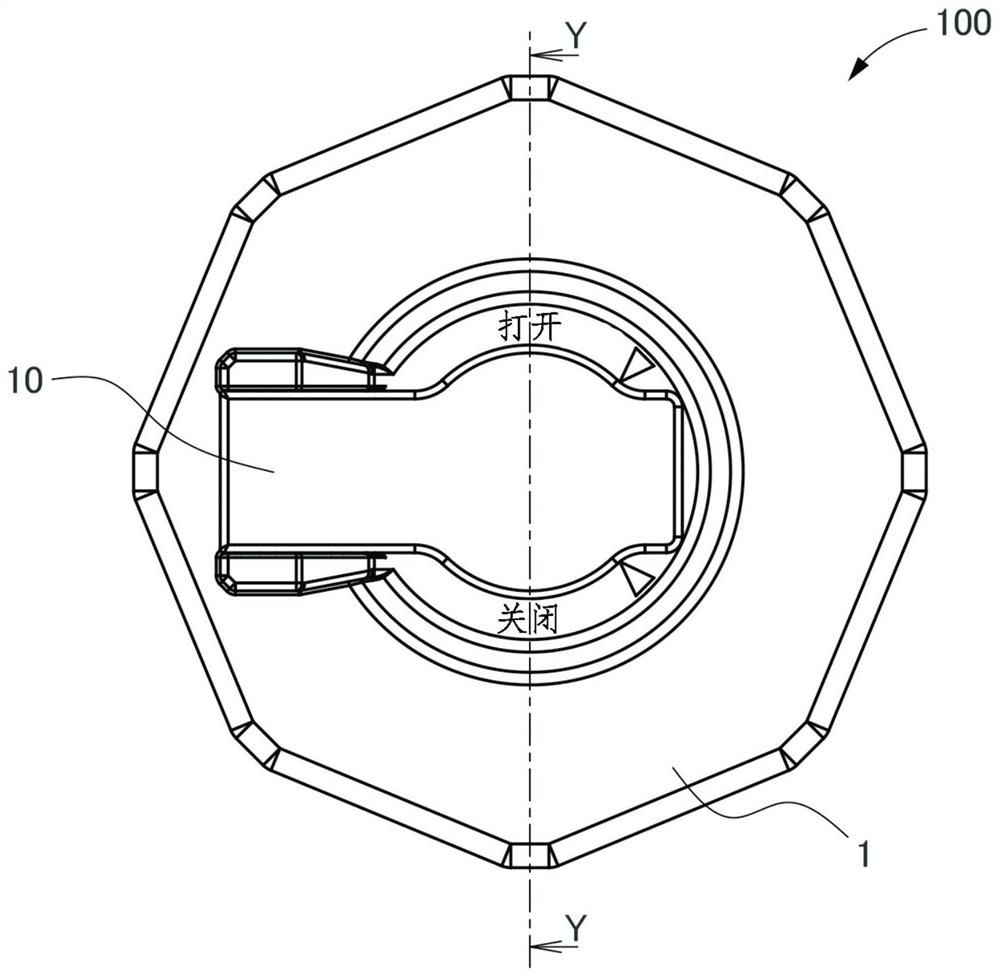

[0072] figure 2 is a front view of the sprue cap 100 .

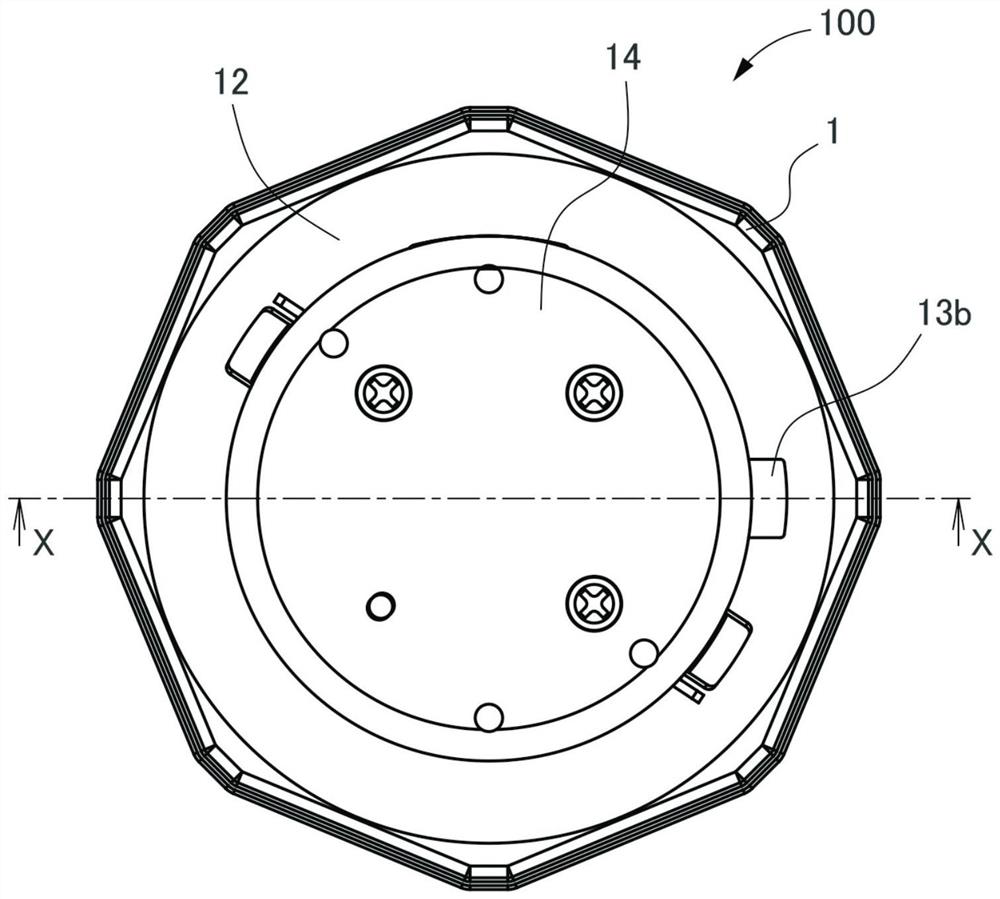

[0073] image 3 is a rear view of the sprue cap 100 .

[0074] Figure 4 is in figure 2 The cross-sectional view after cutting the sprue cover 100 at the position of the arrow YY in .

[0075] Figure 5 is in image 3 The cross-sectional view of the sprue cover 100 is cut at the position of the arrow XX in the figure.

[0076] In addition, in the following description, although specific numerical values, shapes, materials, etc. are shown and demonstrated, these can be changed suitably.

[0077] Also, in the description below, figure 1 middle right, Figure 4 middle left, figure 2 in front of the eyes, image 3 The depth side in is set to "Front", figure 1 middle left, Figure 4 middle right, figure 2 in the depth side, image 3 In the description, the front side in front of the eye is referred to as "r...

no. 2 approach

[0128] Figure 14 It is a perspective view showing the sprue cap 200 of the second embodiment in a state attached to the injection pipe P and in which the core body 2 is located at the locked position.

[0129] In the second embodiment, the restricting member 219 is used as a member that moves linearly, and the locking portion 213c of the locking member 213 is provided further forward than the first embodiment, which is the main difference from the first embodiment. change. In addition, the sprue cap 200 of the second embodiment is the same as that of the first embodiment except that the forms of the locking member 213, the restricting member 219, and the return spring 221 are different from those of the first embodiment. Therefore, parts that realize the same functions as those in the first embodiment described above are assigned the same symbols, and redundant descriptions are appropriately omitted.

[0130] The locking member 213 is formed by pressing a sheet metal materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com