Protective shed structure for continuous girder crossing on-active-duty highway and construction method of protective shed structure

A construction method and the technology of protective sheds, which are applied in the direction of building structure, construction, and construction materials, can solve the problems of high requirements and difficult construction of protective sheds, and achieve the effect of reducing the difficulty of demolition and improving technical and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

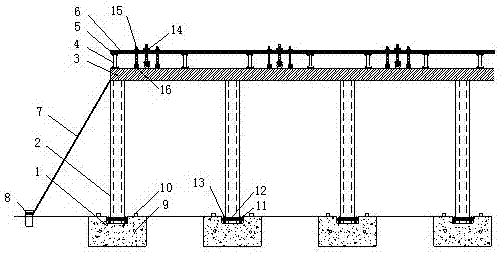

[0038] Hereinafter, the present invention will be further described in conjunction with the accompanying drawings in the specification. The construction technical requirements of the protective shed will not be repeated in the present invention, but the structure and construction method involved in the present invention will be emphasized.

[0039] Such as Figure 1-9 As shown, a continuous beam protection shed structure across an active highway and its construction method includes a strip foundation 1, a column 2, a horizontal distribution beam 3, a longitudinal distribution beam 4, a shock-absorbing wood board 5, a waterproof board 6, and a cable wind rope 7 , Steel pipe pile 8, steel pipe reserved hole 9, hoisting reserved hole 10, steel plate 11, connecting plate 12, embedded bolt 13, bolted pulley 14, fixing bolt 15, wire sleeve 16, reserved hoisting hole 17 And strap hole 18.

[0040] There is a strip foundation 1 in the ground soil layer. The size of the strip foundation 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com