A rapid prototyping device for metal components

A metal component and fast technology, applied in the field of metallurgy, can solve the problems of low quality and low efficiency, and achieve the effects of low production raw materials and production organization requirements, improved production efficiency, and short manufacturing process cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

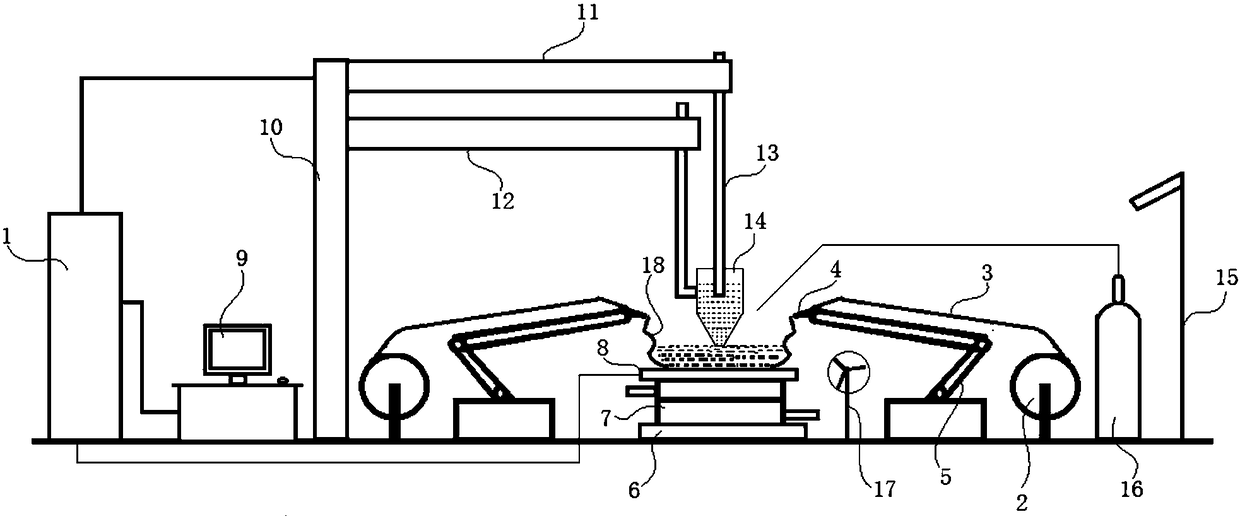

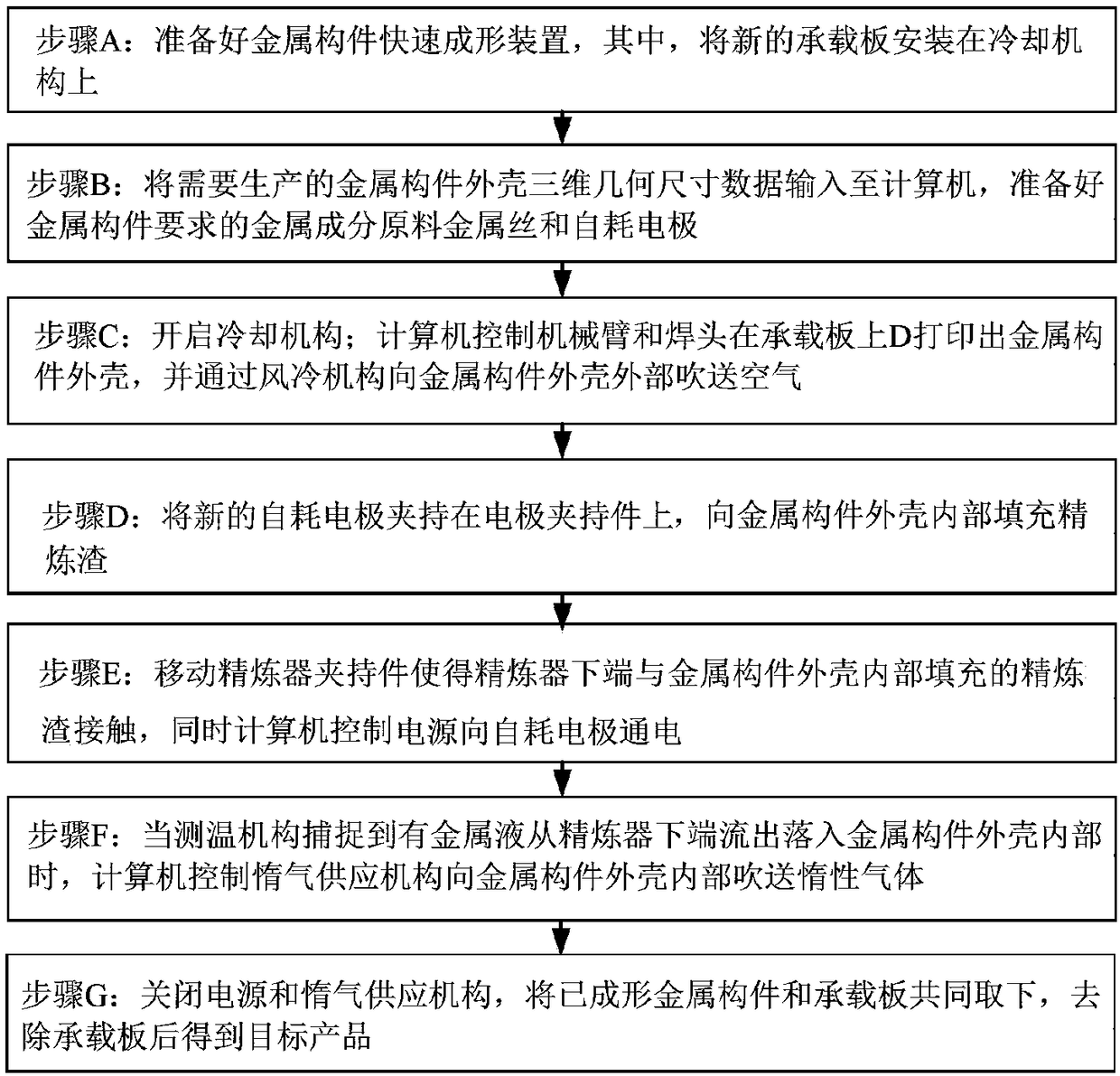

[0033] to combine figure 1 , the rapid prototyping device for metal components in this embodiment includes a power supply 1, a consumable electrode 13, a refiner 14, and an additive manufacturing mechanism connected to a computer 9; the additive manufacturing mechanism is used to 3D print out The metal component shell 18, the printed metal component shell 18 is filled with refining slag, wherein the bearing plate 8 is a metal plate, the bearing plate 8 is placed on the cooling mechanism 7, the cooling mechanism 7 is a cooling device for a water-cooled box, and the cooling mechanism 7 is set On the insulating plate 6; the refiner 14 is composed of upper and lower sections, the upper section is a hollow cylinder, the lower section is an inverted hollow round table, the upper section and the lower section are seamlessly welded together, the lower end of the refiner 14 faces the inside of the metal component shell 18, The refiner 14 is filled with refining slag; the consumable ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com