A superheating device for industrial incineration boilers

A boiler and superheating technology, used in lighting and heating equipment, incinerators, steam superheating, etc., can solve the problems of repeated occurrence, short operation period of superheater, easy to burst pipes, etc., to prolong the operation period and avoid flue gas corridors. , the effect of reducing the problem of pipe bursting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Such as figure 1 As shown, a superheating equipment for industrial incineration boilers includes several heat exchange tubes arranged in the furnace chamber 1, the heat exchange tubes include a first heat exchange tube 3 and a second heat exchange tube 4, the heat exchange tubes The heat pipes are all vertically arranged in the furnace chamber 1 with equal intervals between them. The furnace chamber 1 also includes an inlet header 5, an outlet header 6 and a U-shaped overheating pipe 7. The inlet header The box 5 is used to connect the first heat exchange tube 3 and the U-shaped overheating tube 7, and the outlet header 6 is used to connect the second heat exchange tube 4 and the U-shaped overheating tube 7. The furnace cavity 1 also includes a first metal filter plate 8 and a second metal filter plate 9, the first metal filter plate 8 and the second metal filter plate 9 are arranged horizontally, and both ends are connected to the furnace wall 10, so The first metal f...

Embodiment 2

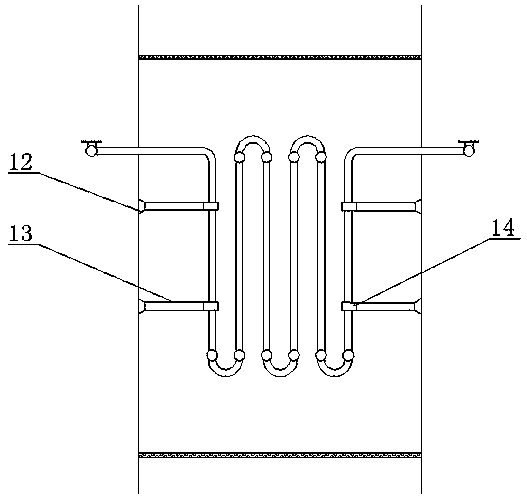

[0021] Example two as figure 2 As shown, the furnace cavity 1 also includes a lateral positioning device 12, the lateral positioning device 12 includes a first connecting rod 13 arranged on the furnace wall 10, and the first connecting rod 13 is used to connect the first Pipe clamp 14, the first pipe clamp 14 is used to clamp the heat exchange tube.

[0022] Specifically, in order to maintain the transverse pitch of the heat exchange tubes and the flatness of the tube bundle plane, a first tube clamp 14 is installed on the heat exchange tubes, and the first tube clamp 14 is connected to the transverse positioning device 12 The first connecting rod 13 is connected, and the upper and lower parts of the heat exchange tubes are clamped by the first pipe clamp 14. In order to ensure that the first pipe clamp 14 has sufficient strength at high temperature, the material selection Cr18Ni9Ti.

Embodiment 3

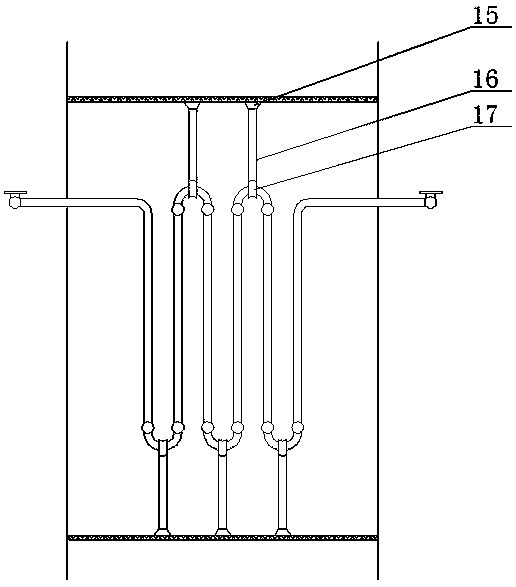

[0024] Such as image 3 As shown, the furnace cavity 1 also includes a longitudinal positioning device 15, and the longitudinal positioning device 15 includes a second connecting rod 16 arranged on the first metal filter plate 8 and the second metal filter plate 9, so The second connecting rod 16 is used for connecting the second pipe clamp 17, and the second pipe clamp 17 is used for clamping the U-shaped overheating pipe 7.

[0025] Specifically, in addition to adding a horizontal positioning device 12 to limit the lateral displacement of the superheated tube, it is also necessary to add a longitudinal positioning device 15, which can reduce the radiation of the superheated tube by high-temperature flue gas, and the vertical positioning device 15 and the first A metal filter plate 8 and the second metal filter plate 9 are welded to have good heat conduction effect and relatively fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com