Fast leaking stoppage device and leaking stoppage method for strongly-permeable and loose stratum

A plugging method and strong permeable technology, applied in construction, infrastructure engineering and other directions, can solve the problems of not being able to meet the requirements of anti-seepage plugging, high operating level requirements, and the diffusion range of blocked pipes, so as to achieve fast and effective plugging. Leakage effect, good connectivity, large void effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

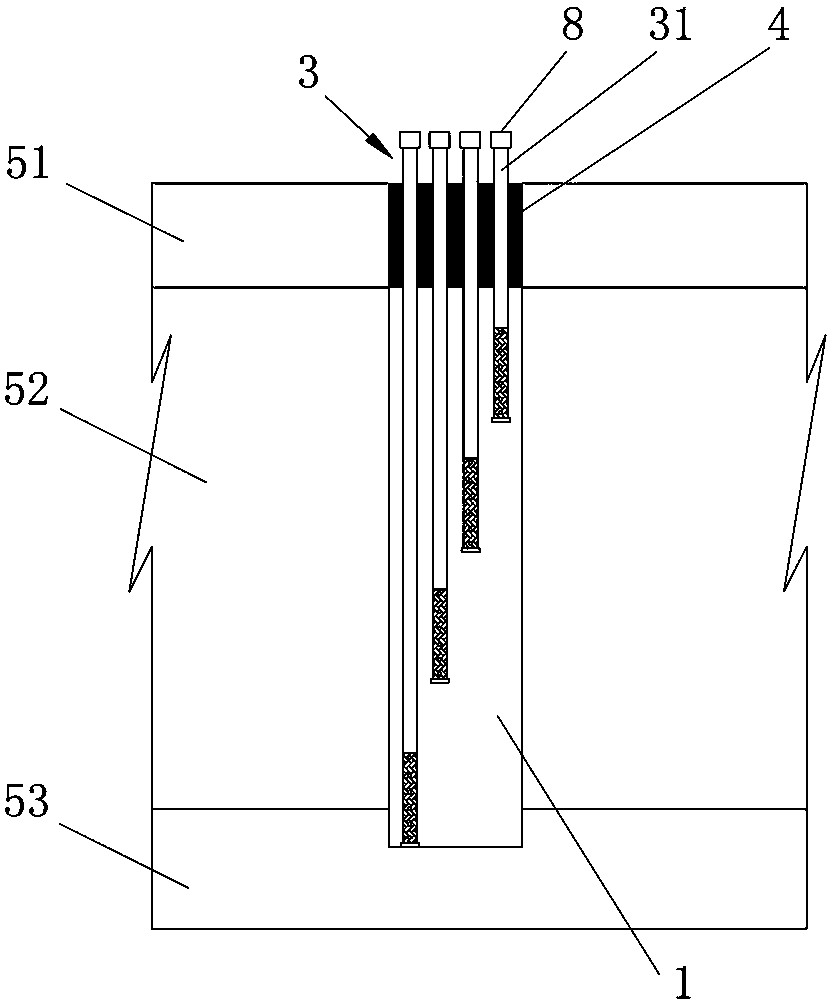

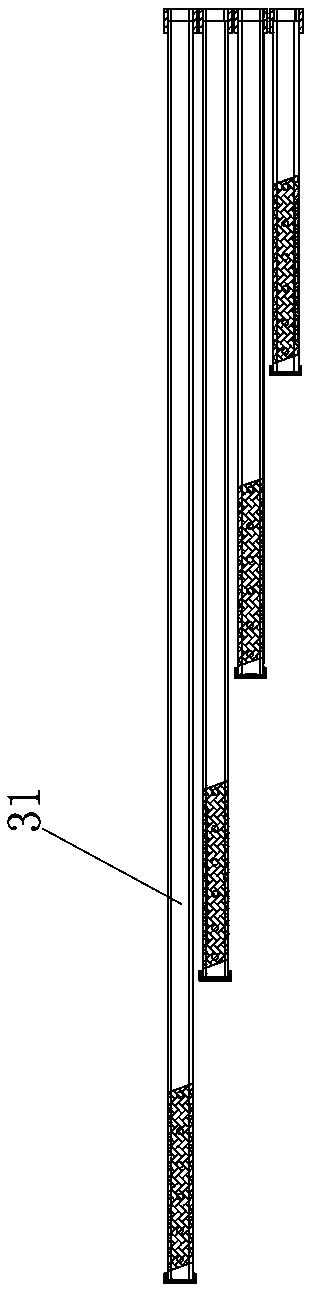

[0036] Such as Figure 1 to Figure 3 As shown, the rapid plugging device for highly permeable and loose formations of this embodiment includes a drilling tool 2 for drilling the grouting hole 1, a combined floral tube 3, and a hole for the combined floral tube 3 to be inserted into the grouting hole 1 to the grouting hole 1 The sealing plug body 4 for sealing the mouth, the combined flower tube 3 includes at least one group of grouting tube groups, each group of grouting tube groups includes two grouting tubes 31, the lower end of the grouting tubes 31 is closed, and the upper end extends out of the hole of the grouting hole 1 Grouting eyes 311 are provided on the lower end surface or the lower peripheral surface of the grouting pipe 31, and the heights of the lower end surfaces of all the grouting pipes 31 in the grouting hole 1 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com