Cordwood temporary support base structure and construction method thereof

A temporary support and construction method technology, applied in construction, bridge construction, bridges, etc., can solve the problems of inability to preheat resistance lines, long construction period, delayed construction period, etc. The effect of high installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

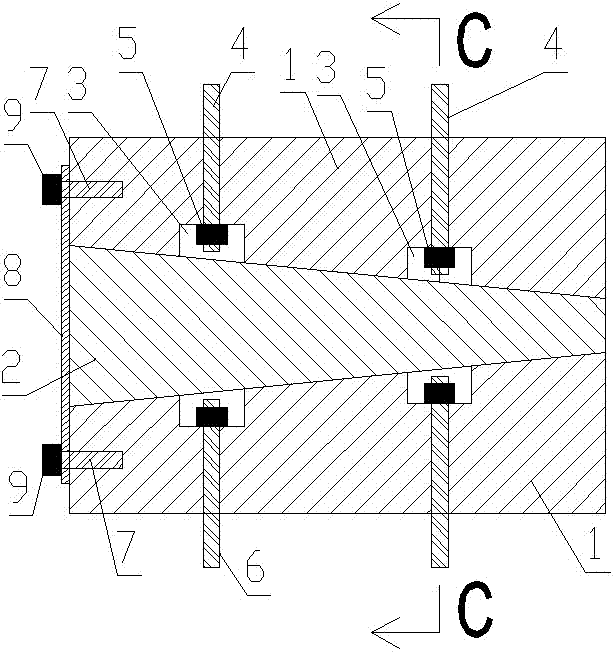

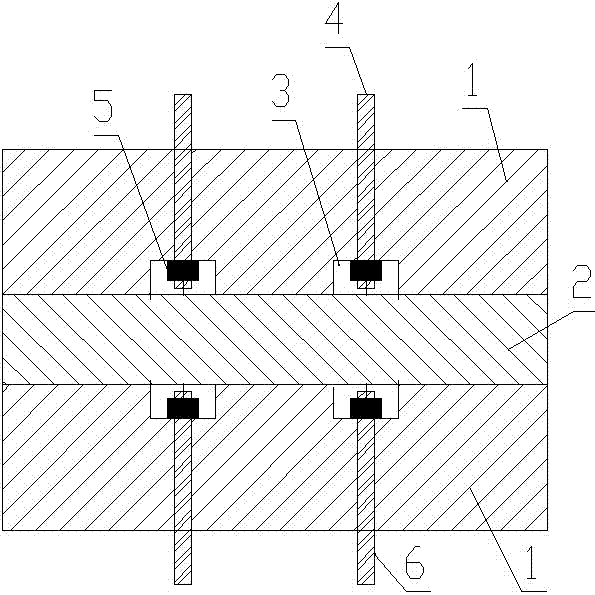

[0034] Such as Figure 1 to Figure 8 As shown, the building block type temporary support structure of the present invention includes a beam body 10, a pier 11 and a support unit assembled from 2 A standard blocks 1 and 1 B standard block 2, and the length and width of the A standard block 1 Both are the same length and width as the B standard block 2; the vertical section of the A standard block 1 is a right-angled trapezoid, and the vertical section of the B standard block 2 is an isosceles trapezoid; the shorter bottom of the trapezoid is the upper bottom and the longer The bottom is the lower bottom; four bolt grooves 3 are evenly arranged in the middle of the slope of A standard block 1, and each bolt groove 3 is connected with a vertical light hole that runs through A standard block 1, and the other opening of the vertical light hole is located at A The plane where the right-angled side of the section of standard block 1 is located; the plane where the upper bottom of A s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com