Wolfberry and sea-buckthorn fruit juice and preparation method thereof

A technology of seabuckthorn juice and wolfberry fresh fruit, which is applied in the direction of food ingredients as color, food ingredients as taste improver, food ingredients as odor improver, etc. It can solve the problems of poor taste and quality, limited consumer groups, etc., and facilitates industrialization Large-scale production, suitable for a wide range of people, and rich in nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

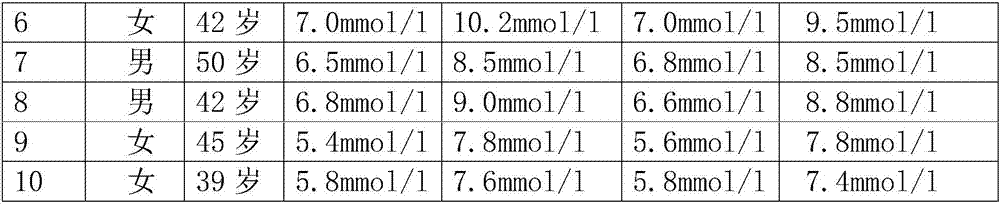

Examples

Embodiment 1

[0049] After crushing 94kg of wolfberry fresh fruit with a colloid mill, filter with a 60-mesh sieve to obtain the first wolfberry pulp, wolfberry seeds and wolfberry peel mixture;

[0050] sending the mixture of wolfberry seeds and wolfberry peel into an ultrafine mill for crushing, and then filtering through a 60-mesh screen to obtain the second wolfberry pulp;

[0051] After cleaning and draining the picked seabuckthorn, use a juice slag separation crusher to beat, and then filter through a 120-mesh screen to obtain seabuckthorn puree;

[0052] Mix the first wolfberry pulp and the second wolfberry pulp, concentrate at 90°C for 20 minutes, and when the sugar content reaches 23%, add 10 kg of seabuckthorn puree and continue stirring for 20 minutes, stop the concentration when the sugar content is 22%, and carry out canning;

[0053] After filling the bottled / bagged fruit juice, put it into a 90°C thermostat for 20 minutes to sterilize, then spray the device with warm and cold...

Embodiment 2

[0059] After crushing 94kg of wolfberry fresh fruit with a colloid mill, filter with a 60-mesh sieve to obtain the first wolfberry pulp, wolfberry seeds and wolfberry peel mixture;

[0060] sending the mixture of wolfberry seeds and wolfberry peel into an ultrafine mill for crushing, and then filtering through a 60-mesh screen to obtain the second wolfberry pulp;

[0061] After cleaning and draining the picked seabuckthorn, use a juice slag separation crusher to beat, and then filter through a 120-mesh screen to obtain seabuckthorn puree;

[0062] Mix the first wolfberry pulp and the second wolfberry pulp, concentrate at 90°C for 30 minutes, and when the sugar content reaches 23%, add 12 kg of seabuckthorn puree and continue stirring for 20 minutes, stop the concentration when the sugar content is 22%, and carry out canning;

[0063] After filling the bottled / bagged fruit juice, put it into a 90°C thermostat for 20 minutes to sterilize, then spray the device with warm and cold...

Embodiment 3

[0067] After crushing 94kg of wolfberry fresh fruit with a colloid mill, filter with a 60-mesh sieve to obtain the first wolfberry pulp, wolfberry seeds and wolfberry peel mixture;

[0068] sending the mixture of wolfberry seeds and wolfberry peel into an ultrafine mill for crushing, and then filtering through a 60-mesh screen to obtain the second wolfberry pulp;

[0069] After cleaning and draining the picked seabuckthorn, use a juice slag separation crusher to beat, and then filter through a 120-mesh screen to obtain seabuckthorn puree;

[0070] Mix the first wolfberry pulp and the second wolfberry pulp, concentrate at 90°C for 20 minutes, and when the sugar content reaches 23%, add 9 kg of seabuckthorn puree and continue stirring for 20 minutes, stop the concentration when the sugar content is 22%, and carry out canning;

[0071] After filling the bottled / bagged fruit juice, put it into a 90°C thermostat for 20 minutes to sterilize, then spray the device with warm and cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com