Damping adjusting and de-noising method of violin

A violin and damping technology, which is applied to violins, instruments, stringed instruments, etc., can solve the problems of ignoring the base research of supporting pronunciation parts, restricting the improvement of violin sound quality, etc., and achieve the effects of good damping adjustment, stable sound and clear pronunciation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for adjusting damping and eliminating noise of a violin, comprising: coating a 0.2mm thick nano-coating on the side of the violin end wood 1 adjacent to the headstock, and then drying it under hot air at 150°C for 30 minutes.

[0020] The method provided in embodiment 1 is used to process three new practice violins and an old European and American violin respectively. Compared with the sound of the same violin before and after processing, the violin sound is more stable and stable after being processed by the method provided in embodiment 1. Clearer and more expressive.

Embodiment 2

[0022] A method for adjusting damping and eliminating noise of a violin, comprising: coating a 0.1 mm thick nano-coating on the side of a violin tail wood 1, and then drying it under hot air at 140° C. for 40 minutes.

[0023] Adopt the method that embodiment 2 provides to process two new cellos respectively, compare the violin sound of cello before and after processing, the pronunciation of cello is stronger and more powerful after the method that embodiment 2 provides, and sound is thicker and fuller.

Embodiment 3

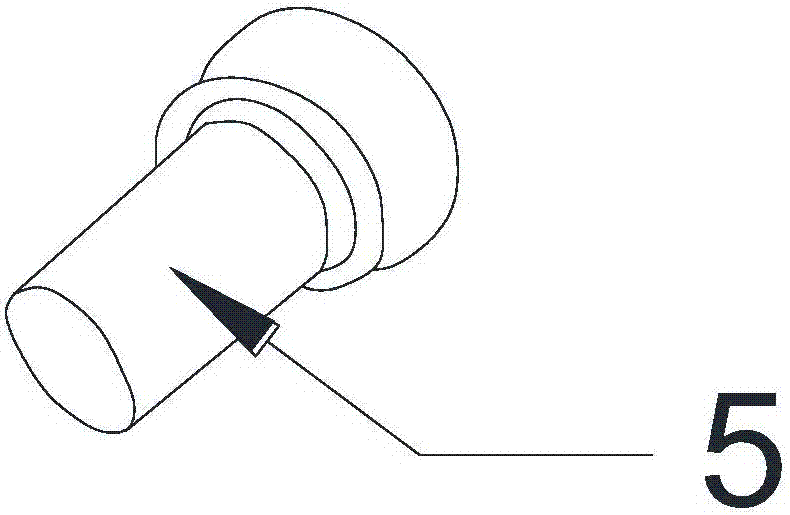

[0025] A method for adjusting damping and eliminating noise of a violin, comprising: coating a 0.15 mm thick nano-coating on the contact surface of the end plug 5 and the end wood 1, and then drying under hot air at 160° C. for 25 minutes.

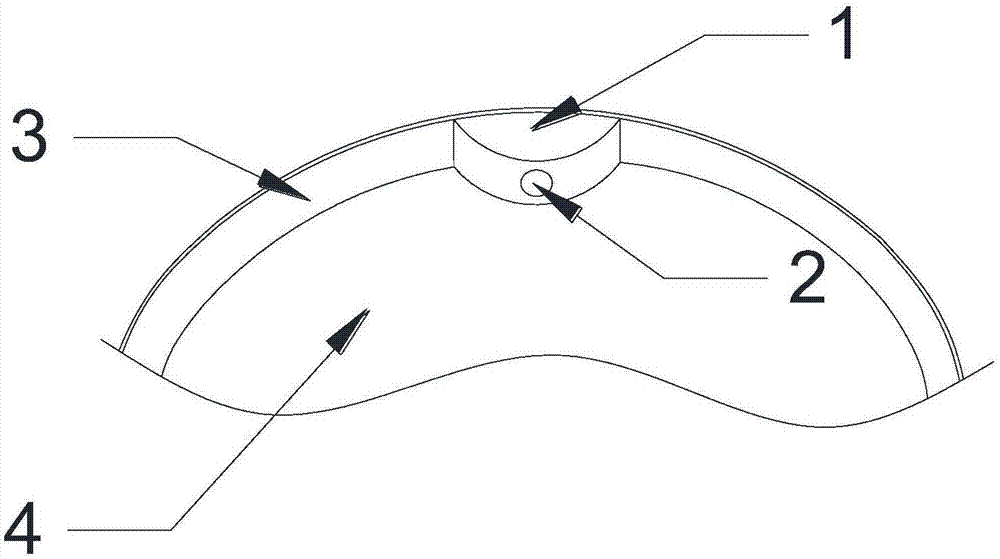

[0026] The tail wood 1 is provided with a tail plug hole 2 that runs through the music tail wood 1, and the tail plug 5 is inserted into the tail plug hole 2 through the opening on the side plate 3, so only the tail plug 5 is coated with nano-coating. There is no need to dismantle the panel or back panel 4, just take off the tail plug 5, apply nano-coating on the tail plug 5, and put it back into the tail plug hole 2 after the nano-coating dries, the operation is simpler and more convenient, and the operation is also more difficult reduce.

[0027] Adopt the method that embodiment 3 provides to carry out coating process respectively to the tail plug 5 of five old violins, contrast the piano sound of same violin before and after processing,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com