Upper shell machine installing mechanism for oscillating motor

A technology of vibrating motors and mounting mechanisms, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of low efficiency of buckle shells, etc., and achieve the effect of ensuring accuracy and preventing excessive oil injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

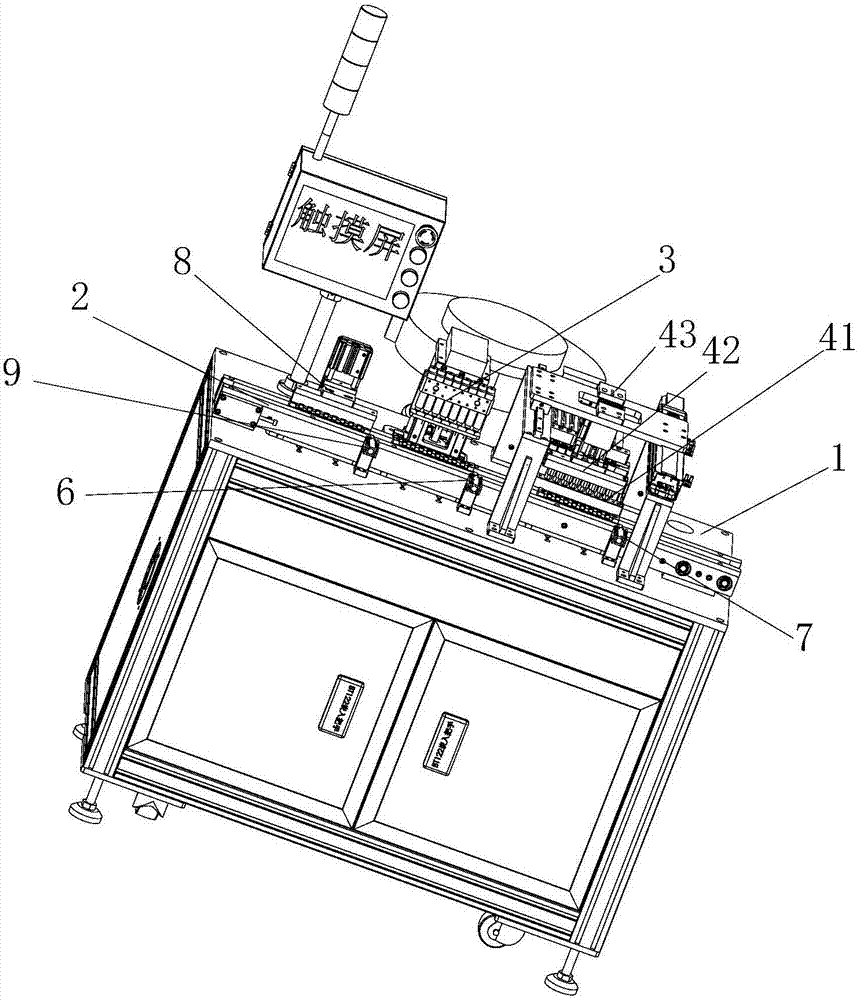

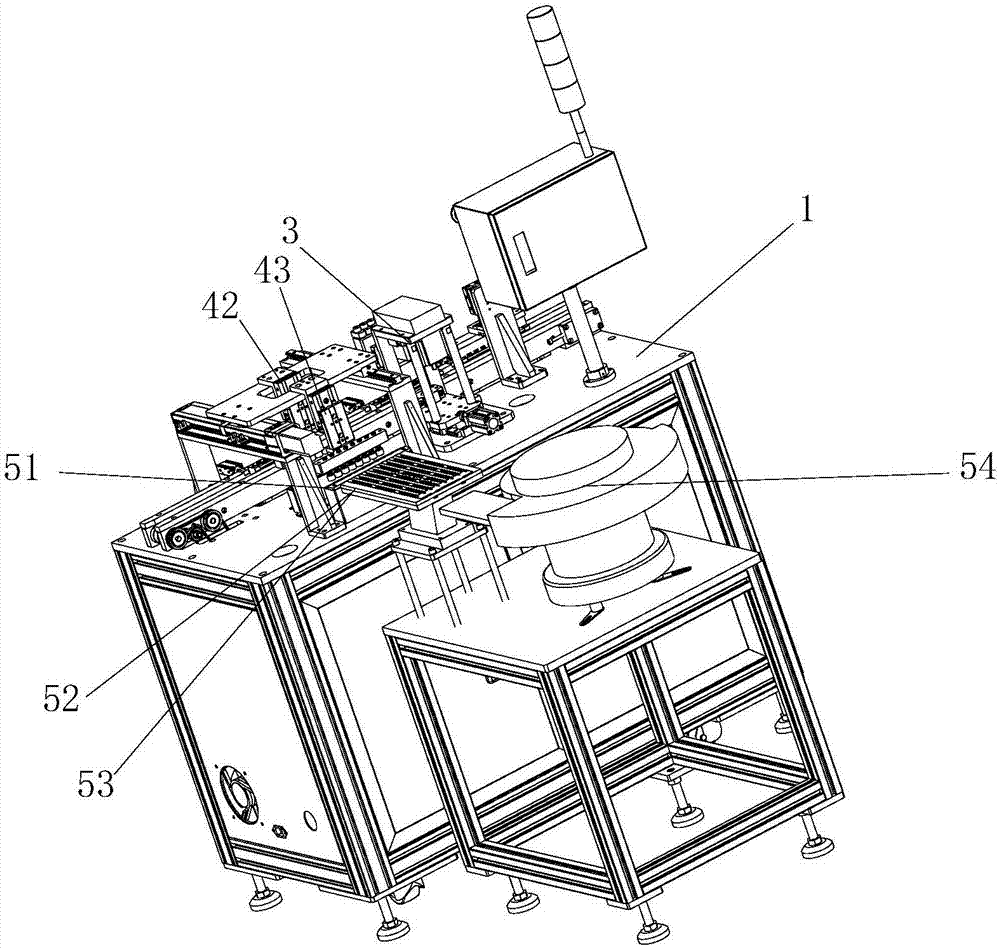

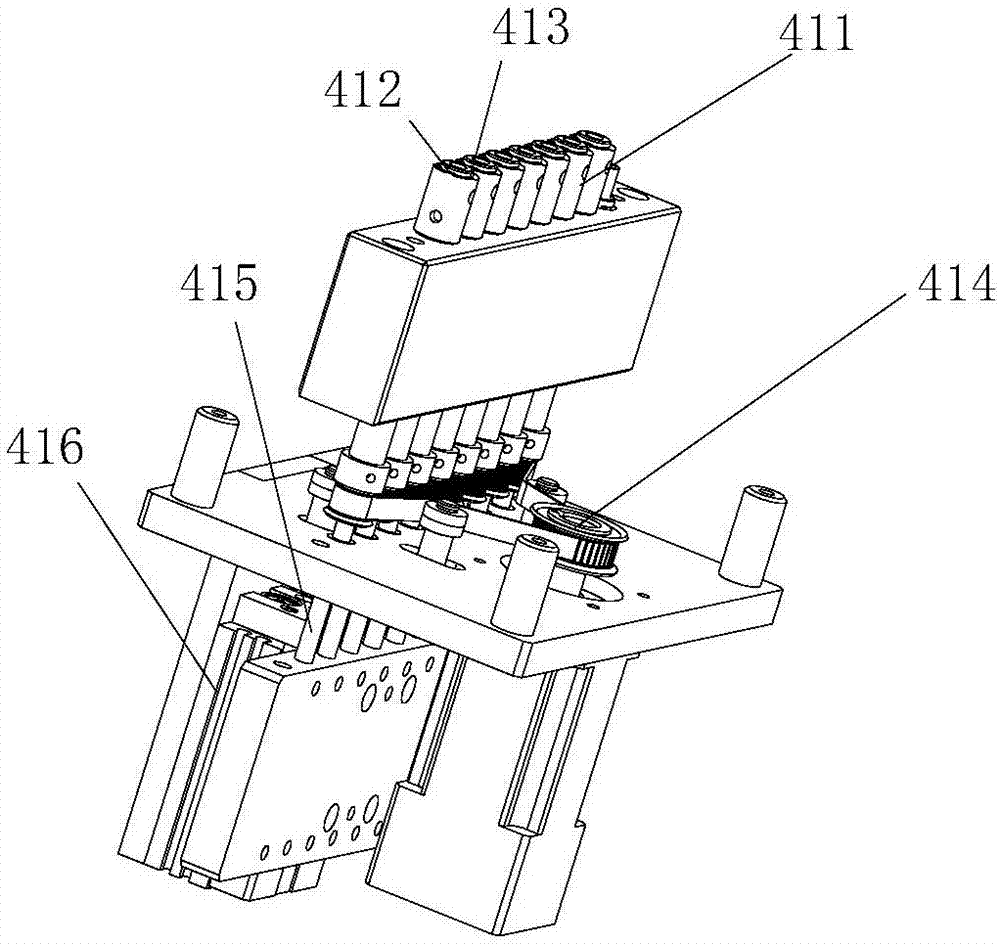

[0022] Such as Figure 1 to Figure 2 The shown upper casing machine installation mechanism for vibration motors includes a frame 1, on which a transmission device 2 for transferring turnover jigs is arranged, and one side of the transmission device 2 is respectively installed along the transmission direction of the transmission device 2 The oiling device 3 and the upper casing device also include a vibrating feeding mechanism for conveying the upper casing to the upper casing device. The side of the transmission device 2 is also provided with a first blocking mechanism 6 and a second blocking mechanism 7. The first blocking mechanism Mechanism 6 includes the first photoelectric sensor that detects whether the turnover fixture is in place and the first blocking cylinder that blocks the turnover fixture, and the second blocking mechanism 7 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com