A method for preparing molybdenum oxide-modified quaternary sulfide quantum dot photocatalysts

A technology of photocatalysts and quantum dots, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The preparation of the CuInZnS quantum dot photocatalyst modified by the molybdenum oxide group of embodiment 1

[0018] Take by weighing 0.1357 gram of copper acetate, 0.186 gram of zinc acetate, 0.649 gram of indium nitrate, and a certain amount of sodium molybdate is mixed and dissolved in 4 milliliters of water. Here, in order to synthesize samples containing molybdate radicals in different proportions, the addition of indium nitrate is fixed and adjusted. Add the amount of sodium molybdate (the molar ratio of sodium molybdate / indium acetate is 0.05 / 1-0.15 / 1). Add 0.244 g of thioacetamide solution, mix evenly by ultrasonic, react at 110°C for 4 hours, cool to room temperature, and centrifuge for the first sample and ethanol volume ratio of 1 / 1, and then dissolve the centrifuged sample with a small amount of water Add ethanol to precipitate and centrifuge for the second time, and the third washing and centrifugation is similar to the second time, first dissolve in wa...

Embodiment 2

[0019] Characterization analysis of the CuInZnS quantum dot photocatalyst modified by the molybdenum oxide group of embodiment 2

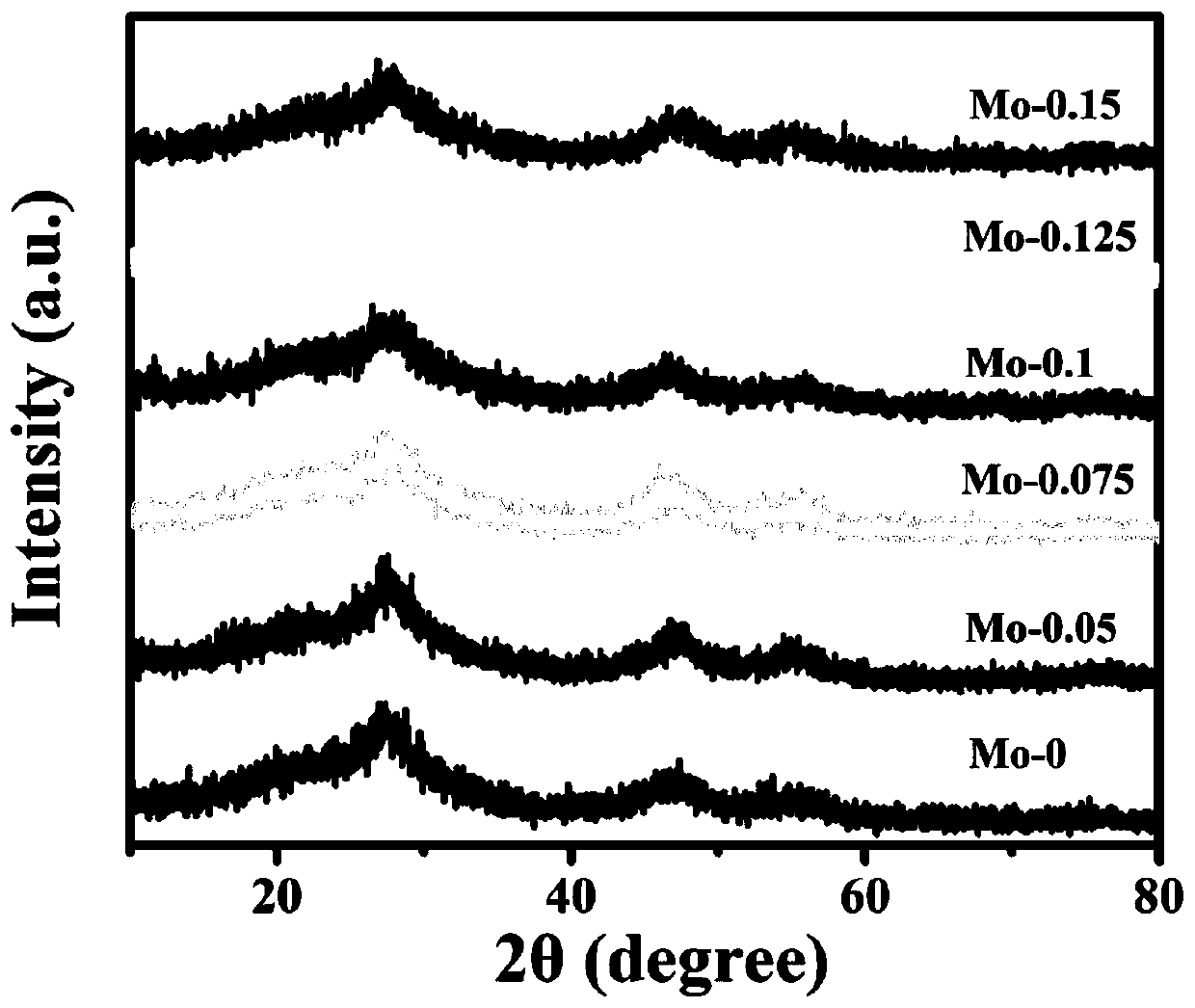

[0020] Such as figure 1 As shown, it can be seen from the figure that with the increase of the molybdenum oxide content, the diffraction main peak of the molybdenum oxide modified CuInZnS quantum dot photocatalyst has no obvious change.

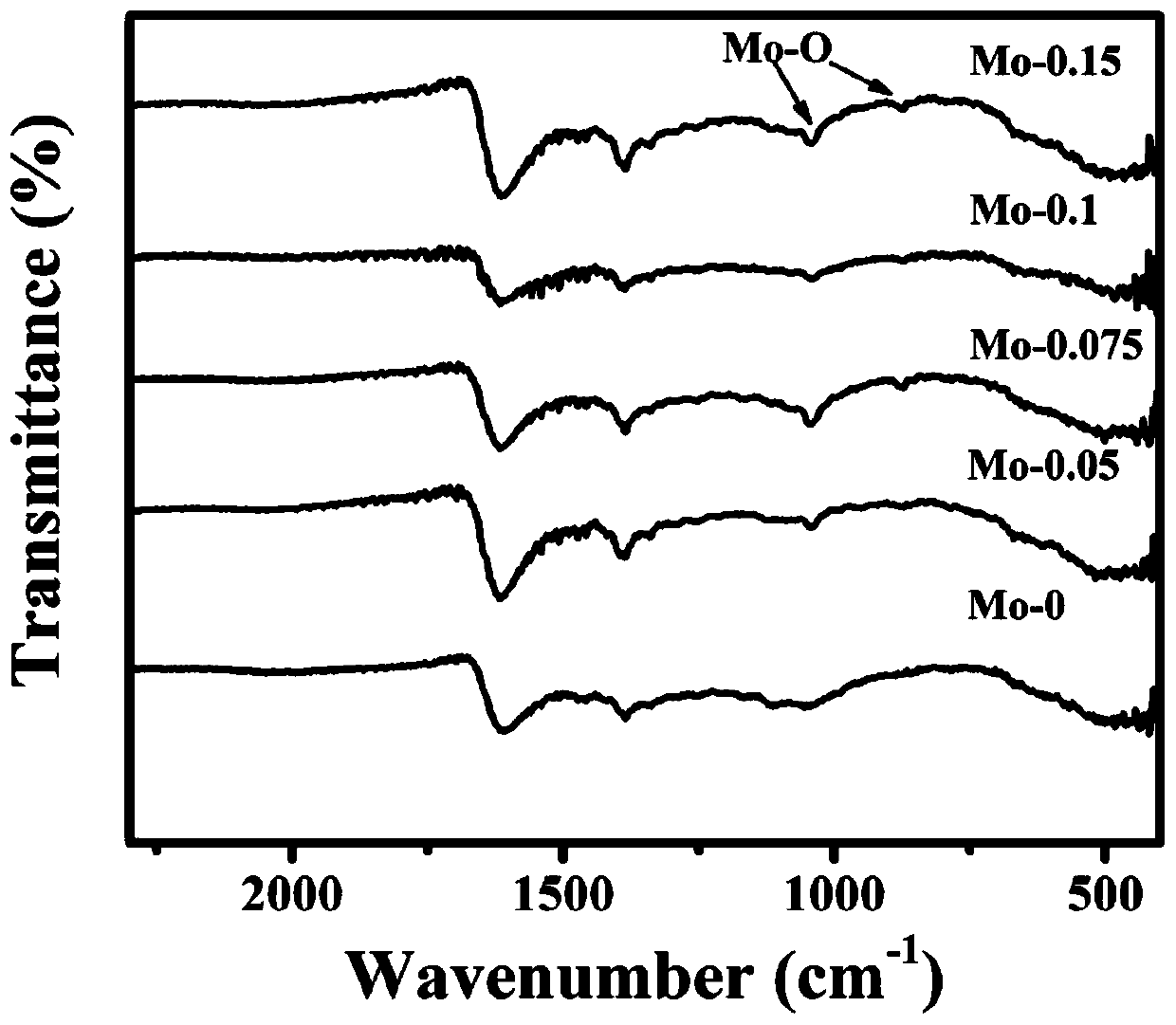

[0021] Such as figure 2 As shown, it can be seen from the figure that with the increase of molybdenum oxide content, the peak of Mo-O bond appears and strengthens, indicating that molybdenum oxide has successfully modified CuInZnS quantum dots.

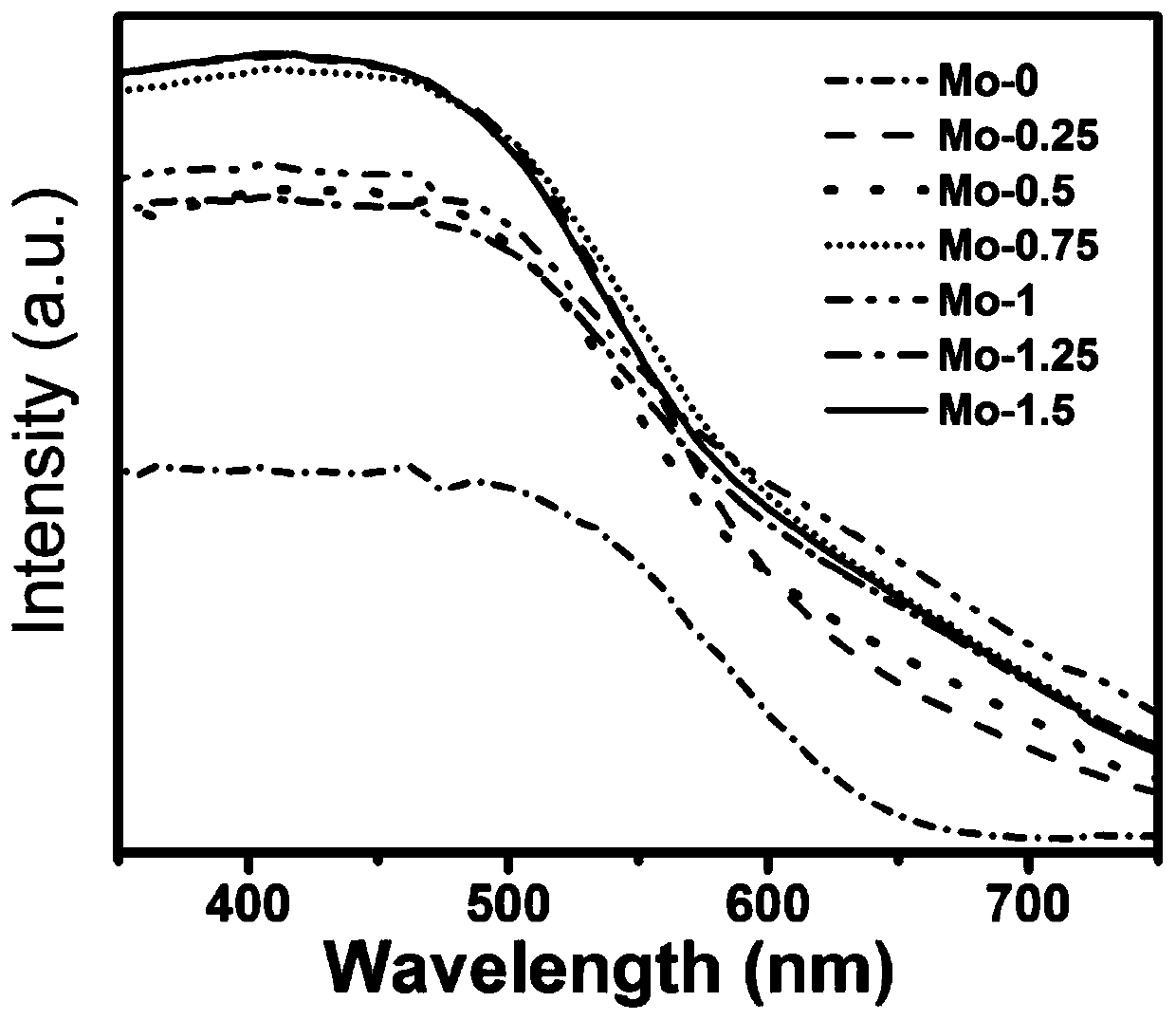

[0022] Such as image 3 As shown, it can be seen from the figure that with the increase of the molybdenum oxide content, the light absorption is red-shifted, that is, the increase of the molybdate group makes the band gap of the quantum dots decrease and the light absorption increases.

[0023] Such as Figure 4 As shown, it can be seen from the figure that with the ...

Embodiment 3

[0024] Example 3 Visible light catalytic activity experiment of molybdenum oxide modified CuInZnS quantum dot photocatalyst

[0025] (1) Weigh 20 mg of molybdenum oxide-modified CuInZnS quantum dot photocatalyst, place it in a photocatalytic hydrogen production reactor, add 15 ml of water and an appropriate amount of sacrificial agent and sonicate for 20 minutes.

[0026] (2) The amount of hydrogen gas generated was measured every hour by gas chromatography.

[0027] (3) by Figure 4 It can be seen that the prepared photocatalyst has excellent visible light catalytic activity, especially the Mo-0.1 sample has much higher hydrogen production performance than Mo-0.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com