Method of preventing dry heating of electric kettle and electric kettle

An electric kettle and anti-dry technology, which is applied in the direction of boiling water utensils, cooking utensils, household appliances, etc., can solve the problems of large error, disconnection of electric kettle power supply, affecting the anti-dry function of the kettle, etc., and achieves fast response Fast and error-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

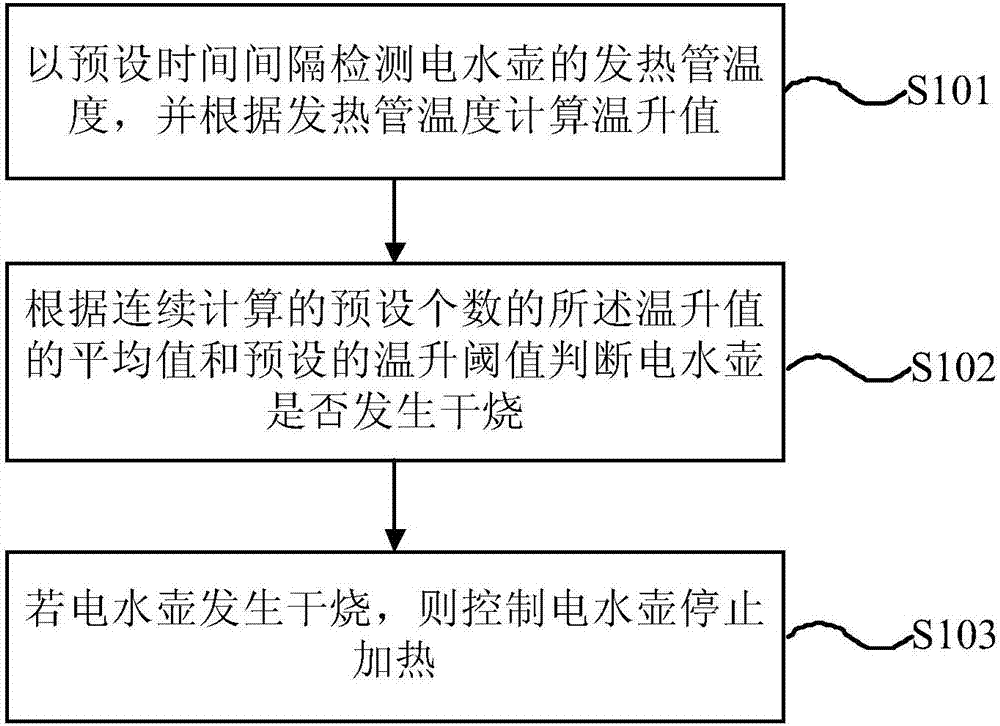

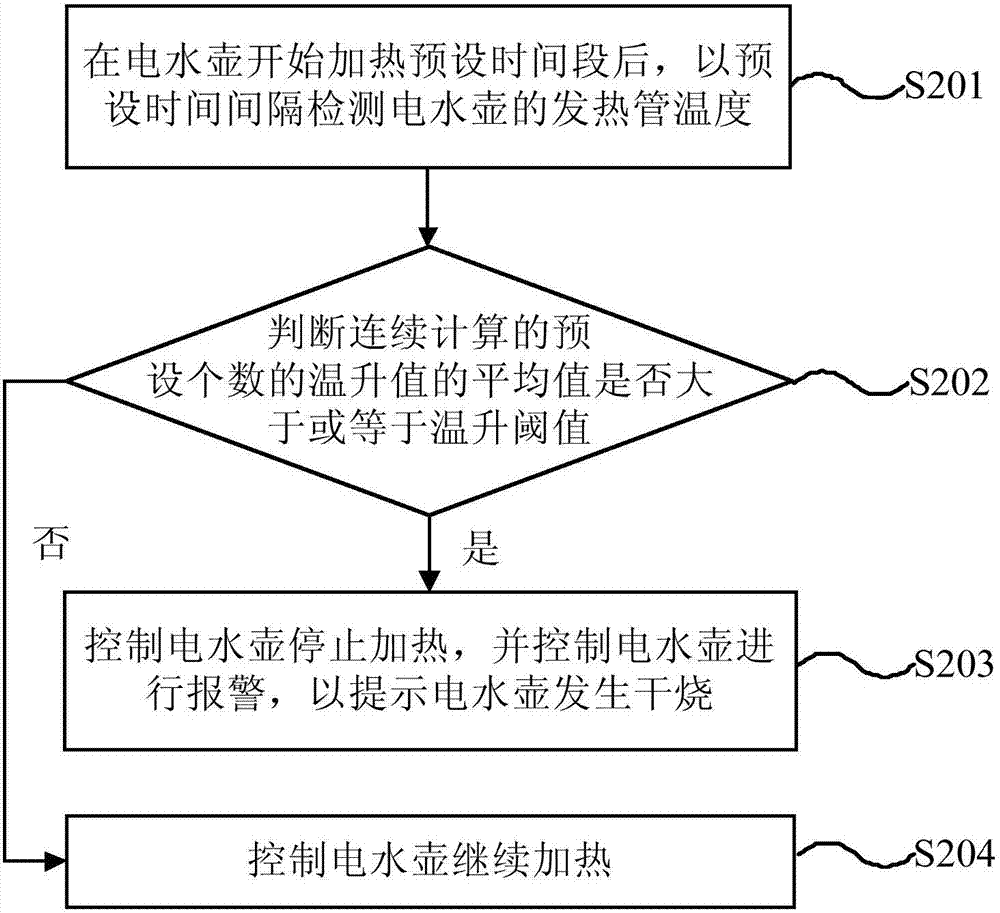

[0024] figure 1 A schematic flow chart of the electric kettle anti-dry boiling method provided by an embodiment of the present invention, as figure 1 As shown, the method provided in this embodiment may include the following steps:

[0025] S101. Detect the temperature of the heating tube of the electric kettle at a preset time interval, and calculate the temperature rise value according to the temperature of the heating tube.

[0026] Specifically, there is a heating device and a controller for controlling the operation of the heating device between the kettle body and the bottom cover in the electric kettle. The heating device is generally a heating tube, and the heating tube is close to the inner tank of the kettle body; For the pipeline connected with the inner tank, the heating tube is closely attached to the pipeline; or, the heating tube is connected with the inner tank. After the electric kettle is powered on, the heat pipe generates heat to heat the liquid in the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com