Boom sprayer

A boom spraying and spraying system technology, which is applied in the device, application, animal husbandry and other directions of capturing or killing insects, can solve the problems of low work efficiency, broken boom, waste of resources and pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

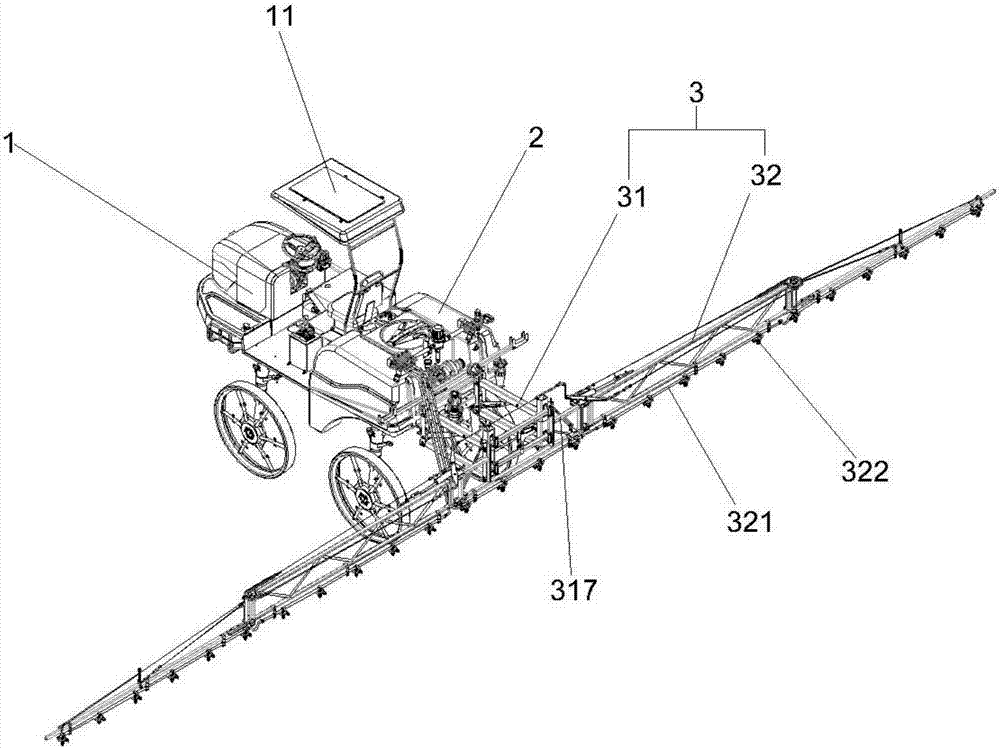

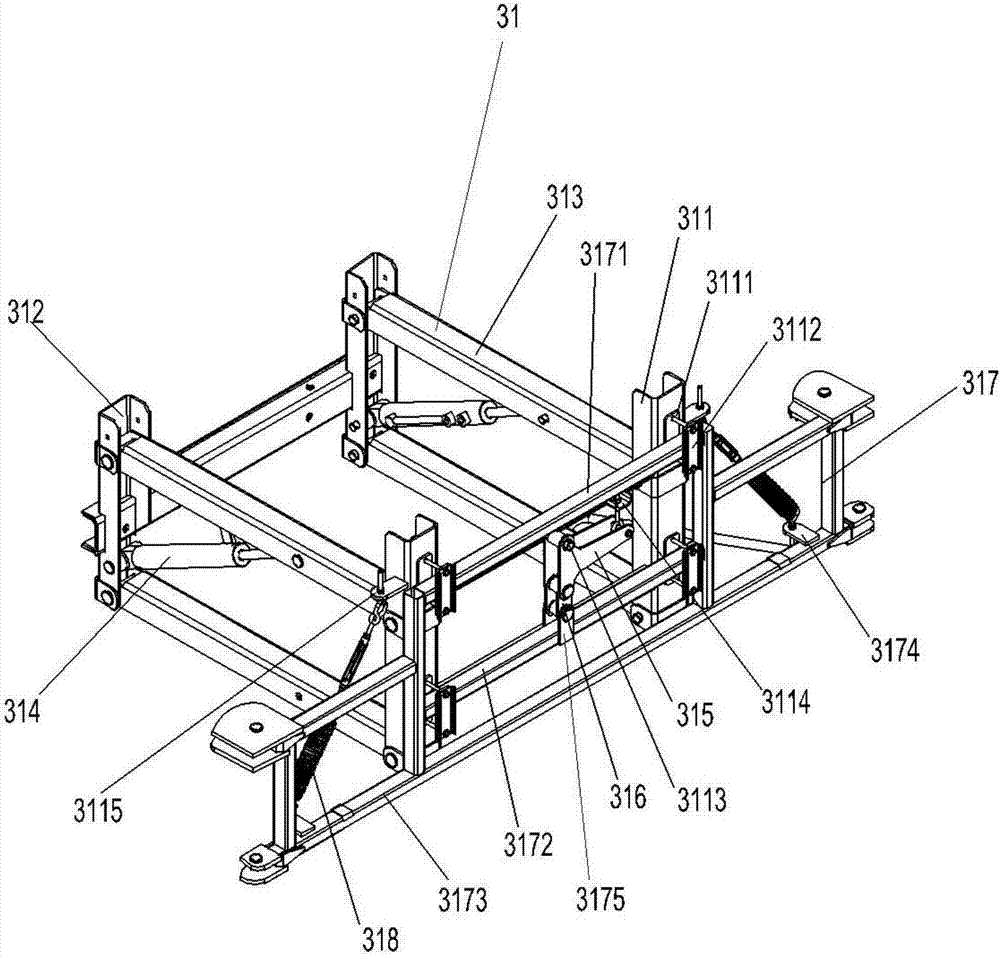

[0024] see Figure 1-4 , a boom sprayer, comprising a spray locomotive (1) equipped with a power drive system, the tail of the spray locomotive (1) is equipped with a liquid medicine mixing system (2) and a spray system (3);

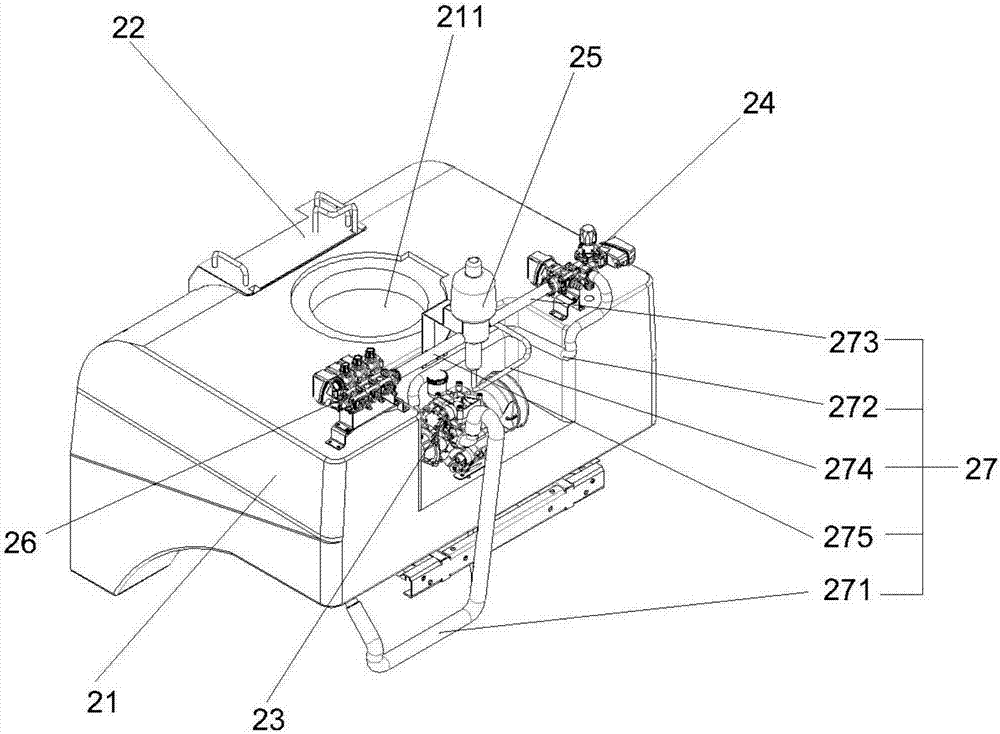

[0025] The liquid medicine mixing system (2) includes a water tank (21), a raw medicine tank (22), a diaphragm pump (23), a solenoid valve (24), a proportional pump (25), a three-way valve (26) and pipe fittings (27); The original medicine box (22) is arranged on the front side of the water tank (21) close to the spray locomotive (1), and the diaphragm pump (23), solenoid valve (24), proportional pump (25) and three-way valve (26) are arranged on the water tank (21) the other side; pipe fittings (27) include first pipe fittings (271), second pipe fittin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com