Intelligent control handling robot

A handling robot and intelligent control technology, applied in the field of robots, can solve the problems of low utilization rate of garbage bags, low degree of automation, poor ground hygiene, etc., and achieve the effects of excellent mobility, excellent installation and wide application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

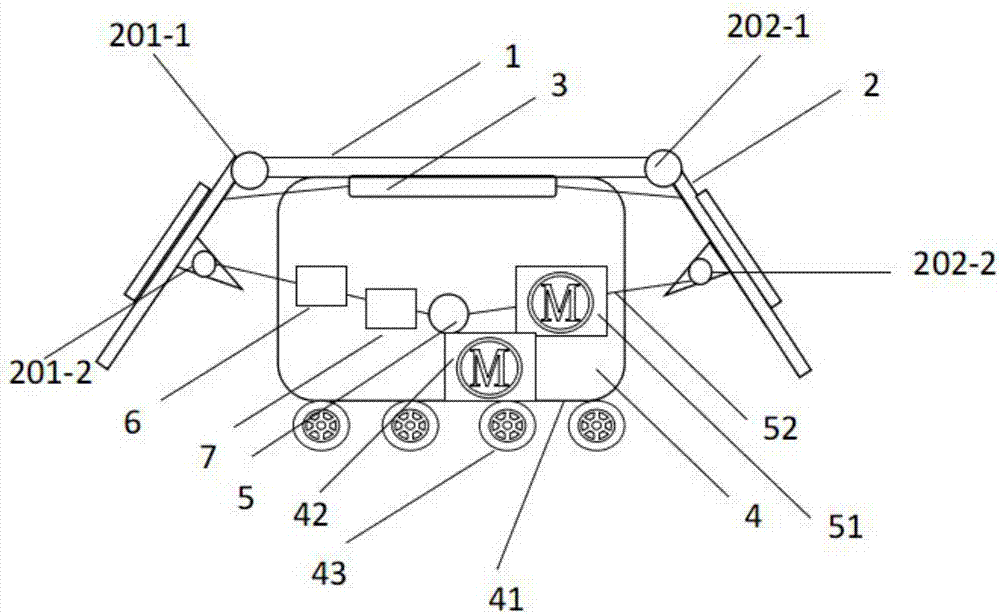

[0023] An intelligent control handling robot, such as figure 1 As shown, the transfer robot includes a first loading platform 1, and a storage battery 3 is fixed on the bottom of the loading platform 1, and the storage battery 3 is connected to the solar photovoltaic panel group 2 to store the solar energy of the solar photovoltaic panel group. Converted electric energy; the solar photovoltaic panel group 2 is composed of N pairs of solar photovoltaic panel groups, and each solar photovoltaic panel group includes two oppositely arranged two solar photovoltaic panels;

[0024] The handling robot also includes a motion mechanism 4 connected to the storage battery. The motion mechanism includes a support platform 41, a drive motor 42 and more than one wheel assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com