A compact vacuum pump

A vacuum pump, compact technology, applied in the direction of pumps, piston pumps, pump components, etc., can solve the problems of drive circuit board, drive controller damage, unable to detect the air pressure of the pumped container, very troublesome to use, etc., to achieve strong adaptability , Simple repair and maintenance, convenient installation and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

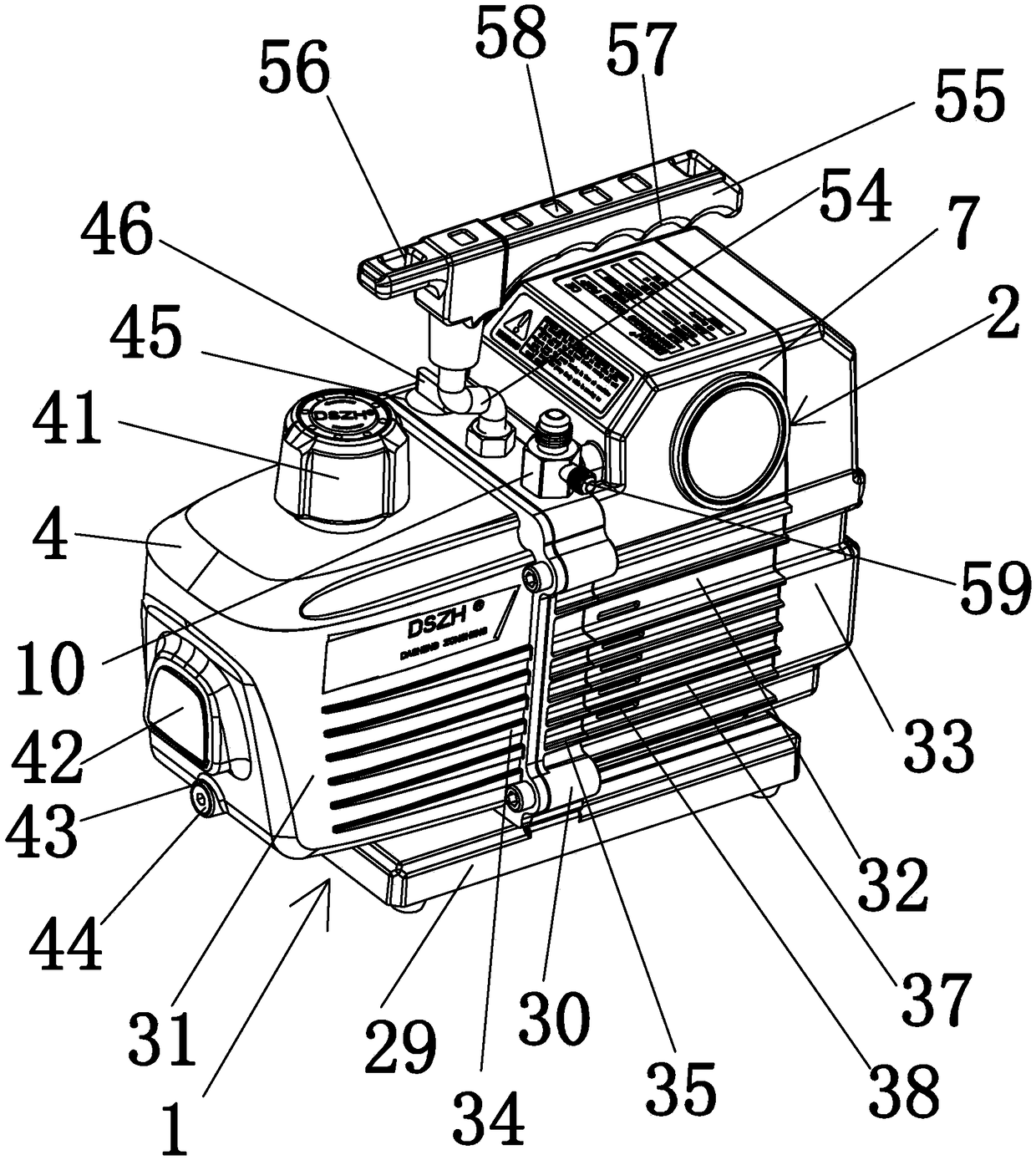

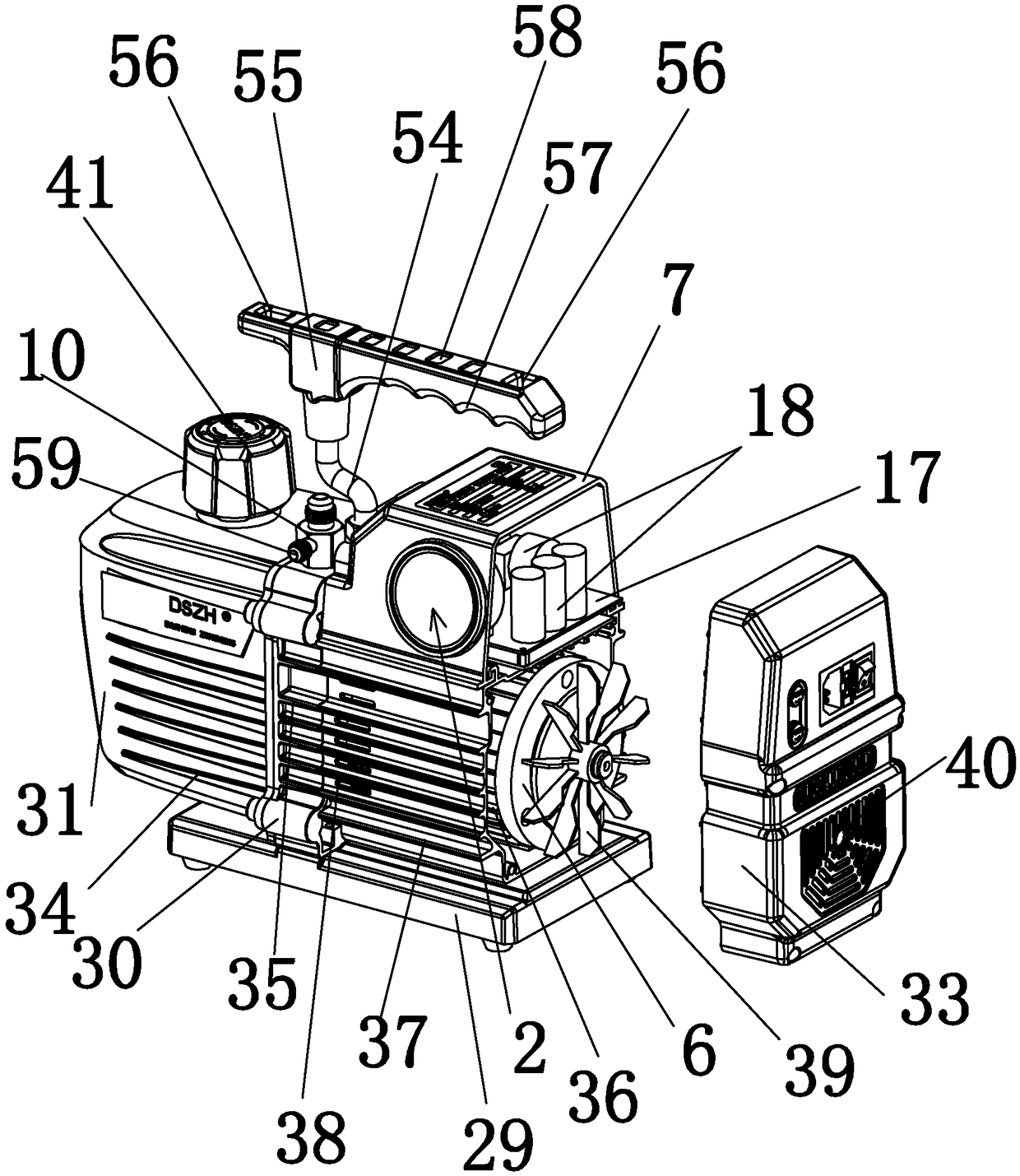

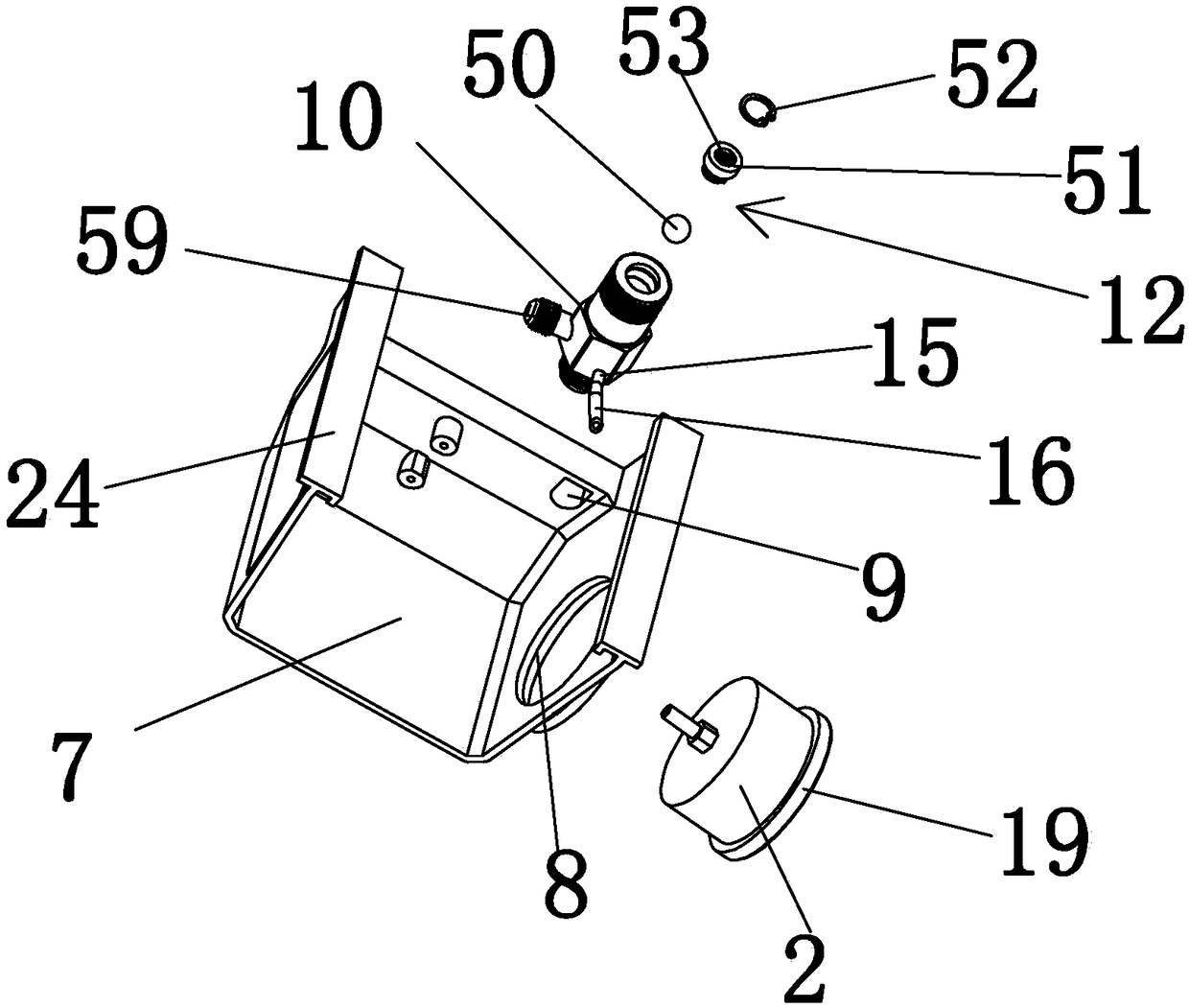

[0030] like Figure 1-6 As shown, a compact vacuum pump includes a vacuum pump main body 1 and an air pressure gauge 2, a protective cover 7 is detachably and fixedly installed on the casing of the vacuum pump main body 1, and a mounting hole 8 and a through hole 9 are opened on the protective cover 7, The air pressure gauge 2 is a digital display pressure gauge. The digital display pressure gauge includes a circuit board 20 and a digital display screen 21 fixedly connected to the circuit board 20. The circuit board 20 is arranged in the protective cover 7, and the digital display screen 21 is embedded and installed. In the hole 8, the measurement port of the digital display pressure gauge is arranged on the circuit board 20, the inner side wall of the protective cover 7 is fixedly connected with a fixing strip 22, and the fixing strip 22 is arranged next to the installation hole 8, and the digital display screen 21 It is fixedly installed on the circuit board 20, and the circ...

Embodiment 2

[0036] like Figure 7-10 As shown, compared with Embodiment 1, the difference between Embodiment 2 is that the air pressure gauge 2 adopts a digital display pressure gauge, which includes a circuit board 20, a digital display screen 21 fixedly connected to the circuit board 20, and the circuit board 20. The board 20 is arranged in the protective cover 7, the digital display screen 21 is embedded in the installation hole 8, the measurement port of the digital pressure gauge is arranged on the circuit board 20, and the inner side wall of the protective cover 7 is fixedly connected with a fixing strip 22. , the fixing bar 22 is arranged beside the installation hole 8 , the digital display screen 21 is fixedly installed on the circuit board 20 , and the circuit board 20 is fixedly installed on the fixing bar 22 by screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com