Transportation system and construction method for inclined shaft with small section and long steep slope

A transportation system and small-section technology, which is applied in the small-section long steep slope inclined shaft transportation system and construction field, can solve the problems of long construction period, small end face of spillway tunnel, and difficulties, so as to enhance climbing ability, ensure engineering safety and save energy. The effect of the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

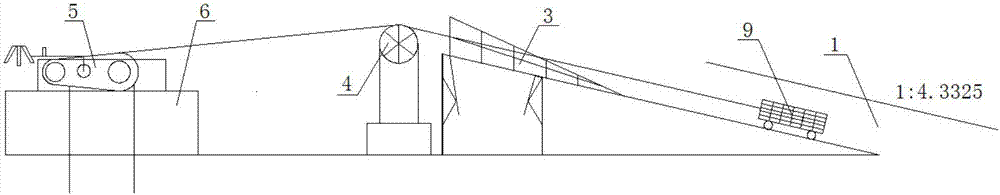

[0028] The small-section and long steep slope inclined shaft transportation system of the present invention, the inclined shaft 1 includes a high entrance section, a low exit section and an intermediate section, such as figure 1 , the longitudinal slope of the entrance section of inclined shaft 1 is 1:4.325.

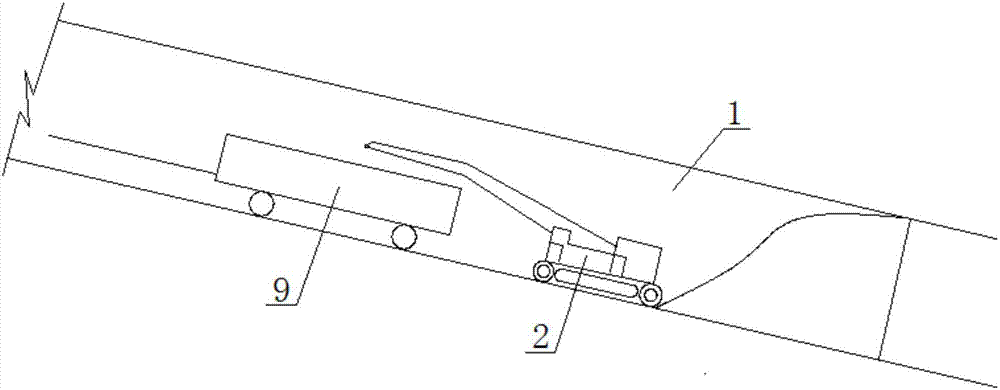

[0029] Such as figure 2 , The slag removal machine 2 is placed on the working face in the entrance section of the inclined shaft 1, and the slag removal machine 2 is used to transfer the hole slag on the working face to the mine car, wherein the mine car is a side unloading mine car 9. Such as figure 1 A slag unloading platform 3 is set at the entrance of the inclined shaft 1, and a fixed pulley 4 and a hoist 5 are installed on the side of the slag unloading platform 3 opposite to the inclined shaft 1, wherein the hoist 5 is installed on the ground anchor platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com