Construction steel platform mould base system with double tuned mass vibration reduction function

A technology of tuning mass and steel platform, which is applied in non-rotational vibration suppression, processing of building materials, construction, etc. It can solve the problems of not having tuned mass dampers and building structures that cannot swing relative to each other, and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

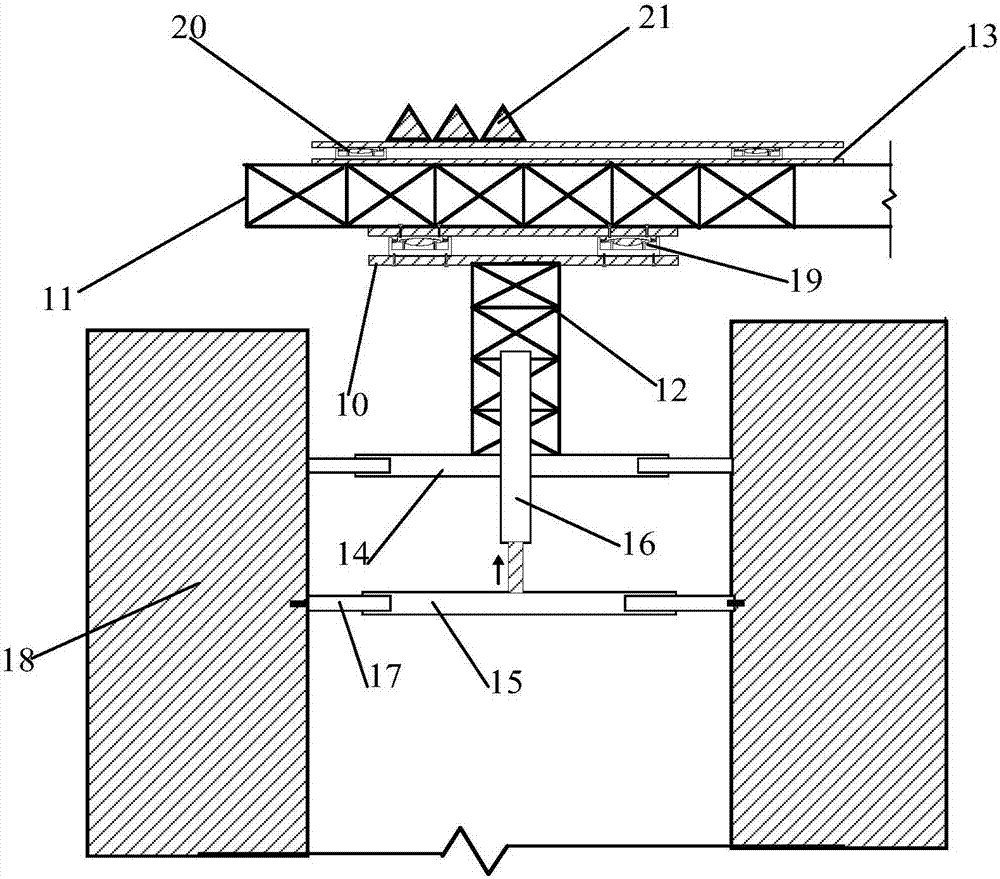

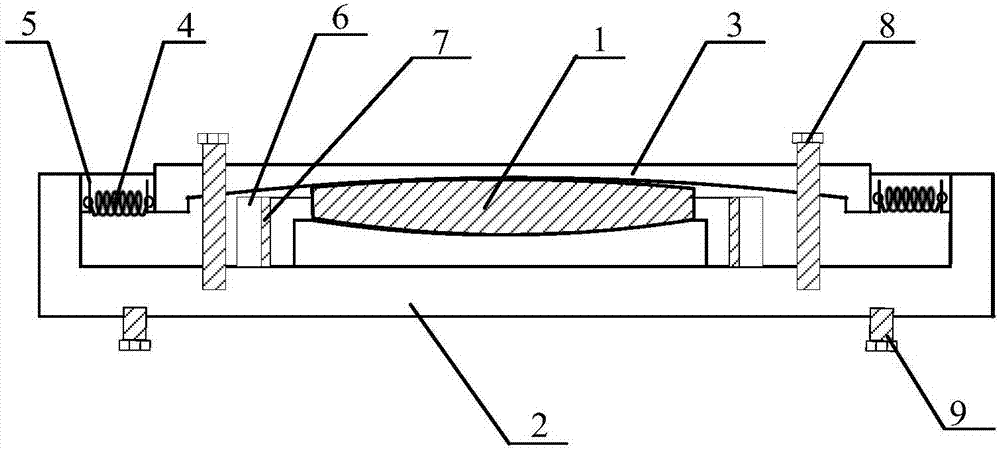

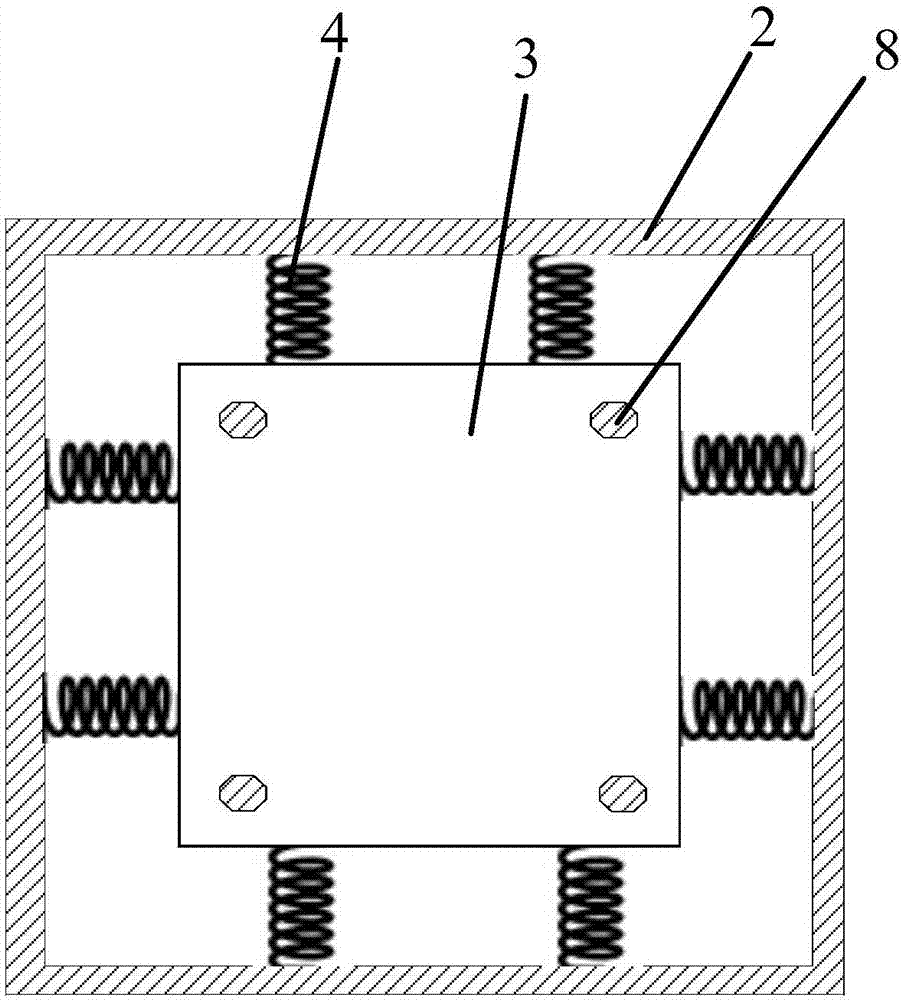

[0034] In the following, a high-rise under construction is taken as an example to describe in detail how the invention reduces the vibration of the main structure under the action of an earthquake.

[0035] The building is a comprehensive super high-rise building integrating five-star hotels, shopping malls, and high-end office buildings. It is a core tube-concrete steel tube structure with 71 floors above ground and 6 floors underground, with a height of 318 meters. According to the plane area of the core tube, the specifications of each component of the steel platform formwork system are determined to meet the requirements in the technical plan. Then, the construction steel platform formwork system with double tuning mass vibration damping function is attached to the core tube for construction. Whenever the core tube is built with 5 floors, the first-order natural vibration frequency of the main structure is measured. During the construction process, the entire steel platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com