A preparation method of flexible carbon fiber with superamphiphobic properties

A super-amphiphobic and carbon fiber technology, which is applied in the fields of carbon fiber, fiber treatment, fiber chemical characteristics, etc., can solve the problems that affect the practical use of super-amphiphobic self-cleaning surfaces, helplessness, and no industrialization, etc., to achieve adjustable morphology, The effect of simple process and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

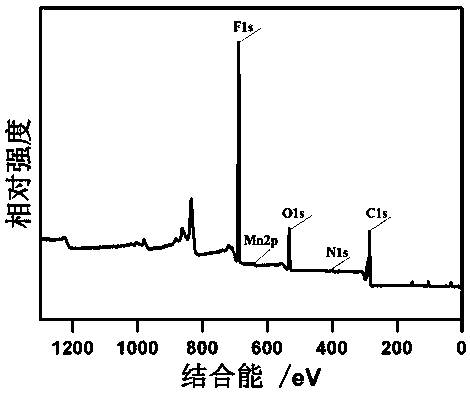

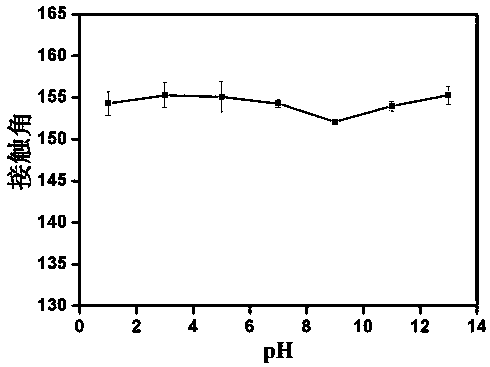

[0024] 1. Preparation of nano-spun fibers:

[0025] Dissolve polyacrylonitrile and manganese acetylacetonate with different mass ratios in a certain amount of DMF solvent according to the proportions in the table, and stir thoroughly for 10 hours to obtain multiple electrospinning solutions with a mass fraction of 10%, and then perform electrospinning respectively Silk.

[0026] The following table shows an example of the feed ratio of polyacrylonitrile and manganese acetylacetonate: (unit: mg)

[0027] Polyacrylonitrile Manganese acetylacetonate DMF solvent example 1 1200 150 10800 Example 2 1200 360 10800 Example 3 1200 600 10800

[0028] Use a syringe to draw an appropriate amount of electrospinning solution, and install a spinning needle on the top of it, and connect it to the positive pole of the power supply. Receive it with aluminum foil, and connect it to the receiving plate as the negative pole. The flow rate of the spinn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com