Automatic waistband elastic ribbon feeding machine

A kind of elastic and automatic technology, which is applied in the direction of cloth feeding mechanism, sewing machine components, textiles and paper making, so as to improve work efficiency and prevent deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

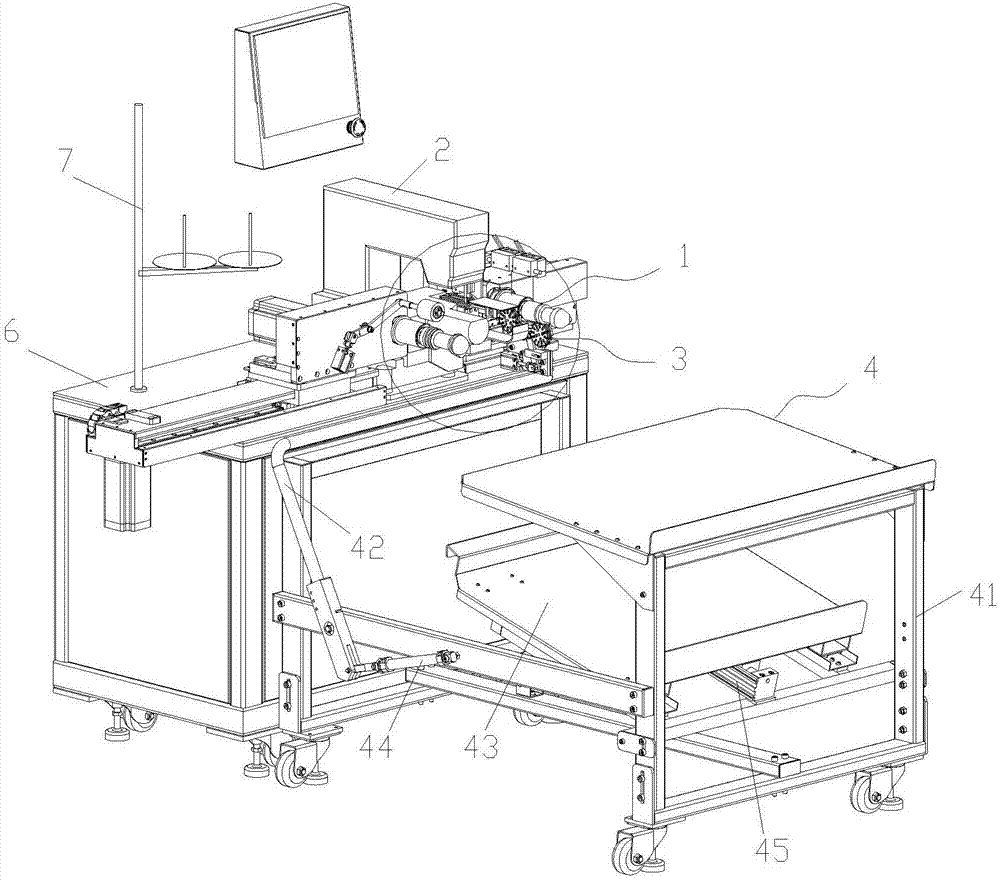

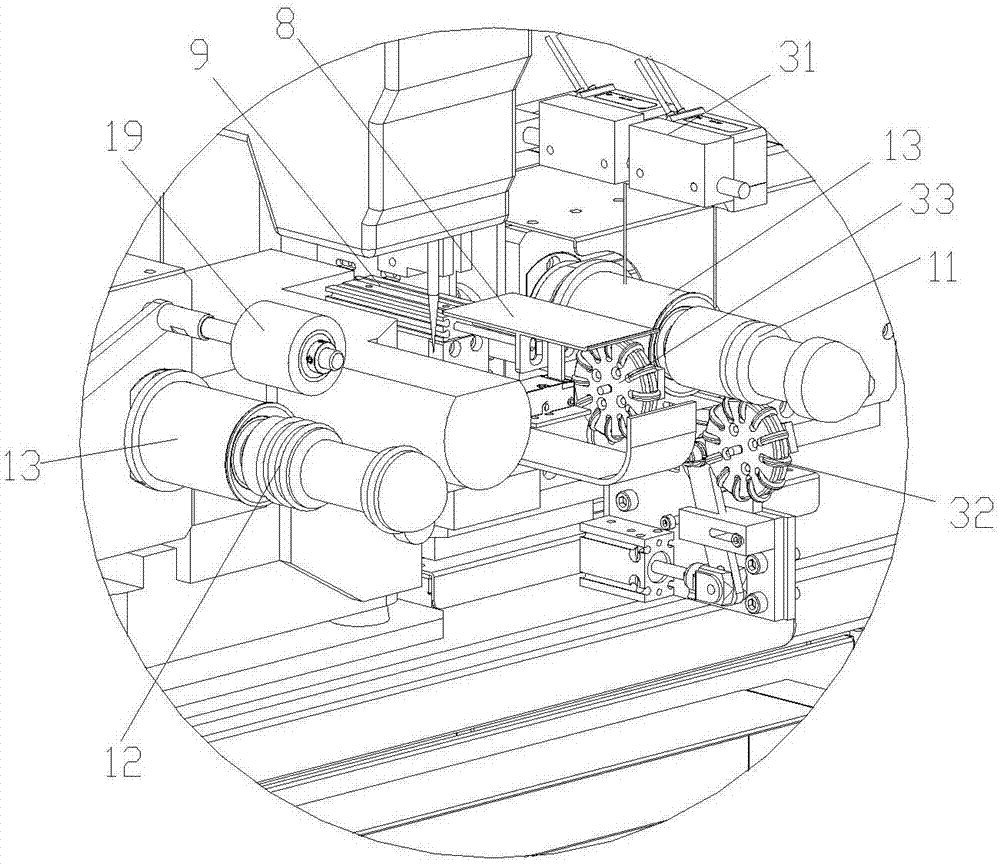

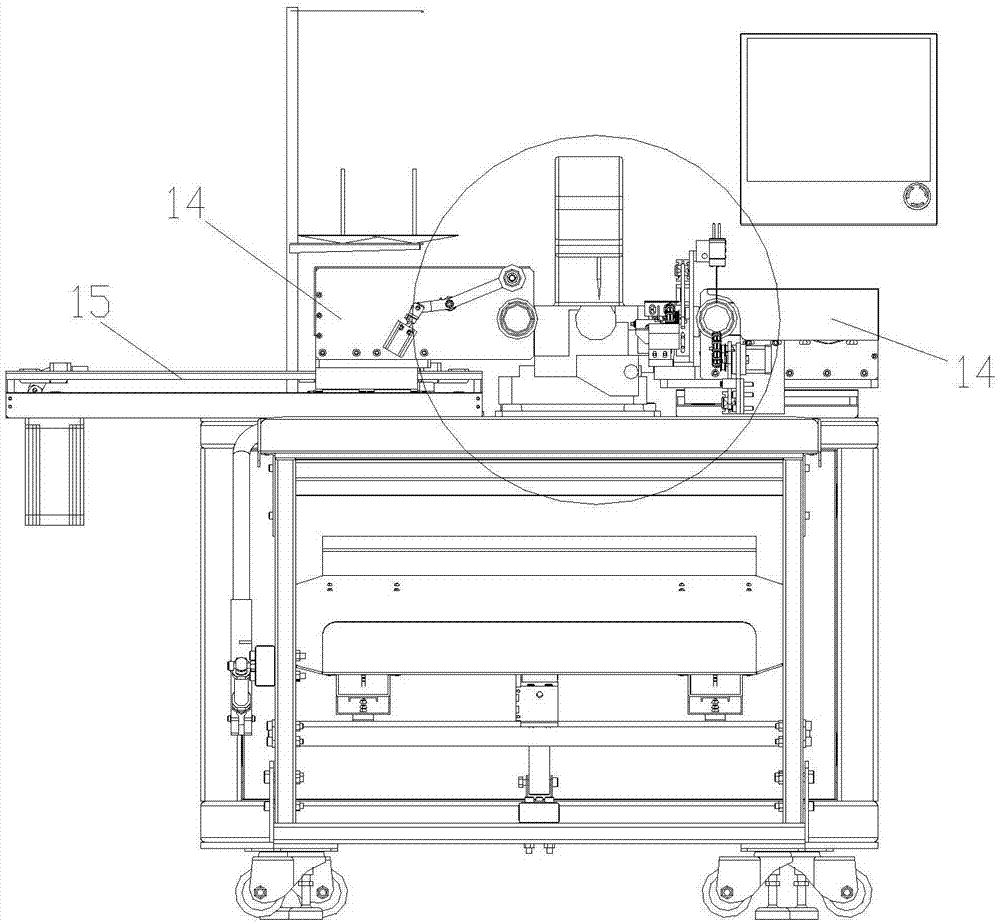

[0019] Please refer to the attached Figures 1 to 6 , the embodiment of the present invention includes:

[0020] A trouser waist automatic elastic machine, comprising trouser material holding mechanism 1 for expanding and stretching trouser fabric, elastic roller 13 which moves synchronously with the trouser material holding mechanism, and sewing machine 2 for sewing elastic on trouser material 1. Deviation correcting mechanism 3 for adjusting trouser material and elastic track, sensor 5, material receiving mechanism 4, workbench 6, electrical components, control components. Trousers holding mechanism 1, elastic roller 13, needle car 2, deviatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com