A kind of plugging agent and preparation method for plugging malignant leakage formation fractures

A leak-stopping agent and leak-off technology, which is applied in the field of oil drilling, can solve the problems that the leak-stopping agent cannot bridge, reinforce, and stay, etc., and achieve the effects of low price, time saving, and strong plugging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

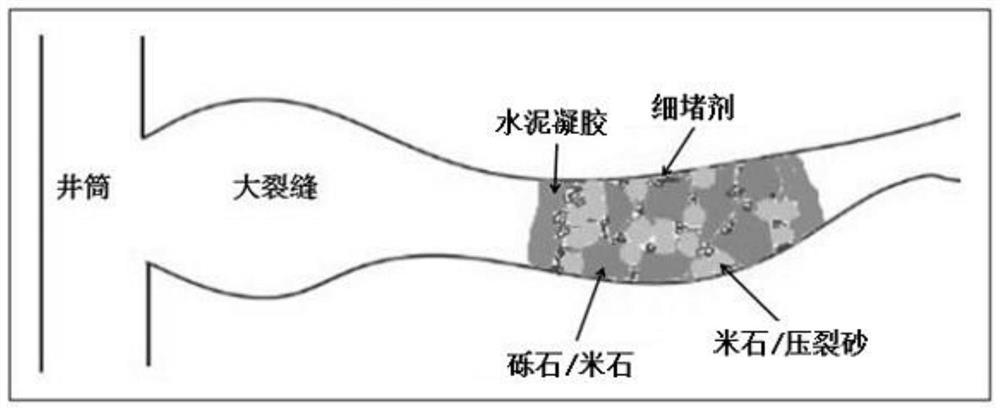

[0025] This embodiment provides a figure 1 The shown lost circulation agent for plugging the formation fractures of malignant loss includes the following components: by mass percentage, 45-56% of oil well G grade cement, 8-12% of gravel, 12-15% of rice stone, 15% -20% fracturing sand, 6-9% fine plugging agent, 1-2% fluid loss reducer, 2-4% external admixture.

[0026] The oil well grade G cement is one or more of oil well high resistance cement, oil well low resistance cement and 425 cement.

[0027] The gravel is one or more of pebbles, white jade, graded crushed stones, sandstones, and flakes, and the particle size of the gravels is 10-40mm.

[0028] The rice stone is one or more of quartz sand, sea glass, sandstone, washed stone, block stone, and stone chips, and the particle size of the rice stone is 4-10mm.

[0029] The fracturing sand is one or more of natural quartz sand, ceramsite sand, yellow sand, and river sand, and the particle size of the fracturing sand is 1-4m...

Embodiment 2

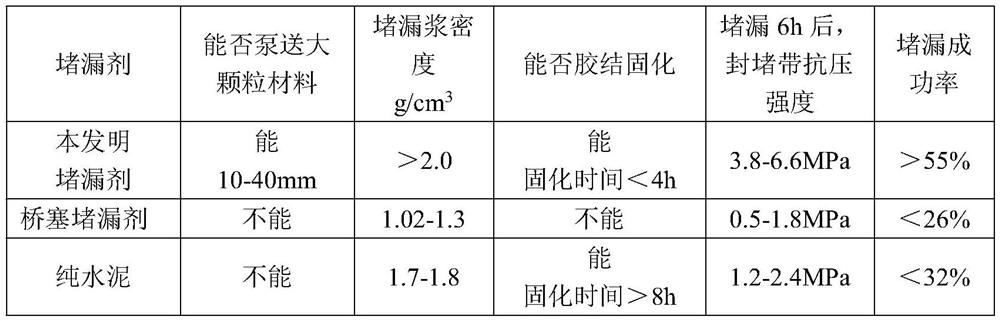

[0042] On the basis of Example 1, this example provides a preferred plugging agent for plugging the fractures in the formation with malignant loss. Magnesite fiber (particle size 0.1-1mm), 3% polyethylene fiber (particle size 0.1-1mm), 1% emulsified asphalt, 2% dihydrate gypsum, after mixing evenly, dry at 70°C for 2 hours , to obtain a binary gel; then add 9% pebbles (15-30mm in particle size), 12% sandstone (4-9mm in particle size), and 15% natural quartz sand (2-4mm in particle size), After mixing evenly, put it in a dryer and dry it at 60°C for 1.5 hours. After cooling, put it into a moisture-proof packaging bag and seal it to obtain a ternary rigid gel, which is used to seal the formation fractures of malignant leakage. After the plugging agent is prepared, use special mixing and strong pumping equipment for petroleum to prepare ternary rigid gel plugging slurry. The water-cement ratio (quality of water / quality of plugging agent) ) is 0.27, and its plugging function is c...

Embodiment 3

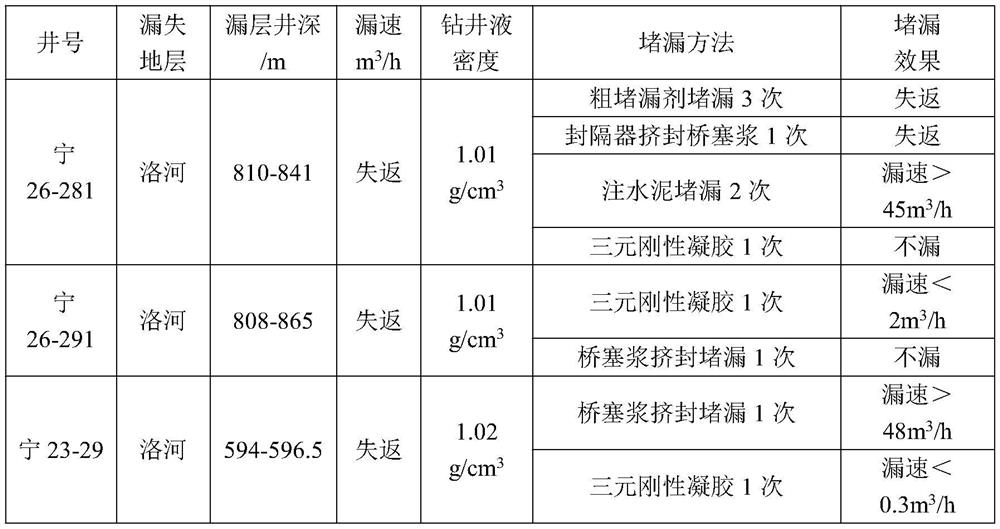

[0046] This example takes Well Ning 26-281 as an example. Well Ning 26-281 is located in Jixian Township, Heshui County, Gansu Province. The vertical depth of the Luohe River is 540-820 meters. Layer 810-841 meters, multiple loss-return leaks occurred successively. Cement was used for plugging twice, packer squeezed the bridge plugging slurry once, and coarse plugging agent was used for plugging three times, all of which failed to achieve the expected plugging effect , the return displacement is only 1 / 3.

[0047] The lost circulation agent of the present invention for plugging the formation fractures of malignant leakage is formulated as follows, by mass percentage, 56% of oil well high-resistance cement, 8% of white jade, 12% of quartz sand, and 15% of pottery Granular sand, 6% brucite fiber, 1% sulfonated bitumen, 2% dihydrate gypsum. After the plugging agent is prepared, use special mixing and strong pumping equipment for petroleum to prepare ternary rigid gel plugging sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com